Medical device manufacturing is a very important industry whose task is to produce high quality, high performance and reliable devices for patients. These devices include surgical instruments, pacemakers, magnetic resonance imaging machines and much more, and are essential for modern medical treatment.

Our company is specialised in medical device related projects. If you are interested in defibrillators, pacemakers, cochlear implants, dental medical devices and other related products, you can contact our engineers at edith@xy-global.com for a one-to-one communication about your project and an efficient solution to the problems you bring. We can quickly analyse the feasibility and DFM of your project and create a good communication environment for you.

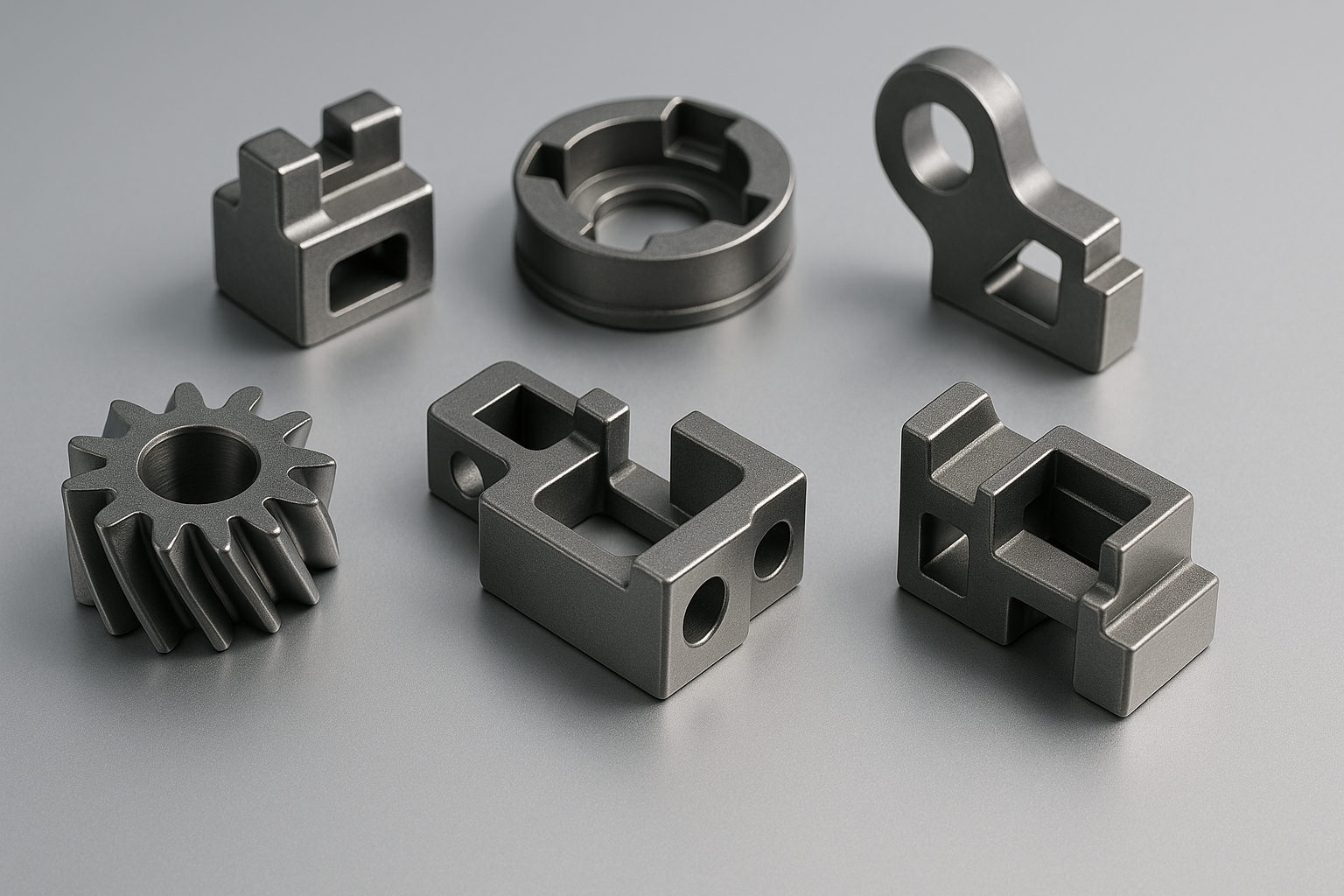

The manufacturing process of medical devices must comply with strict regulations and standards to ensure their safety and reliability. Every step of the manufacturing process must be controlled and monitored, including raw material procurement, processing and assembly.

