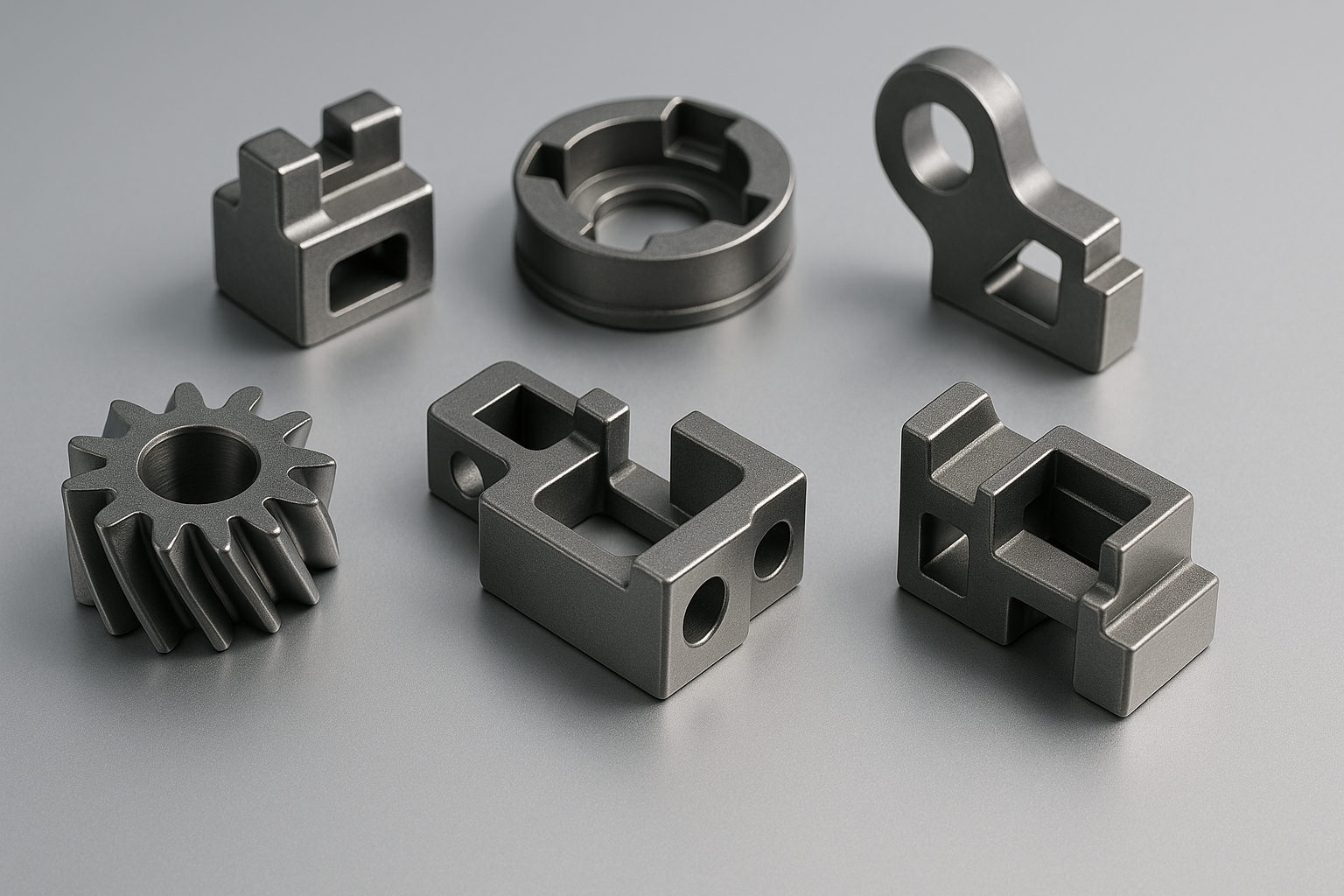

Metal Injection Moulding (MIM) is a suitable technology to fabricate small or medium-sized pieces with complex geometry. A variety of materials can be used (stainless steels, low-alloy steels, soft magnetic, tooling steel or ceramic materials). MIM combines the technique and versatility of plastic injection with sintering in order to fabricate metal pieces with high density and narrow geometric tolerances.

The following image shows the MIM process.

First steps. Fabrication of the mold: The molds employed in the MIM process are made of highly resilient steel, of complex geometry and more challenging than the molds used for plastic injection. When fabricating the hollow form, it is important to fator in the contraction of the material that will be injected, which means the hollow form has to be bigger than the actual desired piece. It is vital to stick to the design rules of the technology in this step in order to obtain a stable and immaculate product.

The number of hollow forms in the mold depends on the geometry and dimensions of the esired piece and can vary between one and ten hollow forms in total. The usual number of hollow forms lies between two and four, production time can vary between 15 and 60 seconds.

Feedstock or primary material: The primary material consists of a metal powder with a particle size of maximum 32 micrometers (at least 80% of the material must be smaller than 22 micrmeters), mixed with binders, and normally comes in the shape of pellets. The binders are made of thermoplastic, waxes, polymeres and other substances.

The characterization and control of the feedstock is crucial in order to calibrate the parameters of the following processes, especially the injection and sintering, and obtain the desired tolerances and repeatability.

