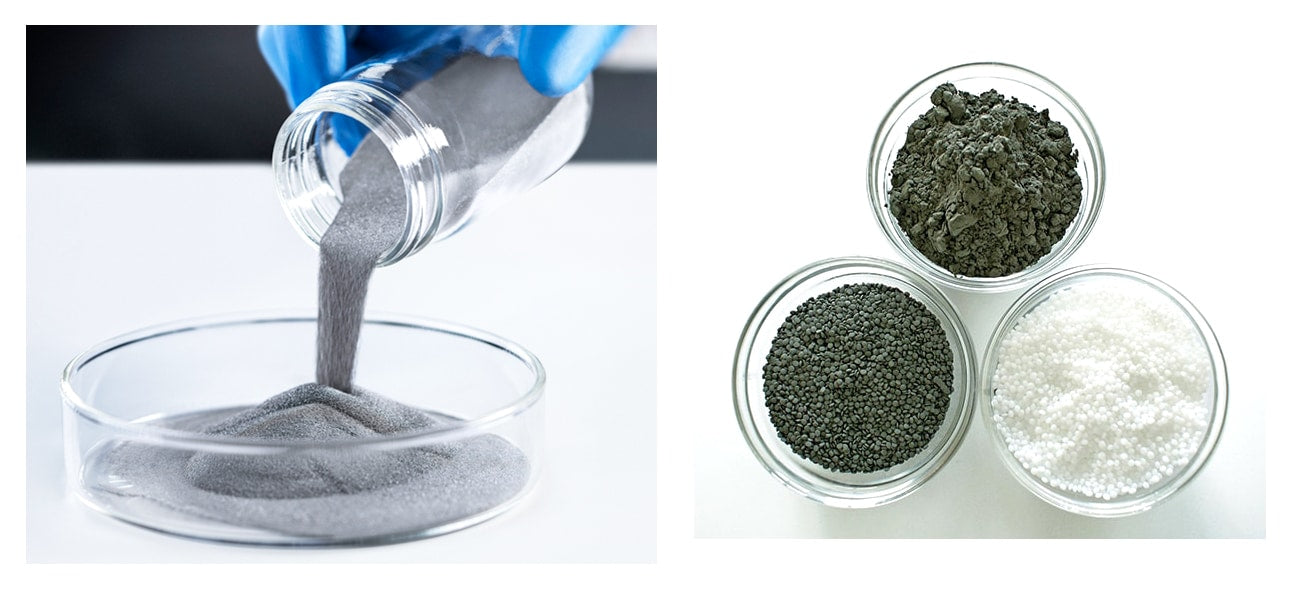

MIM is a technology that mixes metal powder with various resins called binders, uses an injection molding machine to mold the raw materials processed into a fluid, and then sintering to achieve near-net-shape production of three-dimensional complex-shaped metal parts. It is used in a variety of applications from hobbies to automobiles and medical fields.

Features

● Three-dimensional complex shapes

Molding is performed through injection molding, so it can achieve dead angles and threaded shapes like resin molding.

It can achieve the integration of parts used for assembly and shapes that are difficult to mass produce with other processes.

● Material freedom

Applicable to a wide range of materials such as iron-based low alloys, stainless steel, magnetic materials, high-hardness wear-resistant parts, etc.

● High density

The raw metal powder uses micropowders below 10μm, so it is easy to achieve high density,

and the density can reach more than 97% of the true density. The pores are also independent micro-levels of several μm,

so various characteristics are comparable to those of smelted materials.

● Small Applicable to small parts

It can achieve mass production of small parts that are difficult to achieve with other processes.

Our advantages:

Personalization

Lifetime warranty

Free samples

Free technical support

Share:

How μ-Mim Technology Helps Medical Device Development

Is Powder Metallurgy Expensive?