XY is committed to product research and development, construction and maintenance services.

Our company has a long history. We have advanced equipment, a young, energetic, proficient and experienced professional team, leading technical strength, excellent operation management and high-quality services make us recognized by customers in the chemical, petroleum, power, metallurgy, building materials, aerospace, machinery and other industries.

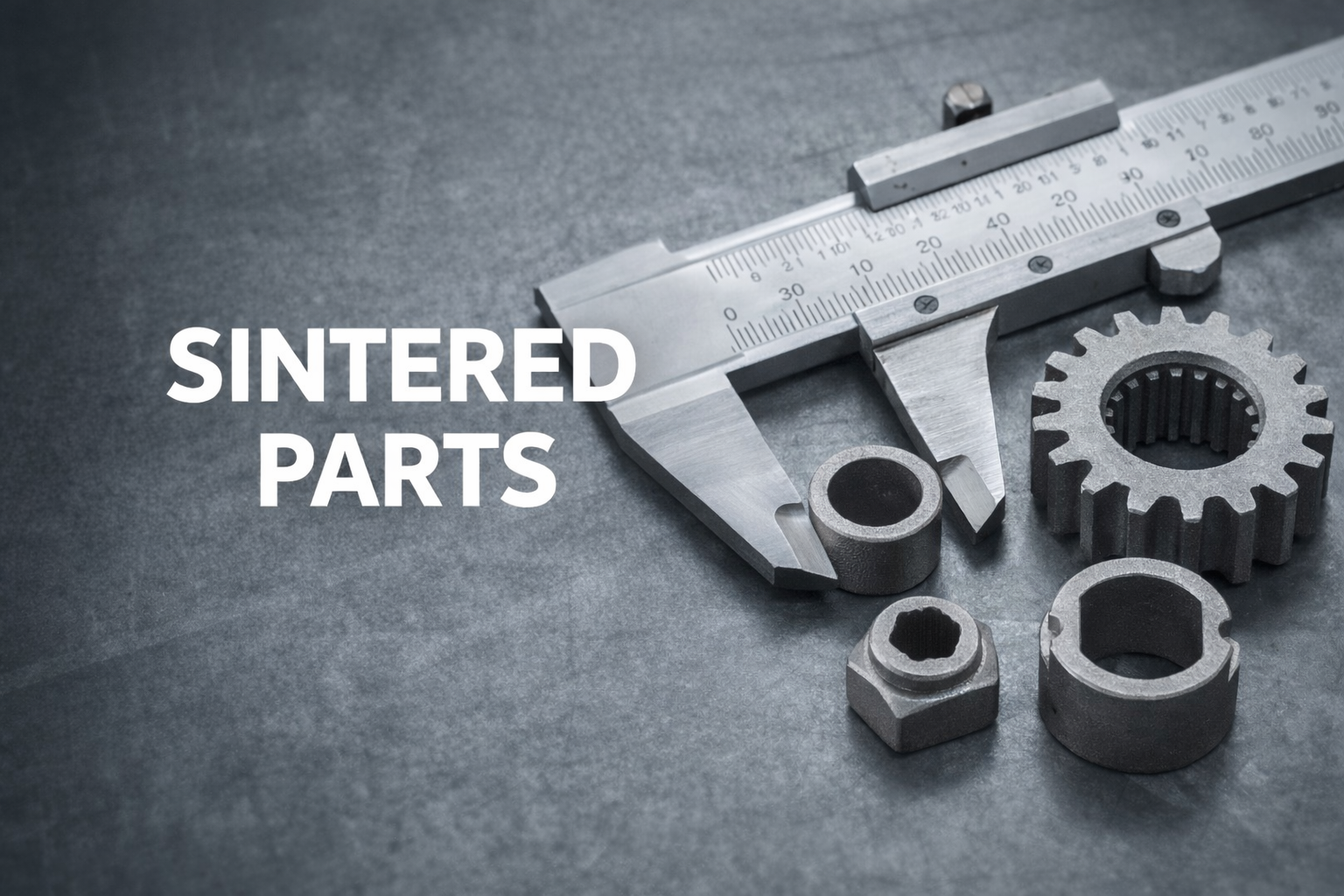

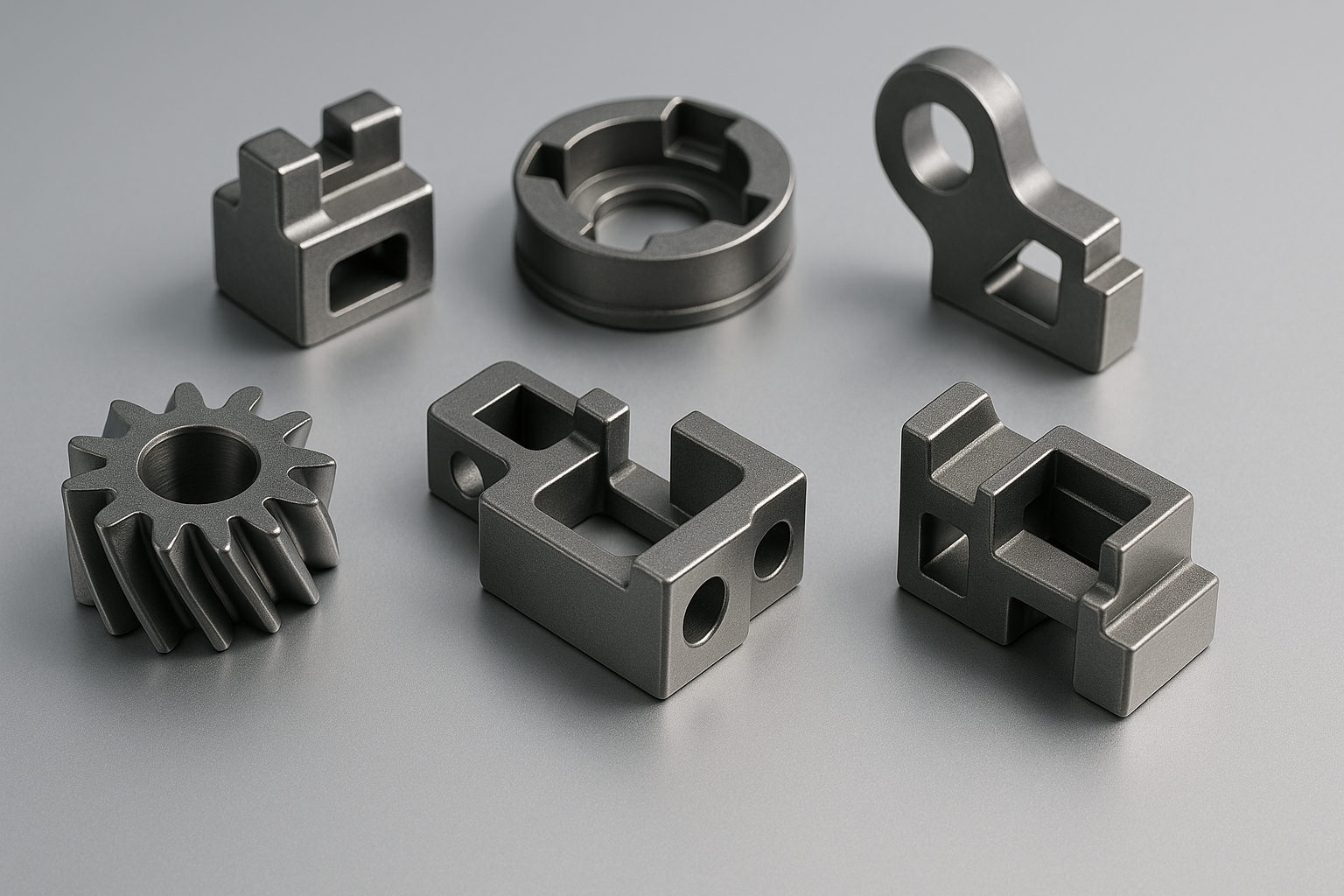

Our ceramic parts:

(1) High density, good chemical resistance

(2) Good temperature resistance: long-term use at 1600 ° C, short-term use at 1800 ° C

(3), good resistance to rapid cooling and rapid heating, not easy to burst.

(4) Slip casting and high density

(5) Customized in various shapes and sizes.

(6) Will provide professional, environmentally friendly, convenient and efficient packaging services

Why us?

* Professional manufacturer.

* Strict quality control of production process and tolerances

* Free technical support and lifetime quality guarantee

* Customized production according to your drawings or specifications

* On-time delivery and reliable support and service

* Stock available for quick shipment

* We keep all drawings and business information confidential between us.

What can we do for you?

1. Free samples.

2. Independent research and development, ISO manufacturing, precise quality standards, modern logistics management, sound marketing strategy.

3. Inquiries are replied within 24 hours.

4. Patented products.

5. OEM or ODM can be provided.

6. Some additional accessories can be provided.

7. The larger the quantity you order, the more competitive the price you will get.

8. Necessary certificates can be provided.

Share:

Materials for Powder Metallurgy - Iron Powder

Application of Ceramic Parts in New Energy Vehicles