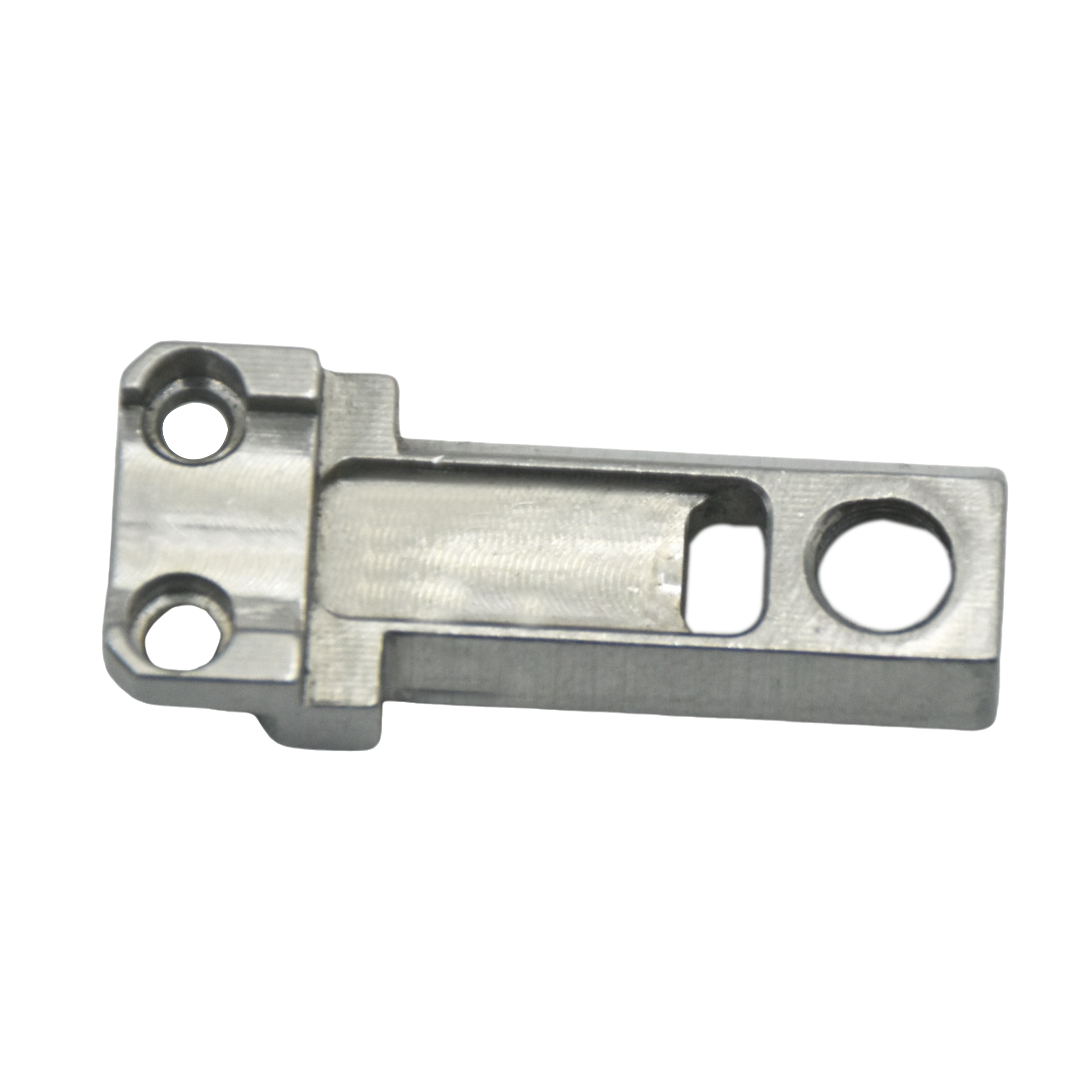

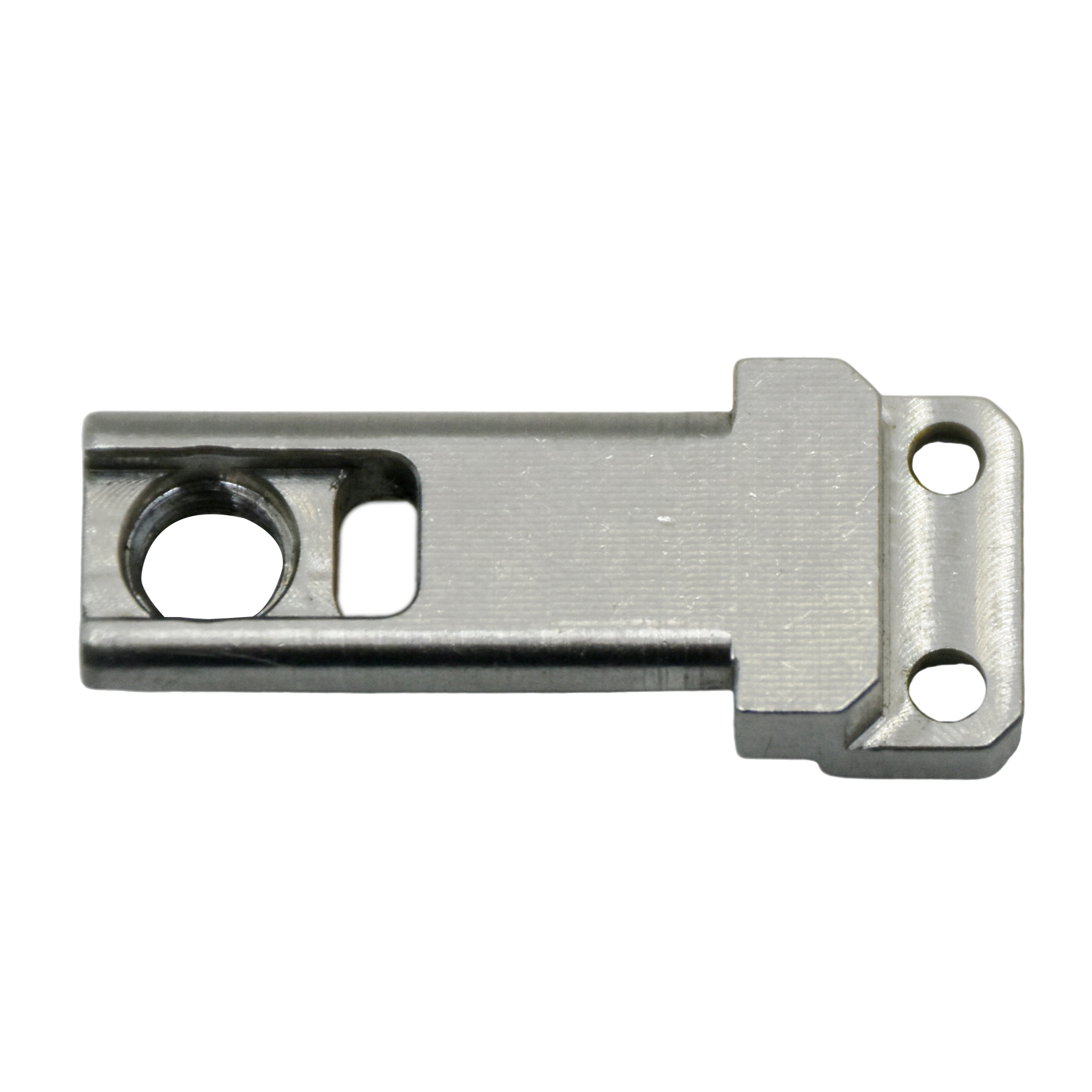

Marco de ajuste de lente óptico fabricado con MIM

Este marco de ajuste de lentes óptico, fabricado con tecnología de moldeo por inyección de metal (MIM), es un componente de vanguardia diseñado para sistemas ópticos de alta precisión. Su construcción robusta y diseño preciso lo hacen adecuado para aplicaciones en espejos láser, sistemas optomecánicos y plataformas electrosísmicas.

Características principales:

- Alta precisión dimensional: garantiza una alineación precisa de las lentes ópticas.

- Ligero y duradero: optimizado para el rendimiento sin peso adicional.

- Capacidades de geometría compleja: admite diseños complejos para configuraciones ópticas avanzadas.

- Resistente a la corrosión: Soporta entornos exigentes, lo que garantiza confiabilidad a largo plazo.

Parámetros técnicos:

| Parámetro | Valor | Observaciones |

|---|---|---|

| Material | Acero inoxidable MIM-316L | Alta resistencia a la corrosión |

| Tolerancia dimensional | ±0,02 mm | Adecuado para montaje de precisión. |

| Peso | 25 gramos | Ligero para facilitar la integración. |

| Rugosidad de la superficie | Ra 0,8 µm | Acabado suave para un rendimiento óptimo. |

| Temperatura de funcionamiento | -40°C a +150°C | Fiable en condiciones extremas |

