Порошковая металлургия — это метод обработки, при котором в качестве сырья используется металлический порошок, который прессуется и спекается для изготовления различных продуктов. Это не новый процесс или технология, и его можно проследить еще до Древнего Египта. Однако в сегодняшнем стремлении к устойчивому развитию и зеленому развитию он соответствует развитию времени и используется все больше и больше. Сегодня давайте рассмотрим этот метод производства, который может предоставить новый выбор для каждого способа изготовления деталей.

Процесс

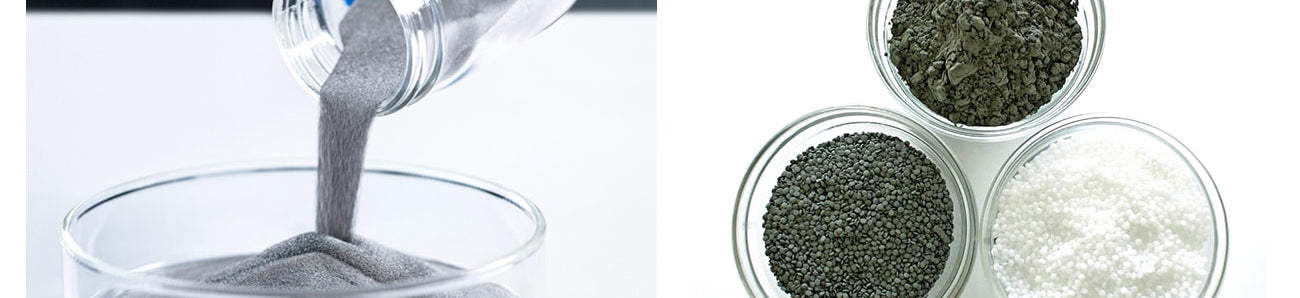

Порошковая металлургия похожа на ковку или литье, но разница в том, что ее сырьем является металлический порошок (обычно железо, сталь, медь и т. д.). Порошковое сырье прессуется при комнатной температуре (в особых случаях с подогревом) с использованием сложных пресс-форм. Размер прессованной заготовки близок к готовому изделию, но ее механические свойства еще нестабильны. Чтобы еще больше укрепить ее, ее затем спекают при температуре, близкой, но немного ниже температуры плавления используемого металла. При этом изменится микроструктура изделия, и будет получена деталь с точными размерами и высокой прочностью.

В общем, детали, полученные методом порошковой металлургии, можно использовать напрямую, но их также можно обрабатывать для вторичной обработки по мере необходимости, например, отделкой, термической обработкой, гальванопокрытием или покрытием, дробеструйной обработкой и т. д., чтобы улучшить или улучшить допуск, плотность, прочность, форму, коррозионную стойкость и другие свойства деталей. Преимущества порошковой металлургии По сравнению с другими технологиями производства и изготовления порошковая металлургия практически не производит отходов материала, коэффициент использования материала превышает 97%, и она может напрямую формировать сложные геометрические формы и поддерживать жесткий контроль допусков размеров в спеченных изделиях, что может сократить или даже полностью исключить операции обработки в традиционных производственных процессах. Вот почему мы называем это зеленой производственной технологией. В дополнение к экономии, которую приносят эти процессы, порошковая металлургия имеет свою собственную уникальность. Она использует преимущество своего сырья в виде порошков для достижения некоторых элементов управления, которые трудно или невозможно достичь при традиционной обработке, таких как контроль соотношения комбинаций химического состава, контроль микроструктуры и контроль пористости. Давайте рассмотрим несколько конкретных примеров продуктов, чтобы облегчить понимание.

1. Объединение несовместимых материалов

Порошковая металлургия позволяет комбинировать материалы, которые обычно считаются несовместимыми, и перерабатывать их в тесные гибридные формы.

