Advantages of Micro-metal Injection Molding Technology

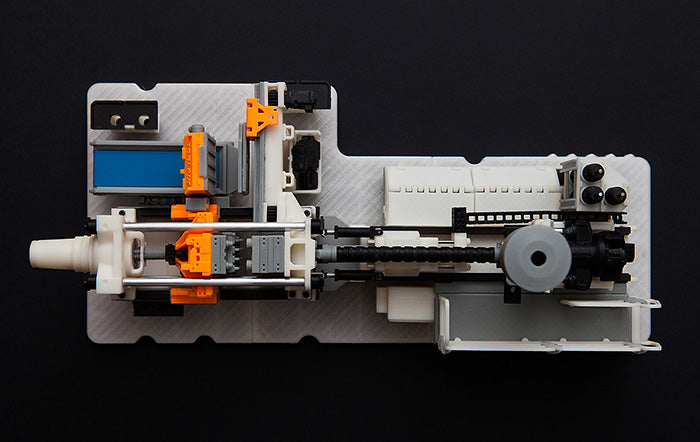

High Precision and Complex Shapes

Micro-metal injection molding technology can produce metal parts with complex structures and small sizes, which greatly meets the strict requirements of modern electronic products for component accuracy and shape.

Material Diversity

Micro-metal injection molding technology supports the application of a variety of metal materials, such as stainless steel, aluminum alloy, titanium alloy, etc., providing more options for the design of electronic products.

Save resources

Due to the high efficiency of micro-metal technology, the material and energy consumption required in the production process are significantly reduced, and micro-metal injection molding technology helps enterprises achieve sustainable development.

Improve product performance

The high strength and durability of micro-metal components help improve the overall performance and life of electronic products and enhance user experience.

Share:

Micro Metal Injection Molding for Advanced Optical Manufacturing

Applications of Tungsten Metal Injection Molding