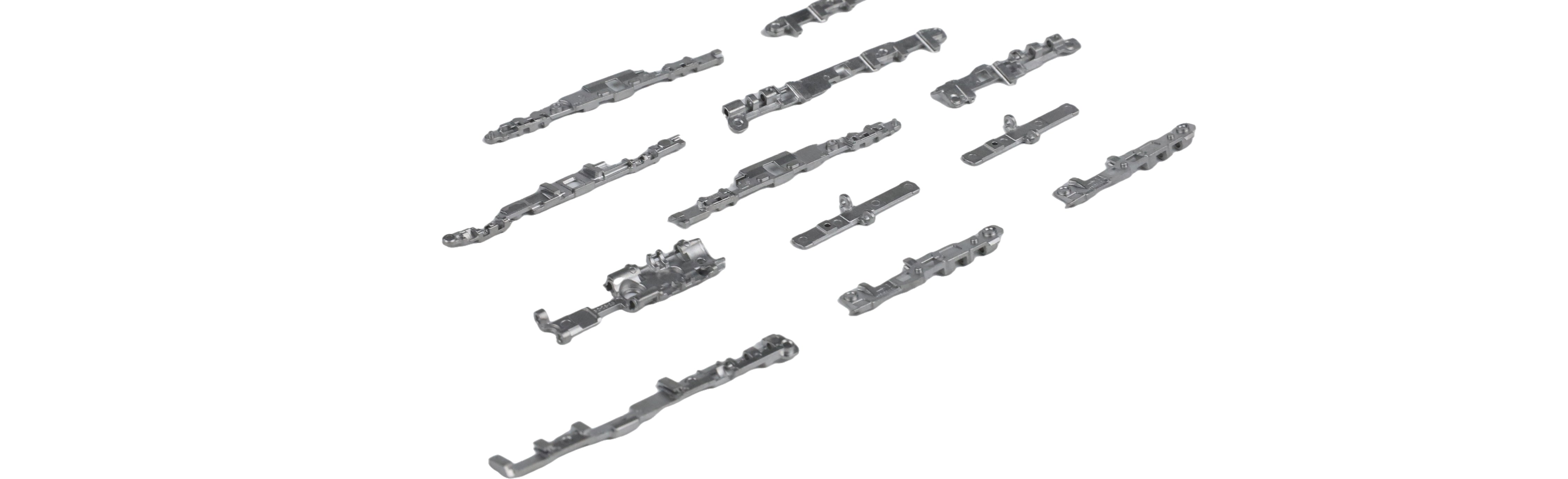

Metal Injection Molding (MIM) is a manufacturing process that combines the versatility of plastic injection molding with the strength and integrity of metallic materials. It involves the production of small, complex metal parts through a series of steps, including powder blending, injection molding, debinding, and sintering.

MIM Injection Molding is essentially the same as Metal Injection Molding (MIM), which refers to the process of injecting metal powders into molds to create intricate metal parts. The term "MIM Injection Molding" might be used to emphasize the injection molding aspect of the process.

"MIM Casting" could refer to a casting process that utilizes metal injection molding techniques, although it's less common. Typically, MIM involves powder injection into molds followed by sintering, rather than a traditional casting process. However, there might be variations or hybrid methods that incorporate elements of both MIM and casting techniques.

Metal Injection Molding (MIM) offers several advantages:

-

Complex Geometry: MIM allows for the production of intricate and complex shapes that are difficult or impossible to achieve with traditional manufacturing methods. This includes features such as undercuts, internal cavities, and fine details.

-

High Precision: MIM produces parts with tight tolerances and excellent dimensional accuracy, often eliminating the need for secondary machining operations.

-

Material Versatility: MIM can utilize a wide range of metal powders, including stainless steel, titanium, copper, and more. This versatility allows for the production of parts with various mechanical, thermal, and magnetic properties.

-

High Strength: MIM parts exhibit high strength and density comparable to wrought materials, making them suitable for demanding applications.

-

Cost-Effectiveness: Despite the initial tooling costs, MIM can be cost-effective for high-volume production due to its ability to produce complex parts in large quantities with minimal labor.

-

Reduced Waste: MIM generates minimal material waste compared to traditional machining processes, as it typically utilizes nearly all of the injected powder.

-

Design Flexibility: MIM offers designers the freedom to create innovative and optimized designs without being limited by the constraints of traditional manufacturing methods.

-

Surface Finish: MIM parts can achieve excellent surface finishes, reducing or eliminating the need for post-processing operations such as polishing or coating.

Overall, Metal Injection Molding provides a highly efficient and versatile manufacturing solution for producing complex metal parts with high precision and performance.

Share:

Metal Injection Molding VS Die Casting

Comparison of Wet Bag Isostatic Pressing and Dry Bag Isostatic Pressing