Tungsten MIM (Tungsten Metal Injection Molding) is a complex process for custom tungsten manufacturing. This technology combines the advantages of powder metal technology with the flexibility of metal injection molding technology to produce complex and high-density tungsten parts.

Tungsten MIM (Tungsten Metal Injection Molding) Tungsten alloy produced by tungsten metal injection molding has the characteristics of high melting point, high density, high thermal conductivity, low thermal expansion coefficient (CTE), etc. Common tungsten materials include W, ODS-W (oxide dispersion strengthened tungsten), W-Re (tungsten rhenium), W-Cu (tungsten copper), WHA (tungsten high specific gravity alloy). Therefore, it has been widely used in many high-tech fields.

Applications of Tungsten Metal Injection Molding

Tungsten metal injection molding plays an important role in many industries. Here are some of the main application areas:

Aerospace:

Tungsten metal injection molding is often used for key components of aerospace equipment. Tungsten is an ideal material in the aerospace field due to its high melting point and strength. Such as nozzles, engine components and high-temperature detectors, it can effectively improve the durability and performance of components, thus making a great contribution to the aviation industry.

Medical devices:

Tungsten's biocompatibility and antibacterial properties make it suitable for medical devices, which can effectively reduce the body's rejection and reduce the risk of infection. Such as surgical tools and implants, which can withstand high-temperature sterilization and harsh use environments.

Electronic products:

Tungsten's electrical conductivity and high-temperature resistance are very suitable for the miniaturization and high-precision requirements of modern electronic products. Tungsten's electrical conductivity makes electronic connectors, electric contacts and poles to ensure the electrical performance of the equipment. Tungsten's high thermal conductivity can effectively manage heat, prevent equipment from overheating, and ensure the normal operation of the equipment.

Energy industry:

In the nuclear energy and oil and gas industries, tungsten mim is used as a component and protective material for high-temperature furnaces. It can withstand the working environment of extreme environments and is often used in high-temperature furnaces, reactor components and other key components. Secondly, tungsten's high corrosion resistance enables it to perform well in harsh chemical environments, extending the service life of equipment and reducing maintenance costs.

As an advanced manufacturing technology, tungsten metal injection molding has become an indispensable part of many high-tech industries with its unique advantages and wide application potential. With the continuous development of materials science and processing technology, the application prospects of tungsten will be broader and will surely promote more innovations and breakthroughs.

Share:

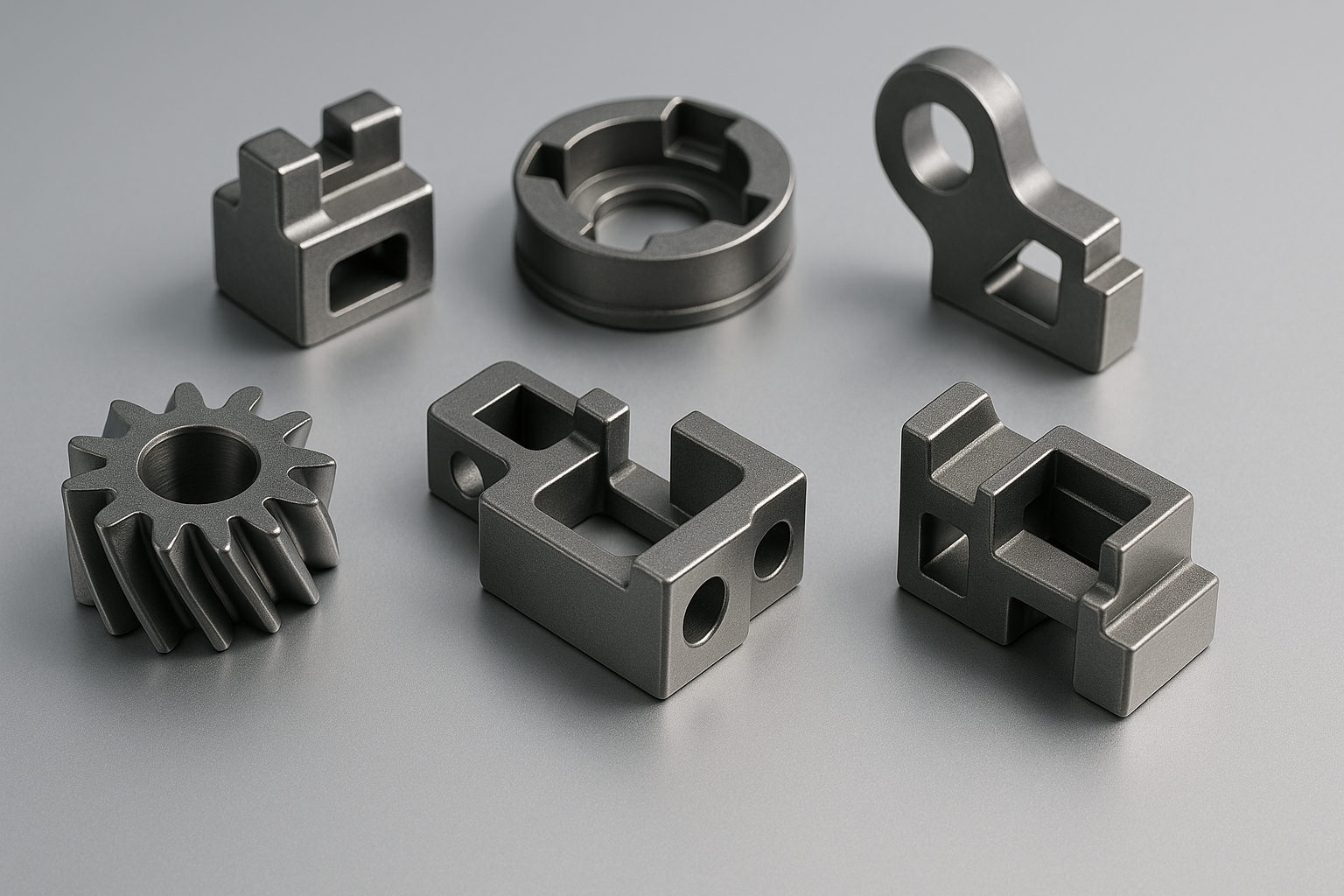

Advantages of Micro Metal Injection Molding

Customized High Precision Powder Metal Gears