Sprue, Runner, and Gate

The flow path into the mold cavity consists of a sprue, runner, and gate. The molding machine nozzle seats itself into the sprue bushing of the mold to deliver molten feedstock into the cavity. In mold designs MIM molders try to produce as little waste as possible. This means sprue diameters and runners should be kept as small and short as possible, but need to be large enough to fully pack the cavity. In many MIM operations sprues are tapered with a typical diameter near 6 mm and a 5 degree taper. When the mold opens for ejection, the sprue is ejected and recycled. For faster production and the reduction of regrind, the sprue and/or runner can be kept hot to avoid reheating and recycling this portion of the feedstock. This option is called a hot runner system or hot sprue.

From the molding nozzle the sprue leads into the runner, which then directs the melt into the mold cavity through the gate. Small runners allow for slow filling, so a large runner is desirable, with a typical diameter from 3 to 6 mm. Of course a large runner means relatively less of the shot goes into the part cavity. A circular runner design is desirable since this reduces friction and heat loss during filling, but other designs are less expensive to construct. Multiple cavity molds require balanced designs so the feedstock flow length is the same for each cavity.

MIM sprues and runners can be ground and re-molded. The metal powder is virtually unaffected by the molding cycle and the plastic will eventually be removed/destroyed anyway.

At the end of the runner is the gate leading into the mold cavity. The gate leaves a surface blemish on the part. It is small and designed to freeze before the part, runner, or sprue freeze. This keeps the cavity packed to avoid sink marks (recessed surfaces) during cooling. Excessive pressure on gate freezing causes sticking in the mold. It is desirable to have the gate located on the thick portion of the component. This reduces heat loss and premature freezing and lowers the pressure required for mold filling.

Gate size is determined by filling speed and component thickness and is an area of expertise for MIM tool designers. Usually the gate is smaller than the component wall thickness. But too small a gate can introduce defects, tool wear, and incomplete filling. Small gates also contribute to powder-binder separation, which is a cosmetic defect.

Gate placement considers how to minimize weld lines. Weld lines form when the feedstock splits and then rejoins after flow around posts or other features. If the molding conditions are such that the feedstock is warm, then the weld line heals. Alternatively, if the feedstock cools, then a weld line defect forms. Computer simulations (mold flow analysis) help avoid these difficulties by suggesting either different molding parameters or different gate locations.

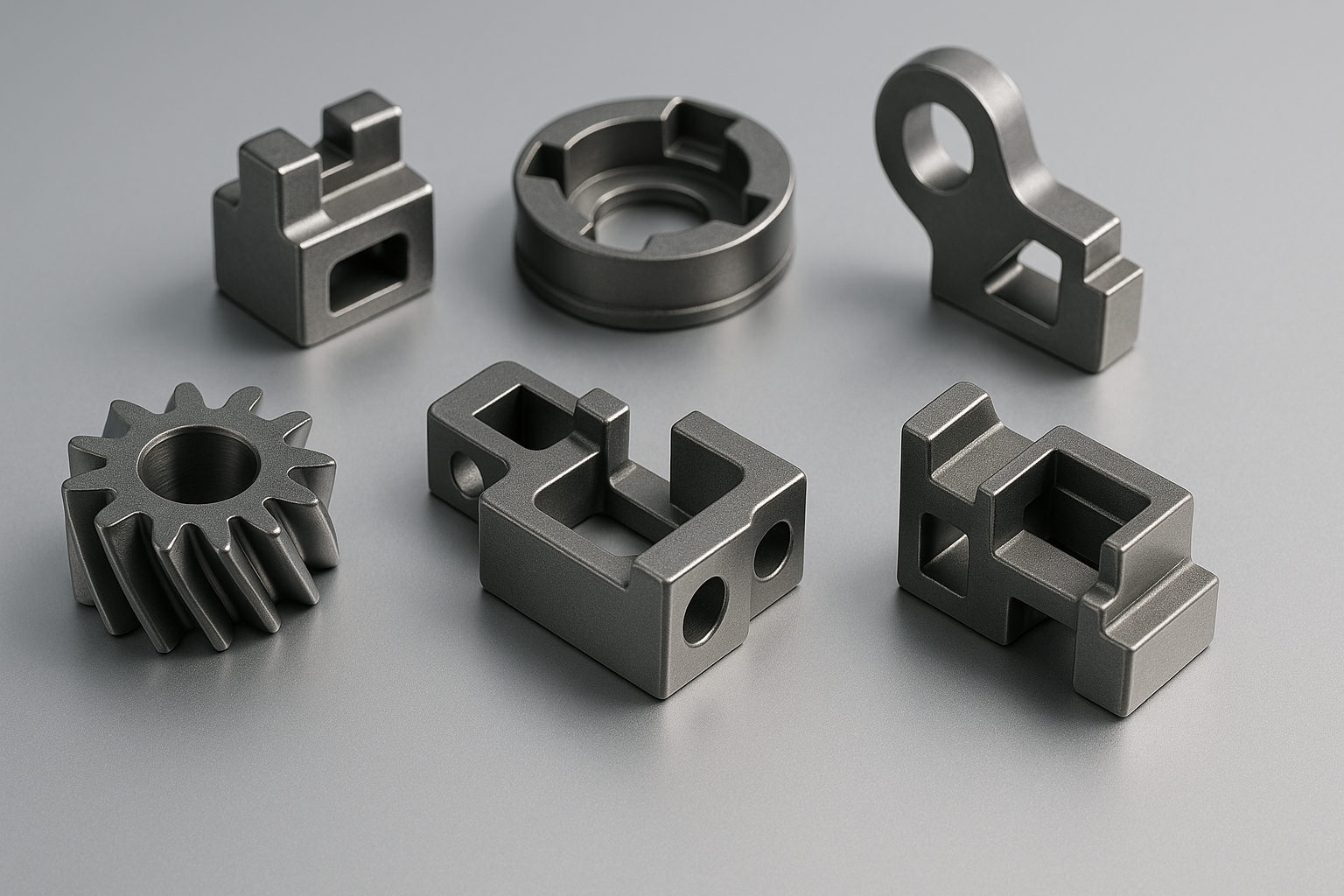

If you have metal powder metallurgy parts for semiconductor, medical and optical applications, please send us a drawing enquiry for further evaluation.

Share:

Metal Injection Molding, Steering the Automotive Industry

Vacuum Sintering of Electronic Devices