Antibacterial Stainless Steel

Ag > Hg > Cu > Cd > Cr >P b > Co > Au > Zn > Fe > Mn > Mo > Sn

Advantages:

● In all metals, silver antibacterial ability is strongest, about 100 times of copper.

● Have more broad antibacterial spectrum, can kill more types of pathogenic bacteria.

● Add less than one over ten of copper, stainless steel has a little influence on the performance of the original level.

● Silver and iron is immiscible element of a typical system, almost no solubility in liquid or solid state

● Existing casting process is easy to produce silver element segregation, the improvement of heat treatment process is very limited

● Antibacterial performance is not stable, the high energy consumption of the heat treatment process, the effect is not obvious, it is difficult to use in the industrial production

● Through the silver compound is added to the raw materials, the compound decomposition in the process of sintering formed dispersed silver particles

● Excellent antibacterial properties, antibacterial above 99%

● Stable antibacterial ability, silver particle dispersed evenly

● Have permanent antibacterial ability, does not fear the scrapes and cuts

Powder metallurgy silver bearing 316L stainless steel (left)

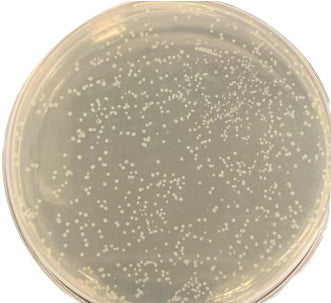

Past silver bearing antibacterial test results of 316L stainless steel (middle)

Silver containing stainless steel (right)

Antibacterial test results

The Ag - Fe phase diagram shows that Ag - Fe is insoluble in solid state and does not form intermetallic compounds

● Use of powder injection molding, can't solve the silver iron miscibility engineering problem

● The nanosize silver particles were distributed evenly in the stainless steel substrate, produce good antibacterial performance

● Only add trace silver, will not affect the performance of stainless steel, not significantly increase the cost of stainless steel

● Can manufacture different type of antibacterial stainless steel

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays and weekends.

Customer Support

Your satisfaction is our priority.

We offer comprehensive Lifetime Technical Support and Warranty Services.

Contact Us

WhatsApp: +86 180 0255 3024

Email: market@mim-supplier.com

Shipping Information

We usually send samples to you via DHL FedEx or UPS.

Bulk goods will be shipped by sea to save shipping costs

FAQ’s

What materials do you provide?

We offer a wide range of materials for powder metallurgy.

MIM: 304 316 420 17-4 Stainless Steel, TC4 TA2 Titanium Alloys, AISI 310S Nickel-Chromium-Iron Alloys

CIM Process: Zirconia, Alumina, Silicon Nitride, Silicon Carbide, and Aluminum Nitride

Our R&D team can develop customized materials to meet your specific application requirements.