Optical Industry

Metal powder metallurgy is suitable for the manufacture of structural parts or auxiliary parts of optical parts, such as brackets, housings and heat dissipation components, but is not suitable for direct production of optical reflective or transmissive surfaces. For the production of optical core components, other processes (such as glass molding or precision cutting) are usually required.

Optics Related Case Studies

Rotating Camera Monitor Hinge

Low alloy nickel steel (FN08) painted using conventional MIM process.

The Rotating Camera Monitor Hinge is a specially designed hinge for camera systems, typically found in cars or other devices that require flexible monitoring. The hinge design allows the camera or monitor to rotate between different angles, providing a wider viewing angle and enhanced functionality. Combined with metal injection molding technology, the Rotating Camera Monitor Hinge can be manufactured in a high-precision, lightweight and durable manner to meet the increasingly complex design requirements of modern electronic devices.

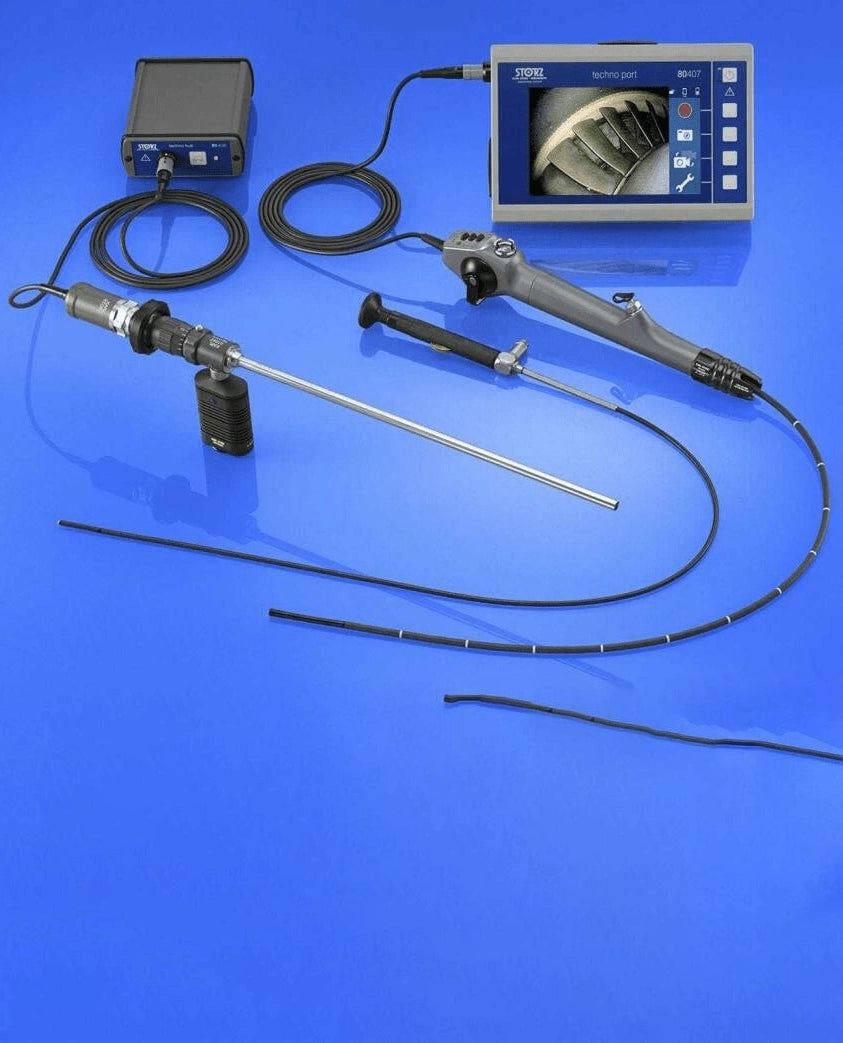

Fibroscopi & Boroscopi

Puncture System Monitoring Accessories, when made using MIM, can benefit from enhanced strength and precision. These parts, such as sensors or housings, are vital for detecting and managing puncture risks in safety-critical systems, benefiting from MIM's ability to create reliable and durable components for demanding applications.

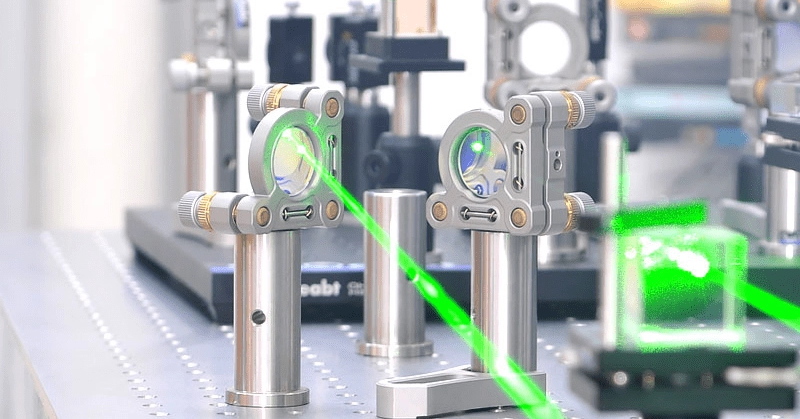

Laser Galvanometer Parts

Laser galvo parts are precision components used in laser scanning and beam control systems, and are often used in applications such as laser engraving, laser microscopy, and optical communications. Using Metal Injection Molding (MIM) to manufacture laser galvo parts offers several advantages. MIM can produce complex, high-precision metal parts with excellent mechanical properties. MIM also provides cost-effective production for high-volume production, ensuring performance and efficiency in laser galvo applications.

Optical Components

Production Equipment

Surface Finish

ISO 9001:2015 Certified

XY-Global is a trusted supplier of optical device components. Our ISO 9001 certification reflects our company's quality control and quality assurance system, ensuring that every product that leaves our factory is strictly inspected and tested. We provide you with customized components with precision and provide excellent service and support to ensure that you get the best products and solutions.

XY-Global is always customer-centric and committed to meeting your needs, providing high-quality optical components and professional services. We look forward to supporting you and helping you achieve the success of your project!

Optical Components

• Lens Barrels

• Fiber Optic Connectors

• Laser Diode Housings

• Precision Aperture Plates

• Focusing Sleeves

• Galvo Mounts

• Light Module Frames

Why Choose XY-Global to Make Optical Components

±0.02 mm

Achieve ultra-high dimensional accuracy in micro optical parts through precision MIM molding.

Ra ≤ 0.4 μm

Deliver fine surface finishes directly from sintering, minimizing post-processing for optical applications.

20+ Materials

Extensive MIM material portfolio including stainless steel, titanium, and magnetic alloys tailored for optical systems.

DFM Support

Optimize optical part performance and manufacturability with expert DFM co-engineering from prototype to scale.