Ceramic Injection Molding

Scale Your Innovation, from Design to Delivery

Ceramic Injection Molding (CIM)

Ceramic Injection Molding (CIM) is an efficient, near-net-shape manufacturing technology designed to efficiently mass-produce precision ceramic parts with complex geometries. By combining the design freedom of injection molding with resilient ceramic materials, CIM which is similar to Metal Injection Molding (MIM) ensures efficiency and repeatability through five critical stages: mixing, injection molding, debinding, sintering, and final post-processing. In many cases, CIM can also be combined with ceramic machining to achieve tighter tolerances and finer surface finishes for specialized applications.

At XY-GLOBAL, our CIM production capability unites unparalleled design freedom with industrialized scalability. We strictly control every step of the process to ensure cost-effective, high-precision advanced ceramic manufacturing solutions, committed to delivering custom molded ceramic parts and expertise to clients worldwide.

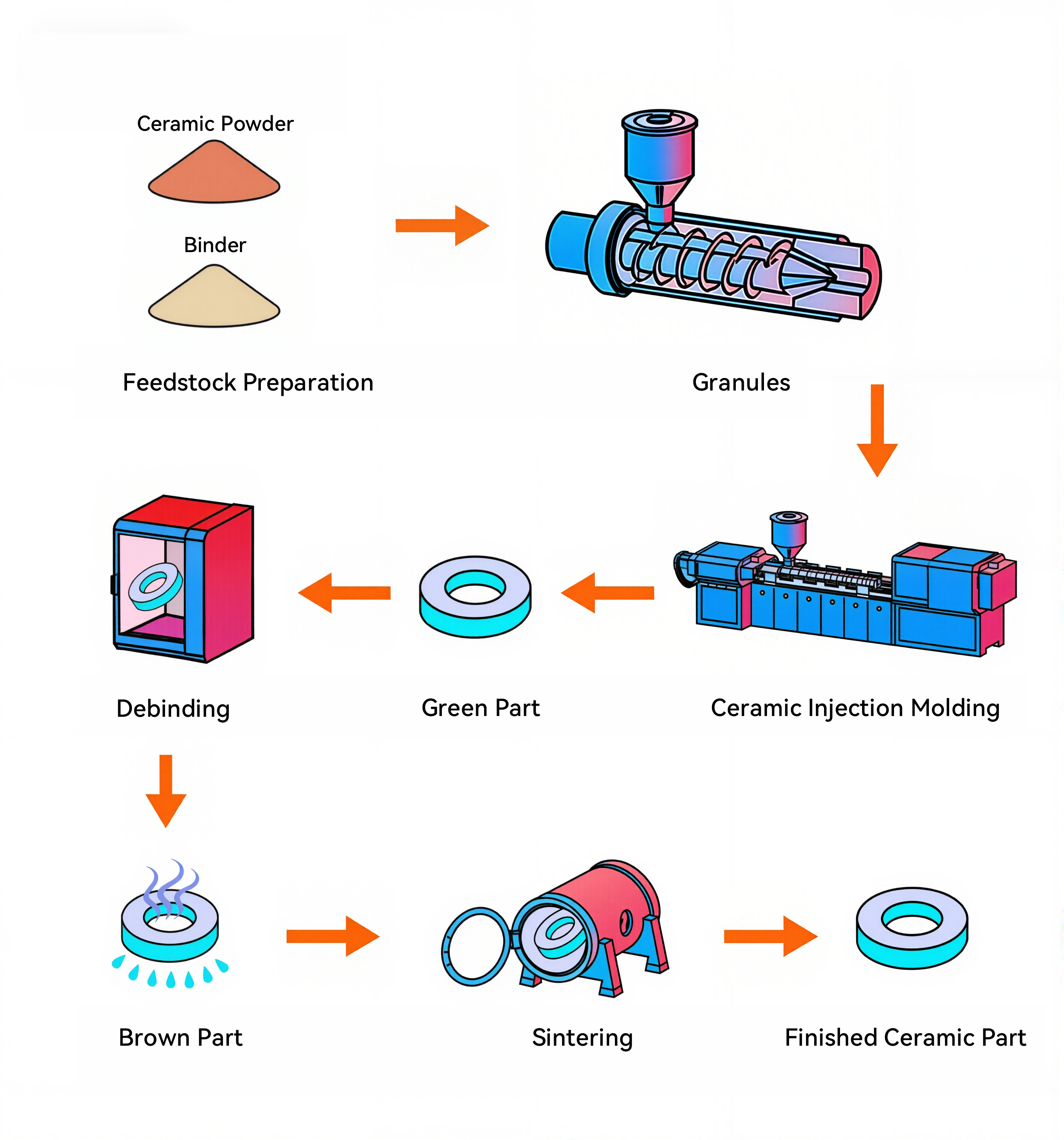

Ceramic Injection Molding(CIM) Process

1. Feedstock Preparation

Ultra-fine ceramic powders are precisely mixed and compounded with polymer binders to create a high-viscosity "feedstock." We specialize in compounding advanced ceramic materials such as Alumina, Y-TZP, and Silicon Nitride to ensure a perfectly homogenized feedstock.

