Knowledge

We Are a Ceramic Parts Manufacturer

Materials for Powder Metallurgy - Iron Powder

Introduction to the Electrolytic Iron Powder Process

The Significance of the Promotion of Powder Forging Technology

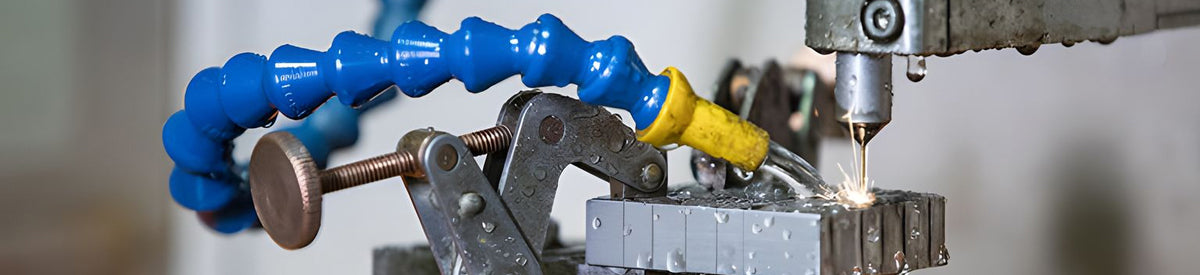

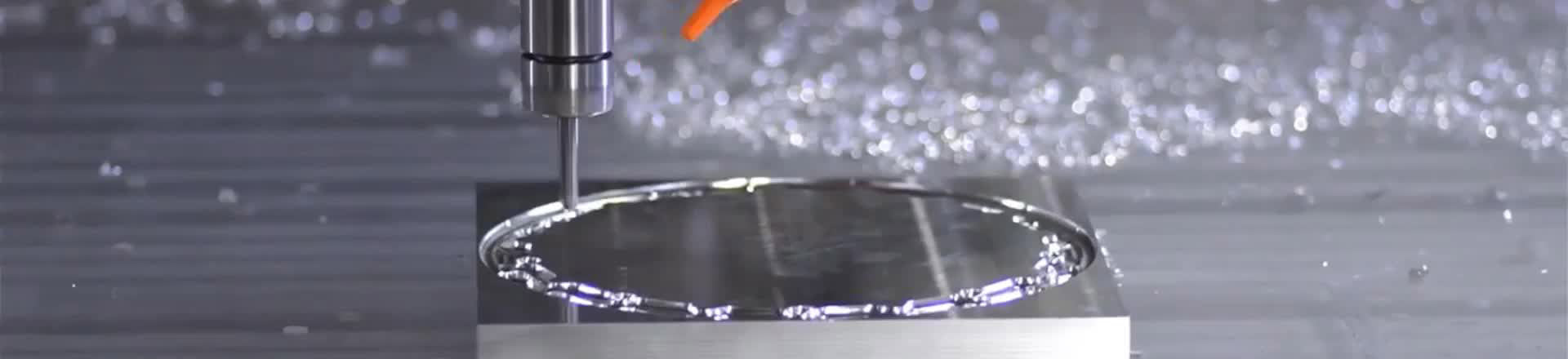

What Is the Principle of Electric Spark Processing?

Introduction to Titanium Metal Injection Molding

Precision Machining and CNC Machining in the Medical Industry

Sintering Method and Characteristic Application of Silicon Carbide Products

Mim Metal Powder Injection Molding: Application in 3c Electronics