Tungsten carbide coating is a widely used thermal spraying process. Tungsten carbide is a compound composed of tungsten and carbon. Tungsten carbide is insoluble in water, hydrochloric acid and sulfuric acid, but easily soluble in a mixed acid of nitric acid and hydrofluoric acid. The main differences between tungsten carbide spraying and welding are as follows:

Different heating conditions of workpieces

Tungsten carbide spraying has no remelting process, and the surface temperature of the workpiece can always be controlled below 250°C, which generally does not cause deformation and change the original structure of the workpiece. This is beneficial for spraying workpieces with complex shapes, thin walls, long sleeves and some important parts. Spraying requires melting of the powder layer, and the temperature of the remelted sintered workpiece can reach above 900°C, which is easy to cause stress and deformation, and most workpieces will undergo annealing and incomplete annealing. Different bonding states with the substrate surface The bonding of tungsten carbide spraying and the substrate surface is mainly mechanical bite, and there are also tiny microscopic welds, and the bonding strength is not high; generally 20MPa~65MPa. Welding is to form a metallurgical bond with the surface of the substrate by melting the powder layer, and the bonding strength can generally reach 343MPa~441MPa.

Different powders used

The powder used for spray melting must be a self-fluxing alloy powder, while the powder used for tungsten carbide spraying is not restricted.

Different spray layer structure

The spray melting layer is uniform and dense, and it is generally believed to be free of pores, while the tungsten carbide spray layer has certain pores.

Different load bearing performance

Tungsten carbide spray layer cannot withstand impact loads and high contact stresses, and is suitable for various surface contact fits. The spray melting layer has a high bonding strength, can withstand impact loads, can be used in line contact and other occasions, and can withstand high contact stresses.

Share:

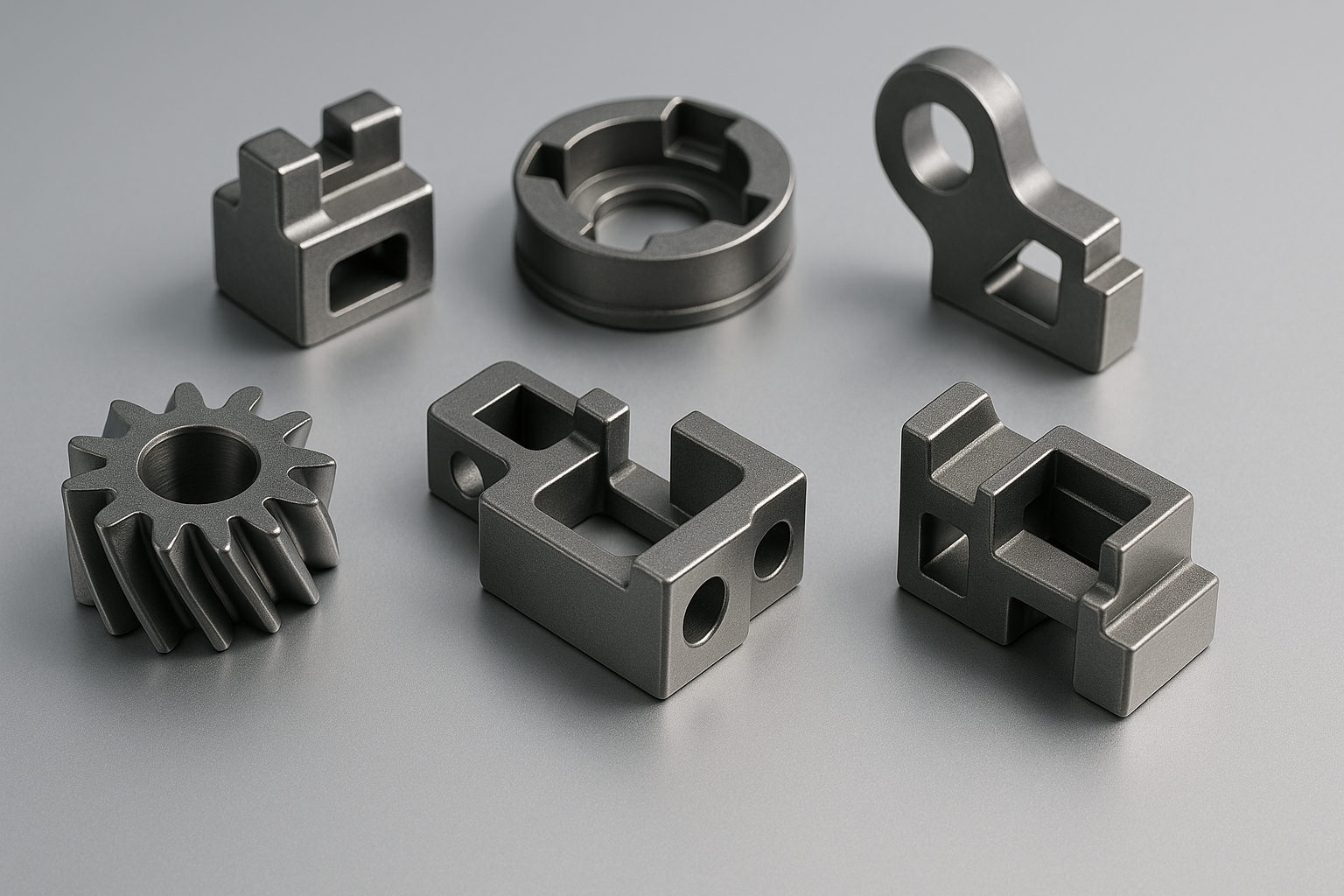

Iron-Based Alloys of Metal Powder Injection Molding Materials

What Alloy Materials Are Needed for Aerospace Engines?