2. Injection Molding

The plasticized feedstock is injected under high pressure into a custom mold cavity, forming the “green part” with the required complex geometry. We utilize ARBURG all-electric injection molding machines to achieve the one-step forming of components with complex geometries and uniform wall thickness down to 100μm.

3. Debinding

The resulting “green part” undergoes a carefully controlled thermal or chemical process to gently extract the temporary polymer binder, leaving behind a porous yet structurally sound “brown part.” Our meticulous process control minimizes the risk of internal defects and cracking during binder removal.

4. Sintering

The "brown part" is heated to extreme temperatures for full densification in advanced vacuum or atmosphere-controlled sintering systems. We guarantee custom parts with a tight tolerance of 1μm and a density exceeding 99.5%.

Ceramic Injection Molding (CIM) Process

FeedStock

The first step of the CIM process is to mix the ceramic powder with a binder to form a uniform raw material (the most commonly used material is zirconium oxide). The raw material needs to have good fluidity for subsequent injection molding. The precise control of this step directly affects the uniformity and performance of the final product.

Molding

The mixed ceramic powder metallurgy raw materials are injected into the mold to form the initial component, called the "green body". The green body is usually slightly larger than the final product to compensate for the inevitable shrinkage during the sintering process. Injection molding can efficiently produce parts with complex geometries, which is one of the core advantages of ceramic powder metallurgy technology.

Debinding

After molding, the plastic blank needs to be degreased to remove most of the binder in the raw material. This process produces an intermediate product called a "brown part". The brown part has the basic shape, but has lower strength and requires further processing to achieve final properties.

Sintering

Sintering is a key step in the ceramic powder metallurgy process. By heating the blank to a temperature close to the melting point of the metal, the residual binder is removed and the material is densified. The sintered parts are close to the final size and have the required physical properties and mechanical strength. This process determines the final density and geometric accuracy of the product.

Annual Parts Production

Custom Projects Completed

On-Time Delivery Rate

Core Advantages of CIM Tech

High Precision and Consistency

The dimensional tolerance of parts strictly controlled within ±0.1%~±0.3%, with low surface roughness (Ra≤0.8μm) and excellent consistency between parts.

High Volume Production

Suitable for producing large numbers of parts quickly and efficiently with superior propertities and durability.

Reduced Waste and Controllable Cost

A material utilization rate exceeding 95% to further save man-hours and costs.

Complex Geometries

Ability to create parts with complex shapes that are difficult or impossible to create using traditional methods.

Ceramic Injection Molding Materials

While CIM is theoretically adaptable to most ceramic powders, we focus our expertise on high-performance materials. We mainly specialize in Alumina, Zirconia, Zirconia Toughened Alumina (ZTA), to meet stringent performance requirements.

Alumina

Extreme hardness and superior electrical insulation, making it the primary choice for components requiring thermal stability and chemical resistance in high-wear environments.

Zirconia

Outstanding fracture toughness and high biocompatibility, ideal for structural parts, medical implants, and applications where exceptional resilience and wear resistance are mandatory.

Zirconia Toughened Alumina (ZTA)

A robust composite that merges the hardness of Alumina with the toughness of Zirconia, uniquely suited for high-stress and high-impact applications requiring maximized durability.

Ceramic Injection Molding(CIM) Applications

Ceramics are extensively used across high-tech industries, ranging from aerospace, healthcare, robotics, optics, precision electronics, and automotive to new energy and the semiconductor industry, thanks to their exceptional, multi-functional properties. XY-GLOBAL is your specialist partner, delivering custom-molded ceramic parts precisely engineered to meet the stringent performance and dimensional requirements of your demanding global applications.

- Resistance to High Temperatures

- Wear and corrosion Resistance

- Chemical Inertness

- Electrical Insulation

- High Hardness

- Lightweight Nature

- Biocompatibility

Healthcare

The medical field benefits from the many properties of ceramics, such as inertness, non-toxicity, hardness, high compressive strength, low friction coefficient, wear and chemical resistance, sterility, the ability to fabricate various degrees of porosity, excellent aesthetics, and durability.

