Knowledge

Sintering Method and Characteristic Application of Silicon Carbide Products

Mim Metal Powder Injection Molding: Application in 3c Electronics

Which Parts Are Suitable for MIM Process?

Advantages of Metal Injection Molding(MIM)

Powder Forging Process - Important Near-Net-Shape Forming Process for Mechanical Parts

Thermal Spraying Ceramic Coating Process and Application

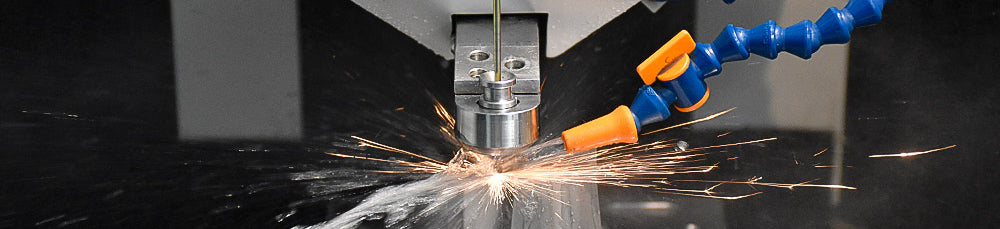

Principle and Application of Electrospark Machining (EDM)