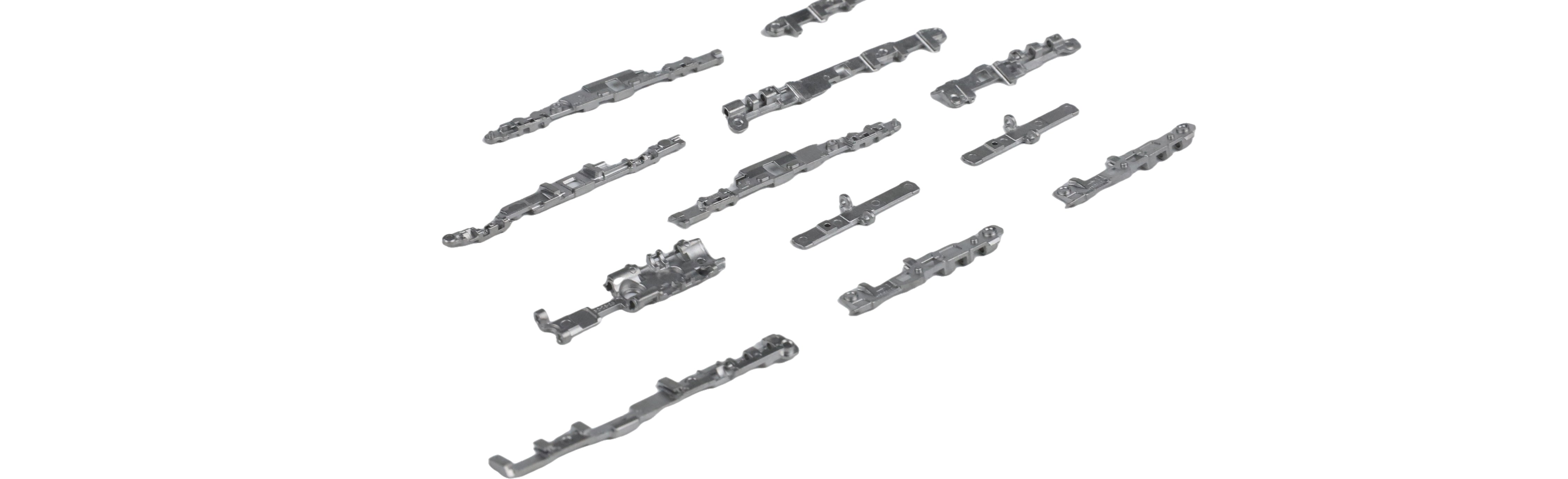

Once considered a technique only for prototyping, engineers are now realizing how metal additive manufacturing opens up new design opportunities for small engine manufacturing.

Find out below how to make complex engine parts using additive manufacturing processes and reduce cost, waste, and the number of assembly operations in the engine (and therefore the number of parts).

Benefits of metal additive manufacturing for small engines

For small engine manufacturers, metal 3D printing has many advantages, including:

1. Lower barriers to entry/time to market

2. Repair custom parts as needed

3. Sustainability

4. Combination of parts

Easy to change design

Do you have a new design for the oil pump you have been producing? With metal additive manufacturing, changing the design is as easy as jumping into a CAD program. Once your files have been changed, you can quickly process the parts and test the results.

Share:

Die Casting vs Metal Injection Molding, A Detailed Comparison

Using Metal Additive Manufacturing for Mass Production