Knowledge

What Alloy Materials Are Needed for Aerospace Engines?

Difference Between Tungsten Carbide Spraying and Welding

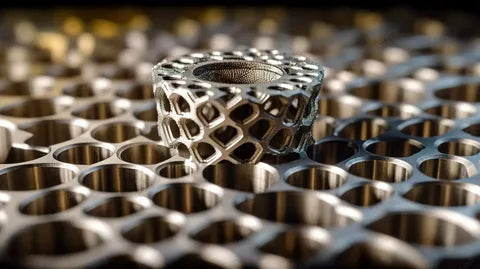

Iron-Based Alloys of Metal Powder Injection Molding Materials

Limitations and Development Trends of Metal Powder Injection Molding

International Cooperation in Powder Injection Molding

Application of Metal Injection Molding (MIM) in the Medical Field

Introduction to the Basic Principle of Sintering

Preparation of Powder Metallurgy 316L Stainless Steel

Dip Filling and Electroplating of Castings and Powder Metallurgy Parts