Knowledge

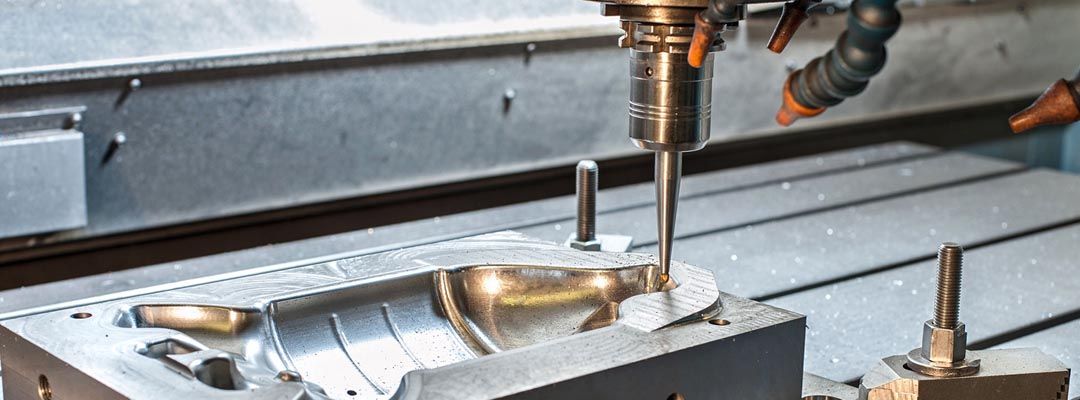

CNC EDM Machine: A Tool for Precision Manufacturing

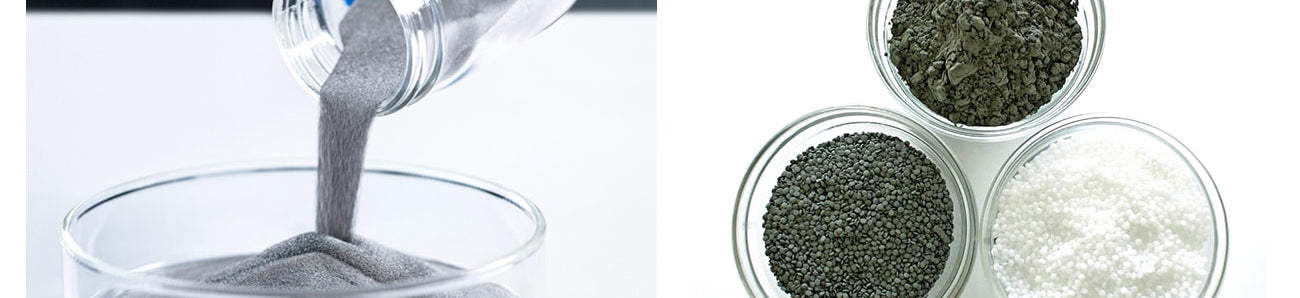

Advanced Ceramic Injection Molding - A Great Process

Green Manufacturing Technology - Powder Metallurgy

Research Status of Powder Metallurgy Densification Technology

Top 100 National Injection Molding Companies

Introduction to Sizing Process in Powder Metallurgy

Low-Cost Powder Metallurgy Titanium Alloy Shape Control Integration

Composition and Properties of Cemented Carbide