In order to ensure the quality of precision parts, the following four principles should be followed in the processing of precision parts:

1, datum first: that is, the first processing datum surface, parts in the mechanical processing process, as the positioning datum appearance should be processed first, so as to provide precision datum for the subsequent process as soon as possible.

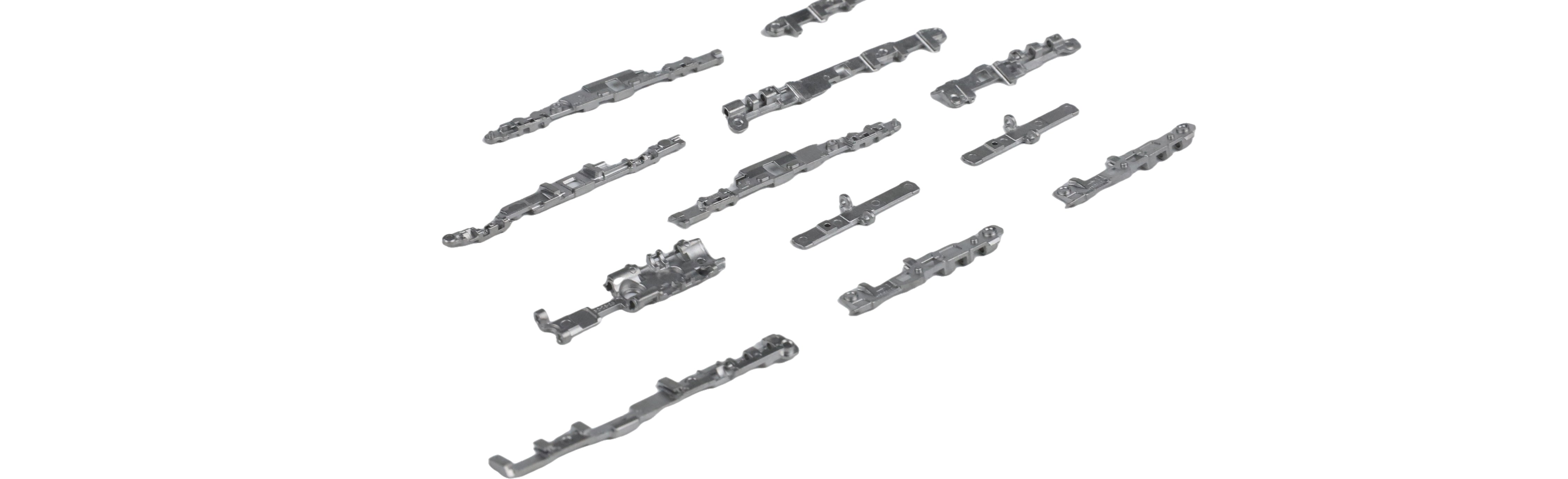

2. Divide the processing stage: the appearance of mechanical processing with high quality request is divided into the processing stage, which can be generally divided into three stages: rough machining, semi-finish machining and finish machining. Mainly in order to ensure the quality of processing; Conducive to scientific application equipment; Easy to arrange the heat treatment process; As well as facilitate the discovery of blank defects.![]()

3, the first surface after the hole: for the box body, support and connecting rod and other parts should be processed after the first plane processing hole. In this way, the plane can be positioned to process the hole, to ensure the accuracy of the plane and the hole position, but also to the plane of the hole processing to bring convenience.

4, finishing processing: the main appearance of finishing processing, such as grinding, honing, fine grinding, rolling processing, etc., should be placed in the end of the process line stage. Drawing up the general principle of precision parts processing technology route, precision parts processing technology rules can be roughly divided into two links. First of all, it is to formulate the process route of parts processing, and then determine the working procedure size of each working procedure, the equipment and process equipment and cutting specifications, man-hour quota, etc.

XY-GLOBAL has a strict process for every step of the way from production to volume production. If you have a related precision part that needs to be manufactured. Contact xy-global to have your problem solved by a dedicated engineering team and get a high quality on-demand part with expert prototyping and production capabilities. Quotations and DFM analysis can be completed online in minutes and high quality parts can be delivered within days.

Share:

High Nitrogen Steels in MIM

Revolutionizing MIM Processes for Motor Fan Blades