Injection: Now, the feedstock is injected into the mold. The most important parameters in this step are precision, the flow volume and temperatures (of the injection head and the mold). The parameters of the injection have to be adapted to the geometry of the desired piece. The manufacturer’s know-how is vital for obtaining intact parts without internal defects. The piece obtained in this production step is called the “green part”. During the extraction from the hollow form, the material normally contracts for the first time (0.7 – 0.9% when using carbon or low-alloy steels, about 0.4% when using stainless steels).

De-binding: The binder that was necessary for the injection process now has to be removed. This de-binding can take place in several different ways: 100% thermical, water-based, with solvents or through a catalytic reaction.

The de-binding process can be carried out in vaccum batch furnaces or continuous furnaces. The advantages of using continuous furnaces are that manual handling is avoided and the brown state can be transferred directly to sintering. During this process, the piece is especially unstable and very susceptible to deformation and other damages, which makes the absence pf manual handling an important factor for the reliability of the process.

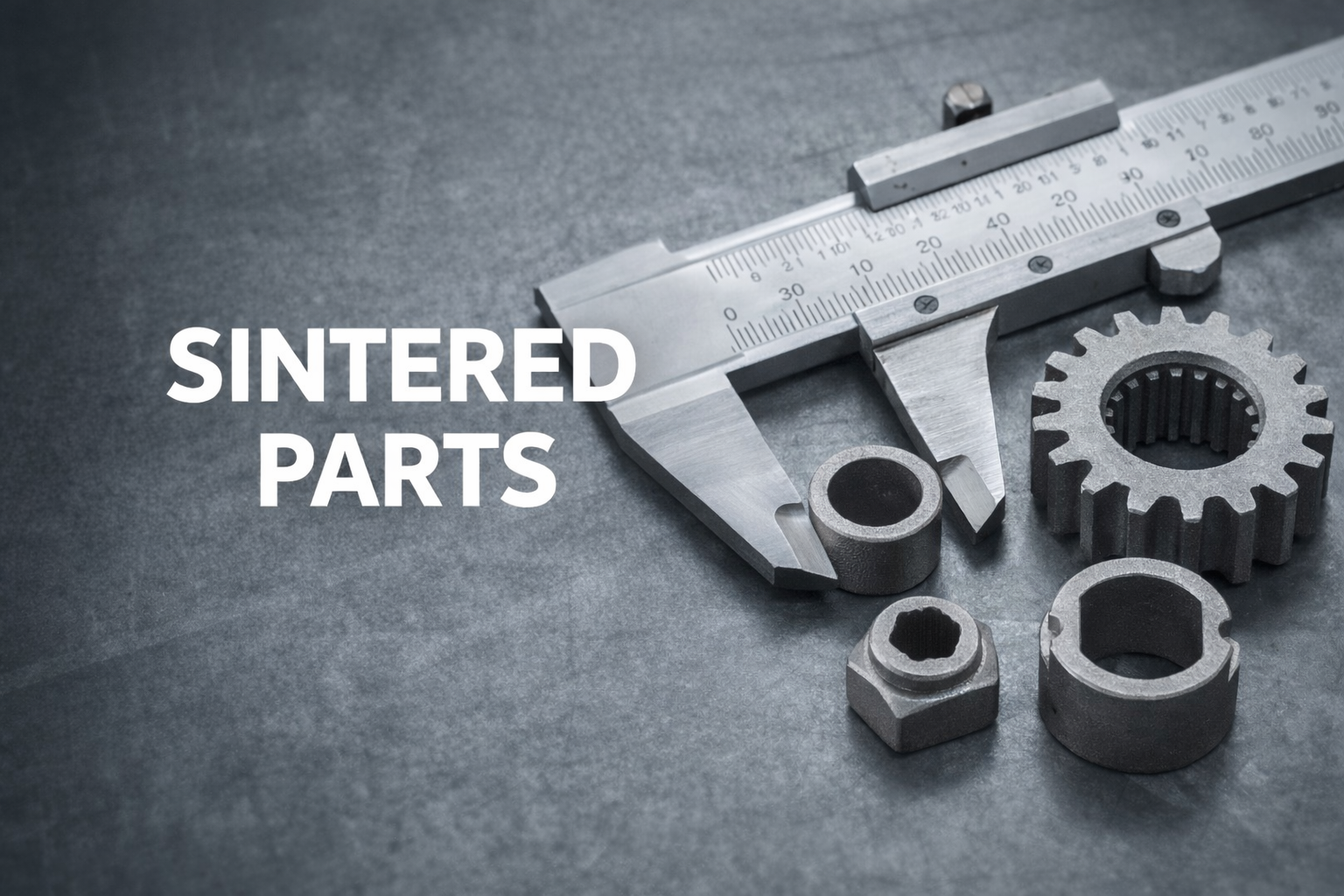

Sintering: The sintering is the last steps of the process, during which the desired density is aquired by interdiffusion of the metal particles due to thermal reactions and fase (H2 or N2, depending on the type of alloy). The pieces can be sintered in vacuum batch furnaces (especially suitable for small production volumes or special materials) or in continuous furnaces (more suitable for bigger production volumes).

Share:

Design Considerations for Metal Injection Molding

Which Is the Better Technology for Manufacturing Metal Parts, Mim or Investment Casting?