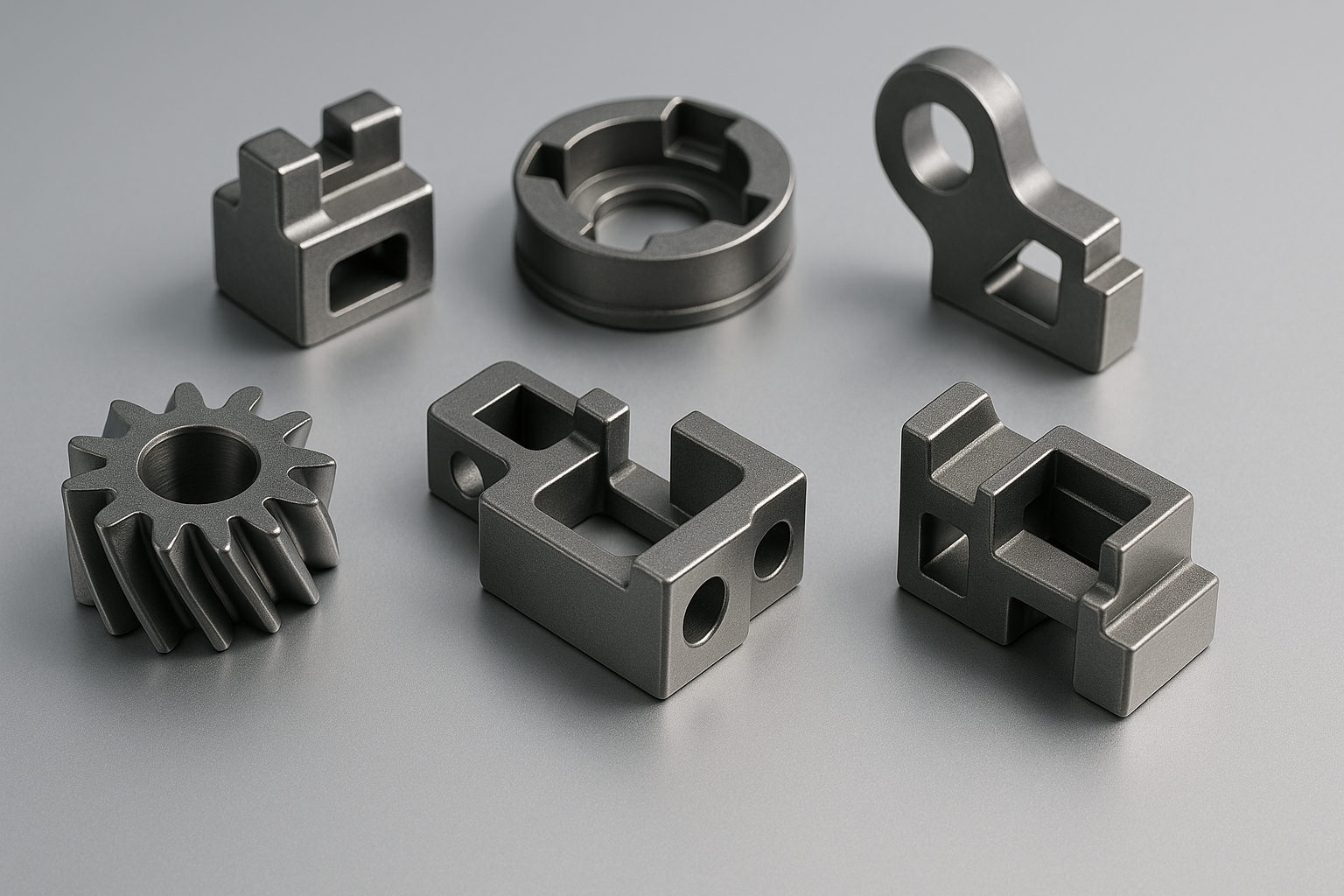

Micro Metal Injection Molding (Micro MIM) is an advanced technology that integrates metal injection molding with micromachining services, enabling the high-volume production of complex, miniature metal parts. This article explores the micro MIM process, its technical foundations, application areas—especially in the medical industry—and key design and production considerations for achieving high-precision results.

Micro Metal Injection Molded Gears for the Medical Industry

1. What is Micro Metal Injection Molding?

Micro MIM is a specialized form of traditional metal injection molding, enhanced to produce parts with micro-scale features. It combines:

-

Powder metallurgy

-

Injection molding techniques

-

Micromachining services

This hybrid approach allows for the production of dense, intricate metal parts with superior mechanical performance.

