Aluminum Alloy Injection Molding

Aluminum alloy injection molding (AIM) is a new aluminum alloy forming technology. It is similar to metal injection molding (MIM) technology and is the main branch of powder injection molding (PIM) technology. It is developed from injection molding technology and is the fastest growing and most widely used near-net shape processing technology for aluminum alloy parts in the world.

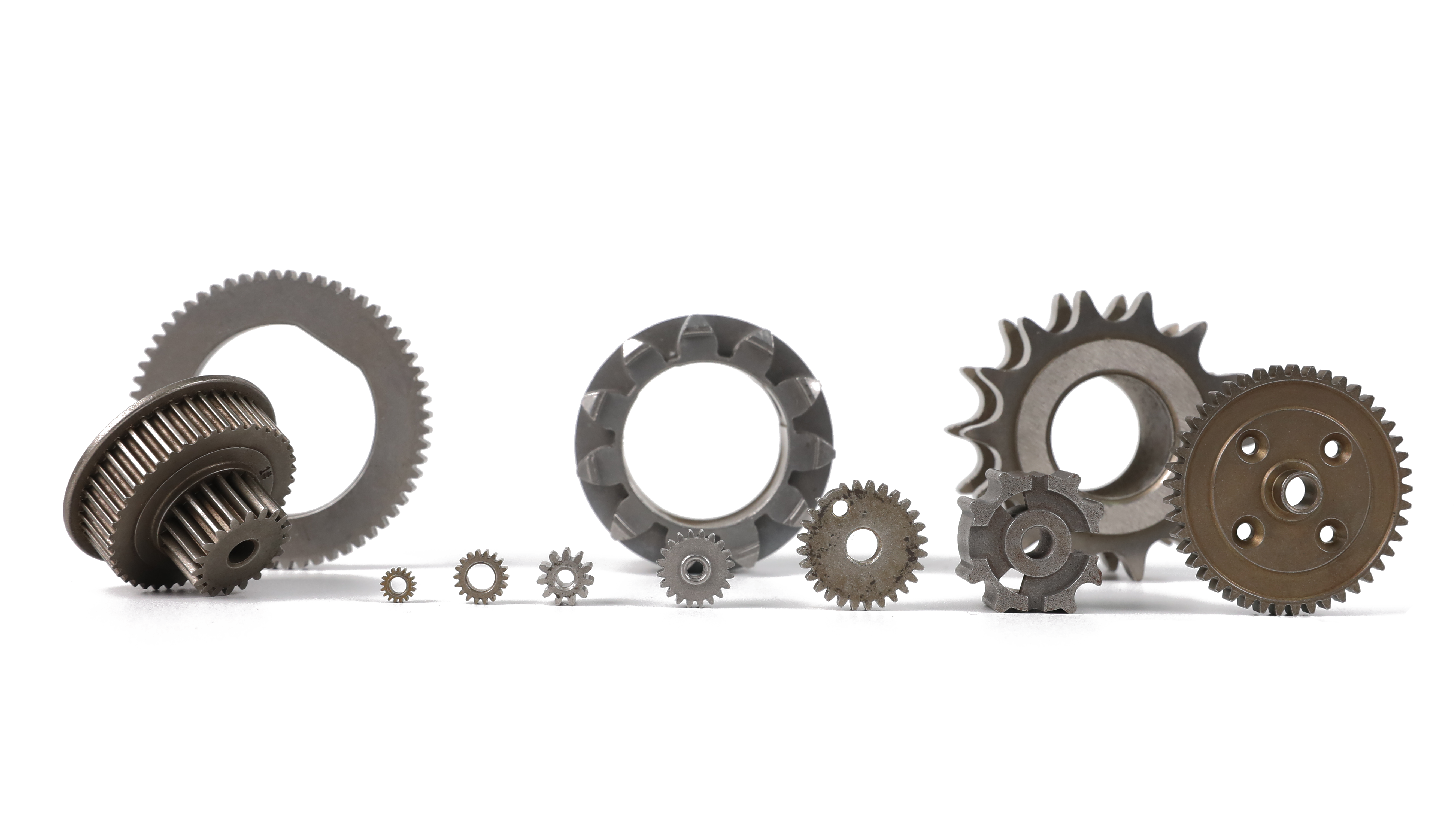

Because the injection process takes place at precise temperatures and pressures, the molded product has extremely high precision and a very uniform density. Aluminum alloy injection molding technology can process and produce extremely complex parts, with small parts as small as 0.1g; the product has a uniform structure, high precision, and smooth surface; the product quality is stable, the production efficiency is high, and it is suitable for mass production.

Since aluminum alloy injection molding has unparalleled advantages in terms of accuracy and efficiency, aluminum's low density makes it particularly attractive in many applications. It has been used in many industries such as navigation, aviation, machinery, automobiles, precision instruments, etc. With the continuous development of the machinery industry, AIM has become the fastest-growing near-net shape processing technology for aluminum alloy parts in the world, and is favored by more and more industries that focus on weight reduction.