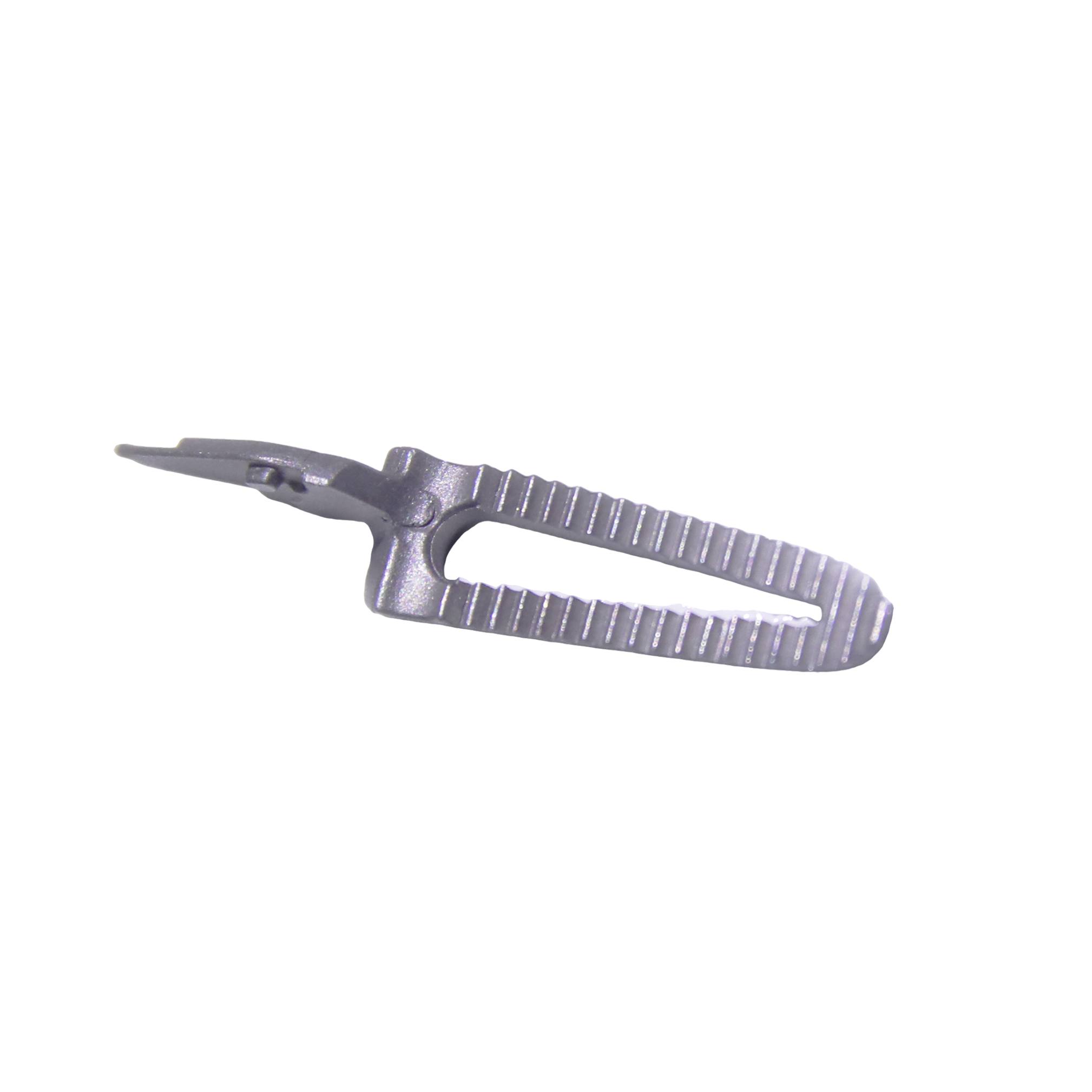

Laparoscopic Chuck Medical Metal Powder Metallurgy Parts

Metal Chuck for Laparoscopic Instruments

Our metal chuck is designed specifically for use in reusable laparoscopic instruments, offering high performance and reliability through advanced metal powder metallurgy.

Material: 316L, 17-4PH stainless steel

Length: 40mm - 60mm (customizable)

Maximum clamping force: 15N

Surface treatment: polishing (roughness Ra < 0.4µm)

Scope of application:

Designed for laparoscopic surgical instruments, such as grasping forceps, dissecting forceps and needle holders, suitable for routine and complex laparoscopic surgical scenarios.

Main Features:

Reliability:

- Excellent grip during tissue grasping and dissection, ensuring stable and precise handling.

- Minimizes risk of slipping with contoured jaw design, enhancing surgical control.

- High corrosion resistance and durability to withstand repeated sterilization cycles.

Versatility:

- Modular design allows for easy disassembly, reprocessing, and maintenance, making it ideal for reusable laparoscopic instrument systems.

Force Transmission:

- Effectively transmits mechanical force from the jaws to the instrument handle, enabling precise adjustment of gripping pressure, suited for delicate tissue handling.

This metal chuck provides dependable control, durability, and ease of use, supporting the needs of modern laparoscopic surgical procedures.

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays and weekends.

Customer Support

Your satisfaction is our priority.

We offer comprehensive Lifetime Technical Support and Warranty Services.

Contact Us

WhatsApp: +86 180 0255 3024

Email: market@mim-supplier.com

Shipping Information

We usually send samples to you via DHL FedEx or UPS.

Bulk goods will be shipped by sea to save shipping costs

FAQ’s

What materials do you provide?

We offer a wide range of materials for powder metallurgy.

MIM: 304 316 420 17-4 Stainless Steel, TC4 TA2 Titanium Alloys, AISI 310S Nickel-Chromium-Iron Alloys

CIM Process: Zirconia, Alumina, Silicon Nitride, Silicon Carbide, and Aluminum Nitride

Our R&D team can develop customized materials to meet your specific application requirements.