2. The Micro MIM Process Explained

Step-by-Step Overview:

-

Feedstock Preparation

Metal powder is mixed with a polymer binder to form a flowable material. -

Micro Injection Molding

The mixture is injected into precision micro molds at high pressure. -

Debinding

Binders are removed, leaving only the metal particles in the desired shape. -

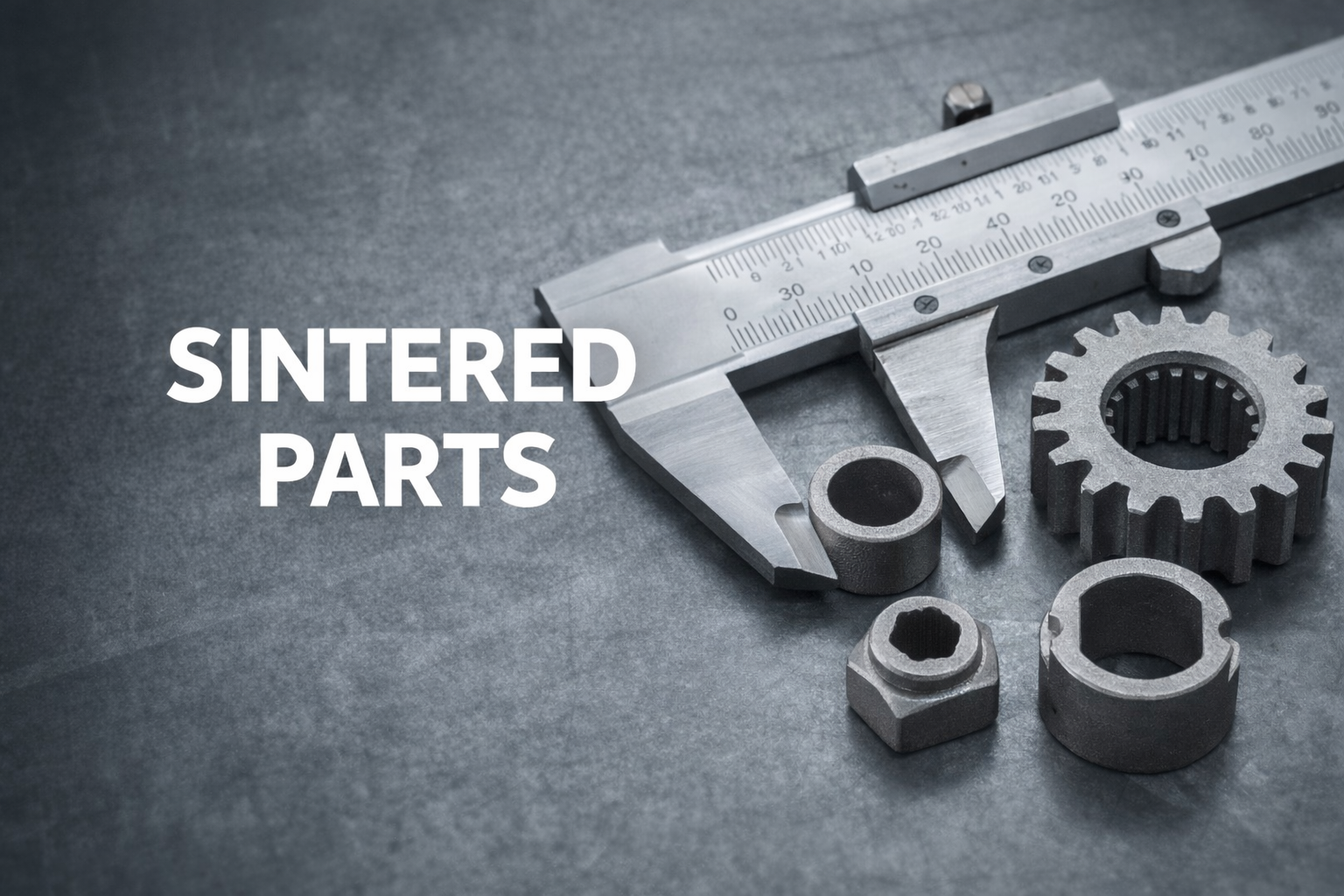

Sintering

Parts are heated to just below their melting point, causing the particles to fuse into dense components. -

Post-Processing

Optional processes like grinding or polishing refine surface finish and dimensional accuracy.

This tightly controlled micro MIM process is essential for producing miniature components with tight tolerances and excellent repeatability.

3. Applications: Micro Molding for Medical Devices

One of the most significant application areas is micro molding medical devices. Micro MIM is ideal for:

-

Micro gear systems in surgical instruments

-

Miniature orthopedic implants

-

Precision dental device components

These medical-grade parts benefit from the strength, precision, and biocompatibility that micro metal injection molding offers.

4. Key Design & Manufacturing Considerations

Material Selection

Use high-quality, fine metal powders with excellent sinterability and the right mechanical/corrosion properties. Binder compatibility is also crucial.

Molding Parameters

Optimize injection speed, pressure, and temperature for complete mold filling and dimensional control.

Sintering Conditions

Carefully control sintering temperature and atmosphere to ensure density and strength.

Mold Design

Precise micro mold design improves material flow, reduces shrinkage, and ensures smooth demolding.

Post-Processing

Machining, polishing, and other micromachining services may be applied to meet high surface quality standards.

5. Why Choose XY GLOBAL for Micro MIM?

At XY GLOBAL, we deliver precision through a rigorous micro MIM process backed by an expert engineering team. Our advantages:

-

Online quoting and DFM analysis within minutes

-

Rapid prototyping

-

Custom solutions for micro MIM and micro molding medical devices

-

On-demand production of complex miniature components

Ready to bring your micro components to life?

Partner with XY GLOBAL to access cutting-edge micro metal injection molding capabilities and expert guidance from design to delivery.

Share:

China Sintered Parts Manufacturer | Sintered Bronze Bushings & Custom Alloys

Micro Metal Injection Molding Precision Solutions for Small Parts