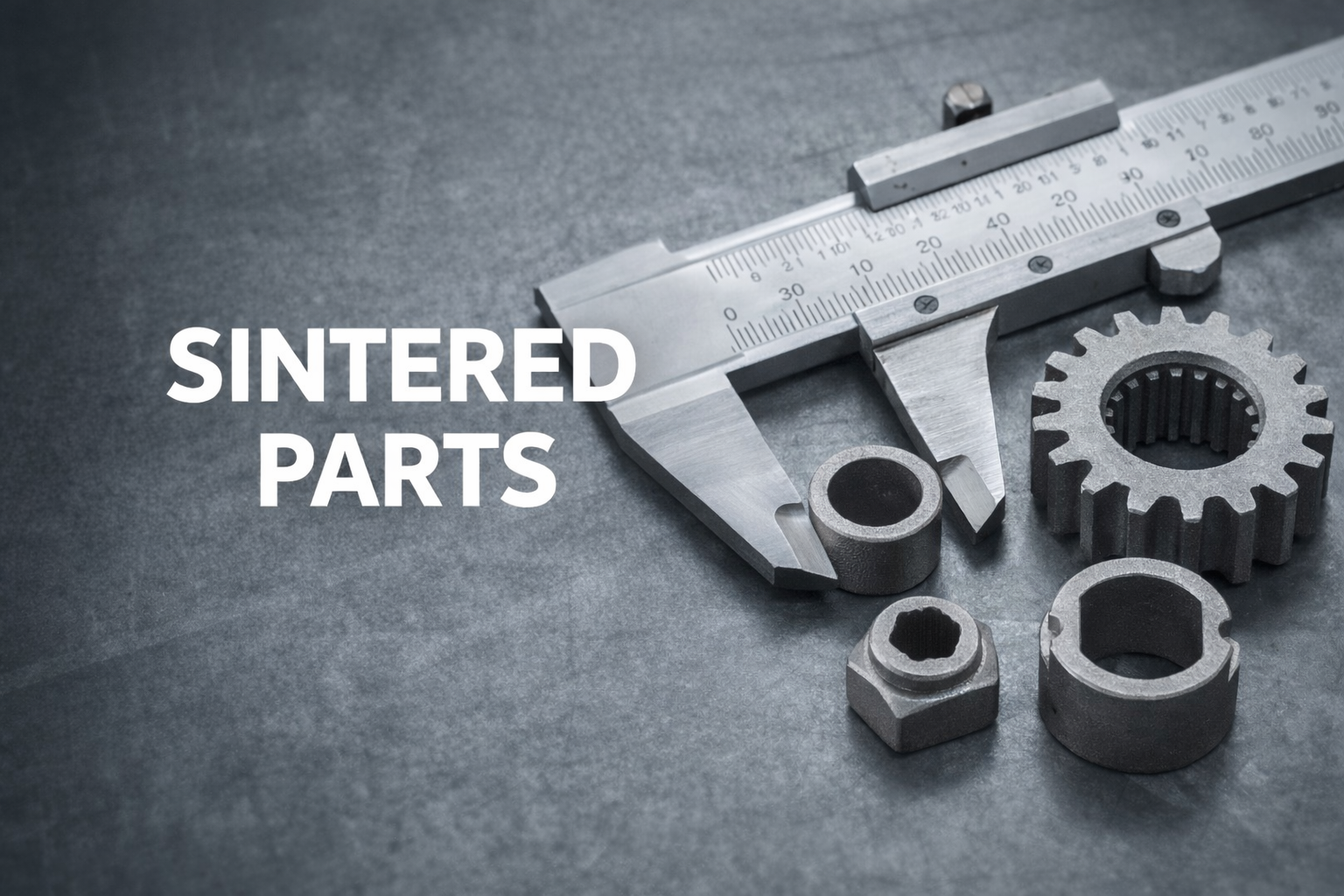

The manufacture of medical devices requires a variety of different technologies, including injection moulding, CNC machining, laser cutting and many more. These technologies must be selected and applied according to the specific device and requirements.

The manufacture of high quality medical devices requires highly specialised personnel and a strict quality management system. Manufacturers must have the relevant qualifications and certifications to ensure that their products comply with the relevant standards and regulations.

In conclusion, the manufacture of medical devices is an extremely important industry that is directly related to the health and lives of patients. Only through strict quality control and professional application of technology can high quality products be produced that meet the standards and requirements.

Share:

What Are Blind Holes in Engineering and Machining?

Associated Effects of Bone Screws