Silicon Carbide Vacuum Pressureless Sintering Furnace

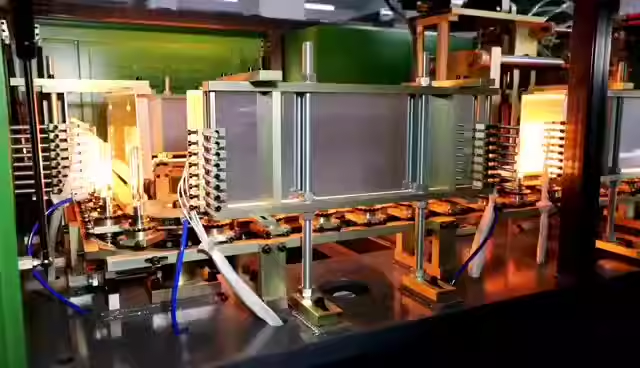

Vacuum Sintering of Electronic Devices

Considerations in Metal Injection Molding Manufacturing

Metal Injection Molding, Steering the Automotive Industry

What Are MIM’s Advantages over Other Processes

How a Medical Device Supply Chain Works

Revolutionizing MIM Processes for Motor Fan Blades

Precision Parts Processing Needs to Follow 4 Principles