Установленные примеры таких применений порошковой металлургии включают: Фрикционные материалы для тормозных накладок и поверхностей сцепления, где ряд неметаллических материалов (используемых для придания износостойкости или контроля уровней трения) внедрены в медную или железную матрицу. Твердые сплавы обычно используются для режущих инструментов, формовочных инструментов или абразивов. Они включают твердую фазу, связанную с металлом, микроструктуру, которая может быть получена только путем жидкофазного спекания при температурах выше точки плавления связующего вещества. Карбид вольфрама, связанный с кобальтом, является основным примером такого материала, но также доступны и другие твердые сплавы, включая ряд других карбидов, нитридов, карбонитридов или оксидов, а в качестве связующих веществ могут использоваться и другие металлы, помимо кобальта (Ni, Ni-Cr, никель-кобальт и т. д.).

Материалы для алмазного режущего инструмента, где мелкая алмазная крошка равномерно распределена в металлической матрице. Опять же, для обработки этих материалов применяется жидкофазное спекание. Электроконтактные материалы, такие как медь/вольфрам, серебро/оксид кадмия.

2. Обработка материалов с очень высокими температурами плавления

Технология порошковой металлургии позволяет обрабатывать материалы с очень высокими температурами плавления, включая тугоплавкие металлы, такие как вольфрам, молибден и тантал. Такие металлы трудно производить плавкой и литьем, и в литом состоянии они часто очень хрупкие. Производство вольфрамовых заготовок было одним из ранних применений порошковой металлургии, которая впоследствии использовалась для волочения проводов для ламп накаливания.

3. Изделия с контролируемой пористостью

Технология порошковой металлургии позволяет производить продукцию с контролируемой структурной пористостью. Спеченные фильтрующие элементы являются примером такого применения. Другим важным примером являются маслоудерживающие или самосмазывающиеся подшипники, одно из старейших применений порошковой металлургии, в котором взаимосвязанная пористость в спеченной структуре используется для удержания смазочного масла.

4. Продукция с превосходными свойствами

В некоторых конкретных приложениях процесс порошковой металлургии часто может производить превосходные свойства за счет превосходного контроля микроструктуры, в отличие от обычных процессов литья или ковки. Хорошими примерами таких приложений являются:

Магнитные материалы

Почти все твердые (постоянные) магниты и около 30% мягких магнитов обрабатываются из порошкового сырья. По сравнению с коваными изделиями, быстрорежущей сталью, обработанные порошковой металлургией материалы имеют более тонкую и контролируемую микроструктуру, более высокую прочность и производительность резки. Жаропрочные сплавы на основе никеля или кобальта Жаропрочные сплавы на основе никеля или кобальта используются в аэрокосмических двигателях, где процессы порошковой металлургии могут обеспечить диапазон состава и контроль микроструктуры, которые не могут быть достигнуты традиционным способом, тем самым улучшая рабочие температуры и производительность. Ограничения порошковой металлургии Хотя порошковая металлургия имеет различные преимущества, все еще существуют некоторые ограничения в ее применении. Основные моменты следующие:

(1) Размер и вес детали ограничены: порошковая металлургия требует процесса прессования в ходе процесса, который будет использовать пресс. Поэтому из-за текущих ограничений тоннажа пресса размер не может быть сделан очень большим, как правило, около 250 мм максимум. Кроме того, из-за ограниченной текучести металлических порошков все еще сложно производить детали весом более 20 кг с использованием процесса порошковой металлургии.

(2) Не подходит для ударных и динамических нагрузок Поскольку плотность деталей из порошковой металлургии обычно низкая, их прочность и ударная вязкость не так хороши, как у кованых или обработанных деталей. Поры, присутствующие после прессования и спекания порошка, также влияют на механические свойства материала. Это делает детали из порошковой металлургии менее подходящими для приложений с высоким напряжением и высокой деформацией, таких как ударные и высокие динамические нагрузки.

(3) Более высокие затраты на оборудование и пресс-формы

Процесс порошковой металлургии определяет необходимость использования специальных форм и оборудования, а стоимость относительно высока. Он неэкономичен при мелкосерийном производстве, поэтому порошковая металлургия обычно подходит для крупносерийного производства.

Share:

Состояние исследований в области технологии уплотнения порошковой металлургии

Что такое порошковая металлургия?