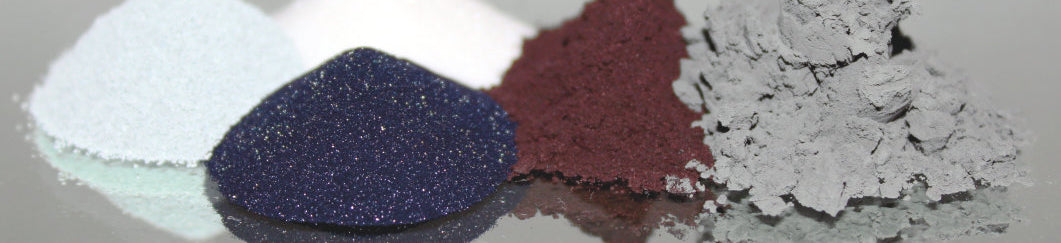

Powder metallurgy (PM) is a process technology that uses metal or non-metallic powder (or a mixture of metal powder and non-metallic powder) as raw materials, and then processes such as pressing, forming and sintering to manufacture metal materials, composite materials and various geometric structural products.

The development opportunities of the powder metallurgy industry are closely related to the automotive industry. To this day, the automotive industry is still the most concerned industry and the largest potential market for the powder metallurgy industry. Judging from the use of powder metallurgy parts in the automotive industry in developed regions around the world, the proportion of powder metallurgy parts used in the automotive industry is: about 70% in North America, about 90% in Japan, about 80% in Western Europe, and about 55% in my country. And 70% of these powder metallurgy automotive parts are used in engines and gearboxes.

In recent years, the development of new energy electric vehicles is gradually replacing traditional fuel engine vehicles. As new energy vehicles develop towards electrification and intelligence, higher requirements are placed on the comprehensive performance of materials. The powder metallurgy industry continues to develop and reserve new technologies and processes according to the industry needs of new energy electric vehicles, and with the help of lean automated manufacturing technology, it adapts to the new era requirements of energy conservation and environmental protection, and helps the development of new energy vehicles. At the same time, the development of new energy electric vehicles also provides a new opportunity for the development of the powder metallurgy industry.

Copper alloy materials

According to statistics from the International Copper Association, traditional automobile internal combustion engines use 23kg of copper, hybrid electric vehicles use 40kg of copper, plug-in hybrid electric vehicles use 60kg of copper, and electric vehicles use 83kg of copper.

Copper alloy materials refer to alloys in which one or more other elements are added to pure copper. They are characterized by excellent electrical conductivity, thermal conductivity, corrosion resistance and wear resistance, as well as high strength and fatigue resistance. Copper alloy materials can be used to make electrical components such as generators, high-voltage cables, switchgear, transformers, etc. on new energy vehicles, and can also be used to make wear-resistant and corrosion-resistant parts on automobiles such as synchronous gear rings, bearings, brake system parts, etc. With the rise of new energy vehicles, copper alloy materials will be widely used in the cooling system, electronic power system, braking system and hydraulic system of new energy vehicles as an ideal material for new energy vehicle wiring harnesses, battery accessories and connectors. They are the key basic raw materials for important components of automobiles.

Aluminum-based composite materials

Lightweight, energy saving and emission reduction... The many advantages of aluminum-based brake discs have made them successfully replace traditional iron discs and become the new favorite of the new energy vehicle industry.

Tests show that compared with cast iron brake discs, aluminum-based composite materials have good braking performance and control performance, no noise, jitter, insufficient braking force and other problems, and have obvious advantages in lightweight, improving electrical efficiency, controllability and corrosion resistance. After replacing the cast iron brake discs of new energy vehicles, the braking system alone can help reduce weight by about 15 kilograms. This means that, taking a new energy passenger car with a range of 500 kilometers as a reference, the same range can reduce the battery load by 3 kWh. Calculated based on an annual operation of 20,000 kilometers, an electric car can save about 120 degrees of electricity, which is equivalent to saving 48 kilograms of standard coal and reducing about 120 kilograms of carbon dioxide emissions. After 1 million electric vehicles are equipped with aluminum-based composite brake discs, carbon dioxide emissions can be reduced by about 120,000 tons per year. In addition, aluminum-based composite brake discs also improve battery life. It is estimated that one electric vehicle can reduce costs by about 1,000 yuan, and 100,000 electric vehicles can save about 100 million yuan in related battery costs.

