Semiconductor Industry

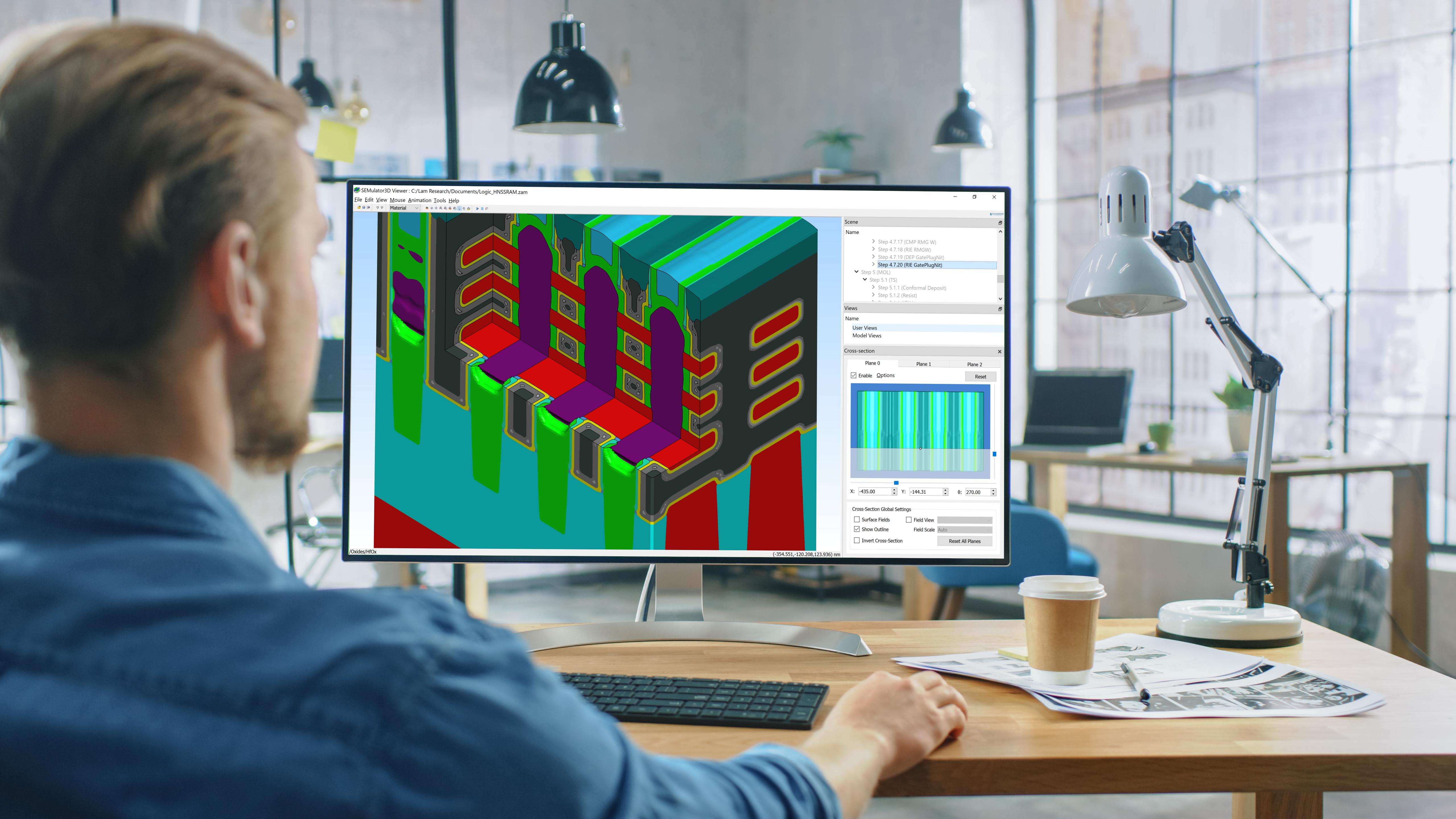

In the realm of semiconductor manufacturing, Ceramic Injection Molding (CIM) and Metal Injection Molding (MIM) have emerged as transformative technologies. These methods integrate the precision of injection molding with the unique properties of ceramics and metals, respectively, to produce components critical to modern electronics.

The parts we produce through CIM and MIM can be used in semiconductor deposition, etching, degumming and cleaning processes.

MIM Supplier's injection molded metal and ceramic products, after CNC and surface treatment, can achieve a dimensional accuracy of 0.001mm and a roughness of Ra0.01

Annual Production

Production Equipment

Machining Precision

ISO 9001:2015 Certified

XY-Global is a trusted supplier of 3C electronic components. Our ISO 9001 certification reflects our company's quality control and quality assurance system, ensuring that every product leaving the factory has been rigorously inspected and tested. We provide you with precise custom components and provide excellent service and support to ensure that you get the best products and solutions.

XY-Global is always customer-centric and committed to meeting your needs, providing high-quality electronic parts and professional services. We look forward to supporting you and helping you achieve project success!

Expert Support: Our engineers offer comprehensive support and service to solve your semiconductor manufacturing challenges.

Premium Quality: We guarantee the highest quality and traceability throughout the entire molding process, meeting semiconductor industry standards.

Full Transparency: With COAs and detailed records, we ensure complete transparency and accountability.