Mould parts of the thickness, size of the heat treatment of the impact is a very big and very dangerous thing, especially in the thickness of more than 250mm, due to heating and cooling and other reasons, there are poor hardenability, the core of the organisational transformation of the phenomenon is incomplete, do not pay attention to the control of the heat treatment process, there will be an instant crack, or there will be a certain amount of organisational stress, resulting in the use of the early cracking and other situations.

1. vacuum heat treatment process selection

Vacuum heat treatment process selection involves making careful choices based on the characteristics of the workpiece. Conventional methods, where the piece is heated to austenitization temperature using regular equipment, can lead to challenges due to complex mold shapes and thicknesses exceeding 250mm. Swift cooling disparities between surface and core, along with varying transformation rates, result in high thermal and tissue stresses. This elevates the risk of deformation and cracking.

In contrast, vacuum heat treatment at 6.0 ~ 9.5 bar entails preheating, heating to austenitizing temperature, and then air-cooling. This approach initially offers accelerated surface cooling, while gradually slowing down to avoid abrupt temperature differentials. However, prolonged cooling periods might lead to the formation of undesired structures like pearlite and bainite. These structures adversely impact mechanical properties, potentially resulting in premature cracking during use. Ultra-high pressure gas quenching above 10 bar can mimic the rapid cooling of oil quenching, yet still presents the risk of quick temperature shifts and organizational stresses.

Given this scenario, the thickness of parts exceeding 250mm requires meticulous control during vacuum heat treatment. The selection of an appropriate cooling method for vacuum quenching becomes even more crucial.

2 Vacuum heat treatment process

Vacuum heat treatment is an important method for treating metal materials, and its process generally involves the following steps:

-

Pre-treatment (Degreasing and Cleaning): Prior to vacuum heat treatment, it's essential to ensure that the surface of the workpiece is free from oils, dirt, and other impurities to avoid affecting the subsequent heating and cooling processes. Typically, degreasing and cleaning are conducted using solvents, alkaline solutions, or other cleaning methods.

-

Loading of Workpieces: Place the workpieces to be treated inside a dedicated vacuum furnace, ensuring adequate spacing between them to allow proper circulation of the heat treatment gases.

-

Evacuation of Vacuum: Create a low-pressure environment within the vacuum furnace by removing air. This helps reduce the impact of oxygen on the materials and provides a more stable environment for heating and cooling.

-

Preheating: Heat the workpieces to an appropriate temperature, usually before the material undergoes a phase change. Preheating helps alleviate internal stresses and prepares the workpieces for subsequent heating and cooling steps.

-

Heating: Raise the temperature of the workpieces to the desired treatment temperature, enabling them to achieve the desired crystalline structure state. This temperature depends on the material type and the desired performance.

-

Soaking: Once the treatment temperature is reached, the workpieces need to be held at that temperature for a certain period to ensure uniformity and stability of the crystalline structure.

-

Cooling: Following the soaking period, the workpieces' microstructure and properties can be controlled through various cooling methods. This might involve rapid gas quenching, slow cooling, or air cooling, among other techniques.

-

Vacuum Release: After the process is complete, the vacuum furnace's normal atmospheric pressure can gradually be restored, and the heat-treated workpieces can be removed.

-

Post-Treatment (Quenching, Passivation, etc.): In some cases, workpieces that have undergone vacuum heat treatment may require further post-treatment, such as quenching or passivation, to further adjust their properties and surface characteristics.

The above represents a typical vacuum heat treatment process flow, and actual procedures may be adjusted based on material types, workpiece shapes, and desired performance outcomes.

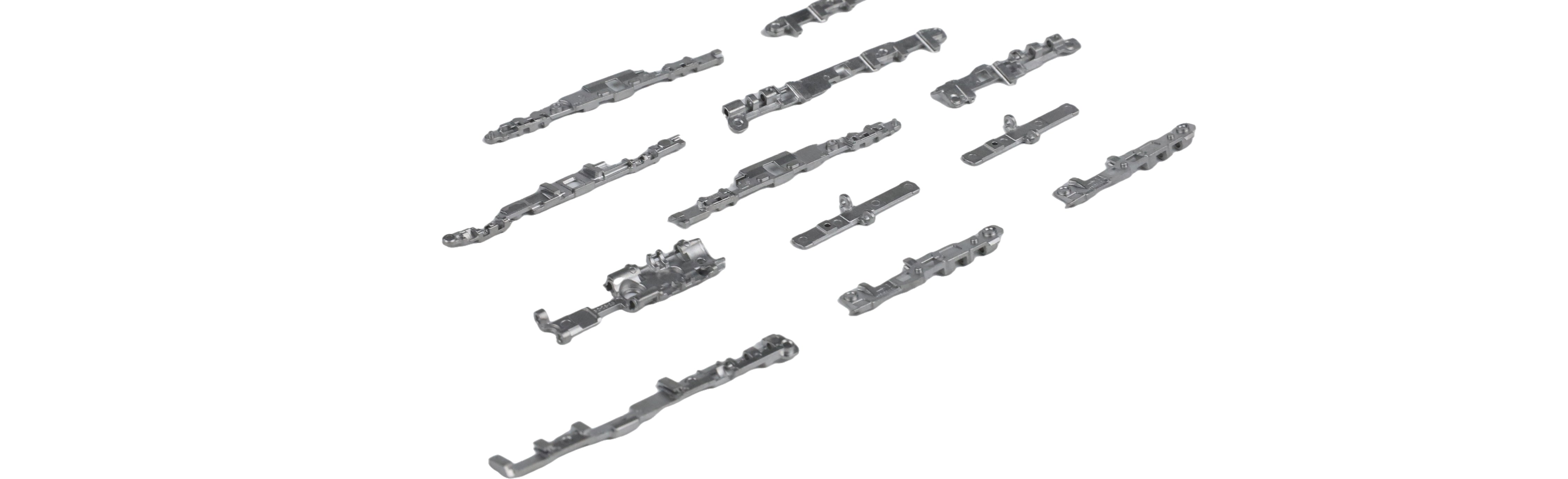

To ensure the highest standards in MIM production, the choice of heat treatment equipment is paramount. Given our focus on MIM processes, it's crucial that the selected equipment aligns with the intricacies of our production requirements.

For MIM products, precision and uniformity in heat treatment are vital to achieve the desired mechanical properties and material performance. The equipment should offer precise control over heating, soaking, and cooling stages, guaranteeing consistent metallurgical transformations and minimizing the risk of distortion, cracking, or inadequate material properties.

Vacuum Heat Treatment Equipment Selection: Achieving exceptional quality in the production of large-scale mold products demands the presence of essential performance criteria within the heat treatment equipment. Our company specializes in the manufacturing of products related to Metal Injection Molding (MIM) processes.

Share:

Specifications and Processes in Component Machining

Metal Injection Molding Has Evolved into a Sustainable and Scalable Solution for the Manufacturing of Medical Devices