Soft magnetic composite materials

Soft magnetic materials have gone through several stages of development:

From traditional soft magnetic alloys to soft magnetic ferrite materials, amorphous/nanocrystalline soft magnetic alloys were developed in the 1970s; powder metallurgy technology has spawned a new generation of high-performance soft magnetic materials, metal soft magnetic powder cores (MPC), also known as soft magnetic composite materials (SMC).

Metal soft magnetic powder cores are made of metal soft magnetic powders as raw materials, and are made into magnetic core components through insulation coating, pressing and heat treatment processes, which improves the weakness of metal soft magnetic permeability is not high enough.

SMC is a new type of magnetic material. Because of its high saturation magnetic induction intensity and low loss, it is known as the "fourth generation" soft magnetic material. It has great application advantages and broad market prospects in high-frequency motors, high-power high-frequency switching power supply transformers, high-frequency high-power energy storage inductors, etc. In electric vehicles, soft magnetic composite materials can be used for main drive motors and motors for oil pumps and cooling pumps. With the EV/green energy transformation, the demand for power transmission and control of electrical circuits has increased significantly, catalyzing the rapid iteration of demand and technical processes for soft magnetic composite materials. In addition to maintaining a high level of prosperity in traditional advantageous fields of magnetic material applications such as photovoltaic power generation and variable frequency air conditioners, soft magnetic composite materials have begun to enter a rapid growth period in incremental application fields such as electric vehicles, charging piles, and energy storage.

NdFeB permanent magnet material

The most common current new energy vehicle drive motors are permanent magnet synchronous motors and squirrel cage asynchronous induction motors in AC motors. Among them, permanent magnet synchronous motors are the most popular in China, accounting for 94% of vehicle installations.

The NdFeB magnetic material used in permanent magnet synchronous motors has excellent magnetic properties. After magnetization, it can build a strong magnetic field without adding external energy. At the same time, the magnetic field has permanent characteristics and does not require additional circuits for excitation (i.e., energizing the conductor to generate a magnetic field), so it can maintain a small volume and light weight. Under rated power, the power density of permanent magnet synchronous motors with the same heat dissipation conditions and insulation materials is usually more than twice that of induction asynchronous motors.

Carbon-ceramic composite materials

The brake materials of modern transportation vehicles such as automobiles and high-speed trains have experienced the development from asbestos materials, semi-metallic materials, powder metallurgy materials to carbon-carbon composite materials and carbon-ceramic composite materials.

Carbon-ceramic composite brake materials are a new type of composite materials developed in the 1990s, which are composed of a three-dimensional felt or braided body of carbon fiber as a reinforcing skeleton and a continuous matrix of carbon and silicon carbide ceramics. The brake pair composed of carbon-ceramic brake discs and carbon-ceramic brake pads has a promising development prospect. Under the trend of electrification and lightweight, carbon-ceramic discs can achieve weight reduction and reduce mileage anxiety. Compared with fuel vehicles, electric vehicles do not have engines and gearboxes, but they have added battery packs, which are heavier than fuel vehicles. Therefore, there is a long way to go to reduce the weight of new energy vehicles. Carbon ceramic brakes can effectively reduce the weight below the suspension system, better adapt to new energy vehicles, and reduce mileage anxiety.

With the emergence and breakthroughs of new technologies, new processes, and new energy, new application areas of powder metallurgy products will continue to emerge, and will fully support the new process of the automotive electrification era.

Share:

Application of MIM in Hinges of Foldable Mobile Phones

Advantages of Metal Powder Injection Molding Process for Manufacturing MIM Mobile Phone Accessories