Knowledge

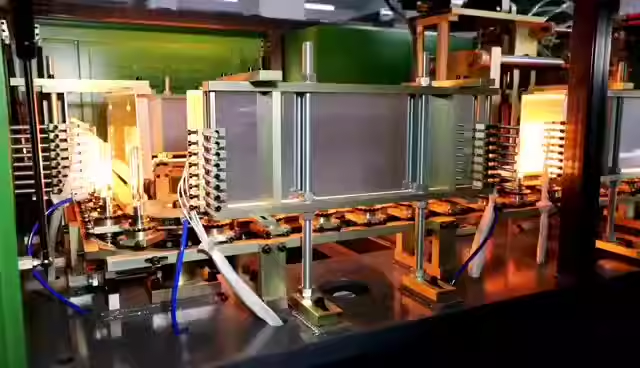

Considerations in Metal Injection Molding Manufacturing

Metal Injection Molding, Steering the Automotive Industry

What Are MIM’s Advantages over Other Processes

How a Medical Device Supply Chain Works

Revolutionizing MIM Processes for Motor Fan Blades

Precision Parts Processing Needs to Follow 4 Principles

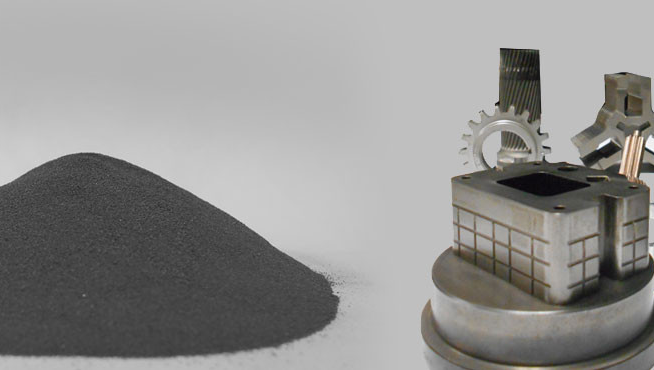

Material Selection and Application in Metal Powder Metallurgy

Four Processes for Making Metal Powder