| Capacidad de carga | 2,5 kilos | Admite configuraciones ópticas robustas |

| Solicitud | Espejos láser, plataformas electrosísmicas, sistemas ópticos |

Este marco de ajuste es la solución perfecta para profesionales que exigen precisión, durabilidad y rendimiento avanzado en aplicaciones ópticas. ¡Contáctenos para obtener más información o solicitar una muestra!

Si tiene alguna pregunta, siempre puede contactarnos. Le responderemos lo antes posible, dentro de las 24 horas, los días hábiles y los fines de semana.

Atención al cliente

Su satisfacción es nuestra prioridad.

Ofrecemos soporte técnico integral de por vida y servicios de garantía .

Contáctenos

WhatsApp: +86 180 0255 3024

Correo electrónico: market@mim-supplier.com

Información de envío

Generalmente le enviamos muestras a través de DHL FedEx o UPS.

Las mercancías a granel se enviarán por mar para ahorrar costes de envío.

Preguntas frecuentes

¿Qué materiales proporcionas?

Ofrecemos una amplia gama de materiales para pulvimetalurgia.

MIM: acero inoxidable 304 316 420 17-4, aleaciones de titanio TC4 TA2, aleaciones de níquel-cromo-hierro AISI 310S

Proceso CIM: Zirconia, Alúmina, Nitruro de Silicio, Carburo de Silicio y Nitruro de Aluminio

Nuestro equipo de I+D puede desarrollar materiales personalizados para satisfacer los requisitos de su aplicación específica.