Injection molding is a common manufacturing process that can be used to produce a variety of complex parts.

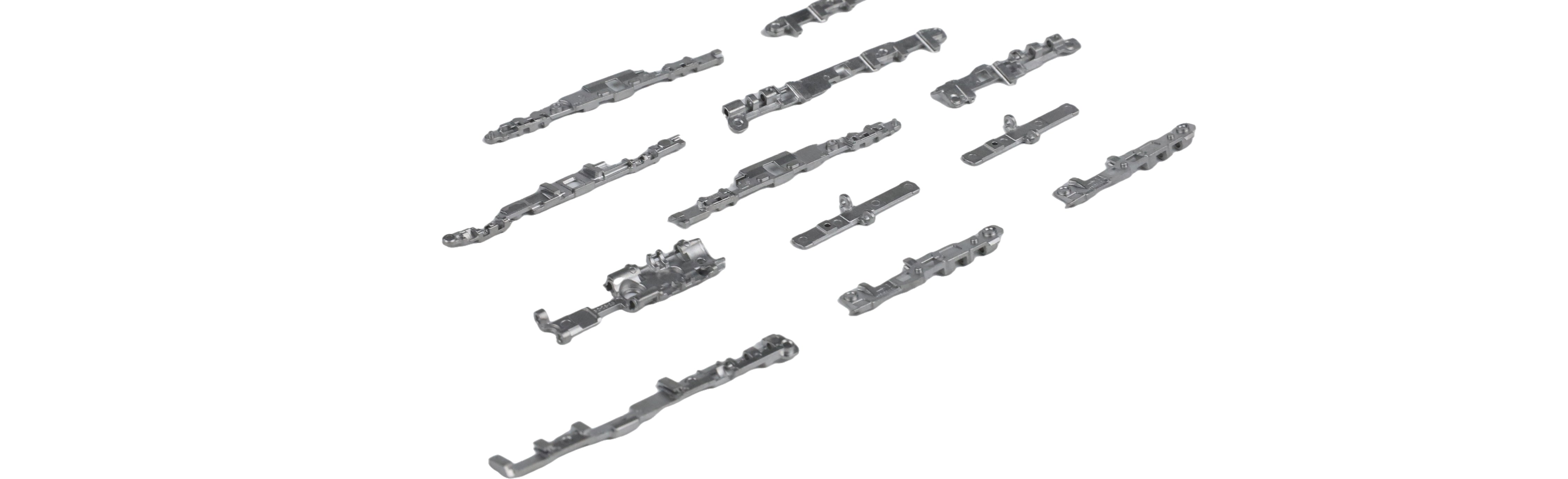

And aluminum parts are a common choice in injection molding.

The following is a look at the issues related to injection molded aluminum parts from several perspectives.

1. Advantages of injection molded aluminum parts

Compared to traditional aluminum part processing, injection molding has the advantage of being able to produce parts with more complex shapes. In addition, injection molding is a simple process with high productivity and the ability to produce a large number of parts in a relatively short period of time, thus reducing costs. In addition, aluminum material itself has the characteristics of light weight, high strength and good thermal conductivity, so injection molded aluminum parts have better mechanical properties and excellent thermal conductivity, which are suitable for applications in automotive and electronic equipment.

2. Manufacturing process of injection molded aluminum parts

The manufacturing process of injection molded aluminum parts generally includes the following steps: first, the injection mold is designed and made; then, the aluminum alloy material is heated and pressure treated to form a liquid state; then, the liquid aluminum alloy is injected into the injection mold, and after cooling and curing, the desired aluminum parts are finally obtained. It is worth noting that the melting point of aluminum alloy is low, so it is necessary to control the parameters of temperature and pressure during the injection molding process to ensure the quality of the parts.

3. Application areas of injection molded aluminum parts

Due to its good mechanical properties and thermal conductivity, injection molded aluminum parts are widely used in the fields of automobile, electronic equipment, communication equipment and aerospace. For example, automotive engine heads, electronic equipment housings and other parts can be molded using injection molding aluminum technology to achieve better performance and higher production efficiency.

4. Quality control of injection molded aluminum parts

In the injection molding process, strict quality control is required because several factors are involved. The main control factors include the design and production of injection molds, the quality and performance of materials, and the control of injection molding process parameters. Regular inspection and maintenance of injection molds, injection machines and materials are required during the production process to ensure that the aluminum parts produced meet the customer's requirements, and a series of measures need to be taken during the manufacturing process.

First, in the design stage of aluminum parts, the characteristics of the material and the limitations of the manufacturing process need to be taken into account to ensure that the design is reasonable and the manufacturing is feasible.

Second, in the process of machining aluminum parts, high-precision machining equipment and processes need to be used to ensure processing quality and precision.

In addition, proper cooling and lubrication measures need to be used during the machining process to avoid deformation of the aluminum and damage to the surface quality.

In order to ensure the quality of aluminum parts, strict quality inspection of the machined aluminum parts is also required. Common inspection methods include coordinate measurement, optical measurement, metallographic inspection, etc. Through these inspection means, the dimensional accuracy, surface quality and material organization of aluminum parts can be ensured to meet the requirements.

In addition to strengthening quality control and quality inspection in the manufacturing process, other measures can be used to ensure the quality of aluminum parts. For example, rigorous screening and testing of raw materials can be conducted to ensure that the quality of the materials meets the requirements. In addition , methods to improve processes and process parameters can also be used to increase production efficiency and reduce the rate of non-conforming products.

Overall, ensuring that the aluminum parts produced meet customer requirements requires a number of aspects, including design, processing, and quality control, and requires a series of measures to strengthen quality management. Only in this way can we produce high-quality aluminum parts to meet customer needs and take an advantageous position in the market competition.

XY-GLOBAL has a rigorous process in place for every step from production to volume manufacturing. If you need custom injection molded aluminum parts, contact xy-global for a dedicated engineering team to solve your problem and get high quality on-demand parts with professional prototyping and production capabilities. Our quotes and DFM analysis can be completed online in minutes, and high quality parts can be delivered in days.

Share:

Exploring Metal Injection Molding and Ceramic Injection Molding

Relevance and Considerations for Plastic Injection Molding of Metal Inserts