- Artificial Joints

- Dental Implants

- Fine Surgical Tools

Optics

The optical sector leverages ceramics for properties such as excellent dimensional stability, low thermal expansion (CTE), high stiffness, chemical inertness, and superior rigidity ensure dimensional stability and zero deformation under temperature fluctuations.

- High-Stiffness Fixtures and Jigs

- Optic Ferrules and Sleeves

- Precision Support Components

- Sensor Probe Housings

Semiconductor

Advanced ceramics are essential in semiconductor manufacturing, because of their ultra-high purity, superior plasma resistance, and robust dielectric properties. These features safeguard sensitive wafers from contamination and endure the corrosive, high-energy conditions within plasma etching chambers. CIM technology ensures the precise fabrication of the complex, high-purity components needed for all front-end processing.

- Wafer Chucks and Holders

- Process Gas Injectors and Nozzles

- End Effectors and Robot Arms

- Insulators for High-Voltage Applications

Telecommunication

Thanks to ceramic components' low dielectric loss, high thermal conductivity, superior high-frequency stability, ultra-high precision in micro-structures, chemical inertness, and exceptional durability, the communications industry is able to achieve unprecedented levels of performance, efficiency, and reliability in modern network infrastructure.

- 5G/6G Massive MIMO Components

- High Power RF Heat Dissipators

- High-Frequency Ceramic Filters & Resonators

Electronics

Technical ceramic products have now become proven components, along with electronic technology components, in the construction and control of complex plants, machinery, and equipment. Advanced materials offer a wide range of electrical conductivity and good magnetic properties, and they can often achieve smaller dimensions compared to metallic materials.

- Heat Sinks

- Microelectronic Component Packages

- Sensors

Why Choose XY-Global for Ceramic Injection Molding?

Ultra-Precision Tolerances: Flatness is controlled down to 0.002 mm, with surface roughness reaching Ra 0.2μm. Internal bore roughness is achieved as fine as Ra 0.02μm, and hole tolerances are maintained within 0.005 mm.

Versatile Material Options: Choose from a broad range of ceramic materials to suit specific application needs for custom-made ceramic products.

Maximized Cost Efficiency: Enable large-scale manufacturing to significantly reduce your production time and overall unit cost.

15+ Years of Expertise: Bring deep knowledge and proven success in delivering complex, high-performance ceramics.

Dedicated Customer Service: Provide attentive, personalized support from our expert team to address all your requirements promptly.

Certified Quality & Advanced Equipment: Validated by ISO 9001 and ISO 13485 certifications and equipped with advanced metrology equipment like three-dimensional ZZS machines to ensure optimal user experience.

Have we sparked your interest? Partner with us today—share your project details, and let’s engineer the perfect solution for you.

Ceramic Injection Molding FAQ's

What is Ceramic Injection Molding (CIM)?

CIM is a manufacturing process that combines the versatility of plastic injection molding with the durability and performance of ceramic materials. It is used to produce small, complex, high-precision ceramic parts in large quantities.

What Materials Are Used in CIM?

- Alumina (Al₂O₃): Excellent hardness and wear resistance.

- Zirconia (ZrO₂): High strength, toughness, and thermal stability.

- Silicon Nitride (Si₃N₄): Exceptional mechanical properties and resistance to high temperatures.

- Aluminum Nitride (AlN): Superior thermal conductivity and electrical insulation.

What Industries Use CIM Components?

- Medical: Ceramic machining enables the production of surgical tools, implants, and dental components with high precision and durability.

- Semiconductor: Insulators, fixtures, and precision housings are often manufactured using ceramic machining to ensure excellent electrical insulation and stability.

- Optical: Lenses, precision brackets, and housings for optical systems benefit from ceramic machining to achieve complex geometries and fine surface finishes.

- Automotive: Ceramic machining supports the development of sensors, fuel injectors, and wear-resistant components that require both reliability and long service life.

- Consumer Electronics: Wearable device parts, optical components, and casings are commonly produced with ceramic machining to meet miniaturization and design flexibility needs.

What Tolerances Can CIM Achieve?

TOL ±1µm, Ra≤0.01

How Do Ceramic Parts Manufacturers Ensure Precision and Reliability?

Ceramic parts manufacturers ensure precision and reliability through advanced machining processes like CNC grinding, ultrasonic machining, and hot isostatic pressing. They also carry out dimensional inspection, surface finishing, and 3D measurement to maintain strict quality standards.

How Do I Start Using CIM in My Project?

Work with CIM manufacturers to assess feasibility, select materials, and design tooling. The prototype phase validates the design before moving to mass production.