Micro metal injection molding can manufacture precise and complex small devices in the medical device industry, such as micro surgical tools, implants and sensors. These products not only require high precision, but also must meet strict hygiene standards, and μMIM performs better in this regard.

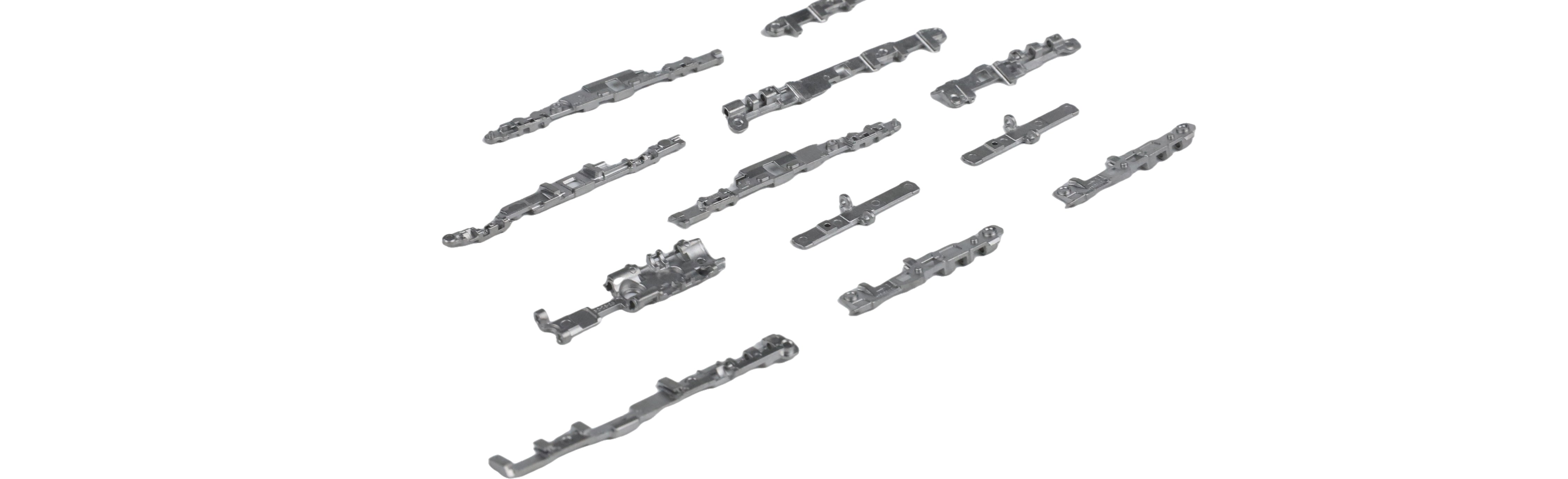

MIM parts in medical devices including: orthodontic brackets, surgical instruments, forceps, scissors, sewing units, drug delivery devices, surgical implants, hearing aids, dental equipment & implants, B-ultrasonic instrument parts.

MIM parts are becoming more cost-effective than traditional investment casting, such as orthodontic device manufacturing process. We can produce this device by stainless steel with high strength, smooth and precision.

Share:

What is Metal Injection Molding Powder?

Micro Metal Injection Molding for Electronic Products