Working Principle

The working principle of CNC EDM Machine is based on the phenomenon of electric spark discharge. In the machine tool, high-frequency and high-voltage discharge is generated between the tool electrode and the workpiece, generating high temperature, which causes the metal to melt and gasify rapidly, thereby achieving material removal. Main Components CNC System: Controls the precise movement of each axis of the machine tool to achieve the processing of complex shapes. Servo System: Accurately drives the movement of the machine tool axis according to the instructions of the CNC system. Spindle: Fixed tool electrode, can move up and down and rotate.

Workbench: Carries the workpiece and can move in multiple directions.

Pulse Power Supply: Provides high-voltage and high-frequency pulses to generate electric sparks. Cooling System: Cools the tool electrode and workpiece to prevent overheating.

Application fields Complex shape processing: suitable for processing parts with complex shapes and high precision requirements. Hard material processing: can process materials with high hardness and difficult to cut.

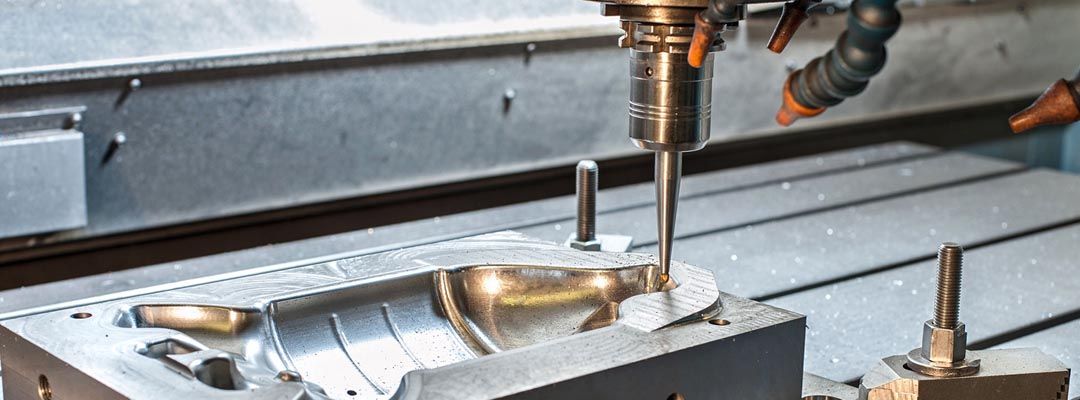

Mold manufacturing: used to manufacture precision plastic molds and die-casting molds.

Micromachining: suitable for micromachining with micron or even nanometer precision. Processing process programming: use CAD/CAM software to design workpiece models and processing paths.

Clamping: fix the workpiece on the workbench.

Setting parameters: set pulse power supply parameters according to material and processing requirements. Processing: start the CNC system for automatic processing.

Inspection: after processing, check the size and surface quality of the workpiece.

Technical advantages High precision: can achieve a processing accuracy of ±0.005mm.

High surface quality: the processing surface has good finish and no cutting marks.

High efficiency: compared with traditional cutting, EDM is faster.

Non-contact processing: the tool electrode does not directly contact the workpiece, reducing wear.

Development trend Intelligence: integrate intelligent algorithms to improve processing efficiency and automation level.

Green manufacturing: reduce energy consumption and material waste during processing.

Multi-axis machining: develop multi-axis linkage technology to achieve complex spatial surface machining.

Micro-nano machining: expand into the field of micron and nano precision machining.

As a high-precision and high-efficiency advanced manufacturing equipment, CNC EDM machine tools have an irreplaceable position in modern industrial production. With the continuous advancement of technology, CNC EDM machine tools will become more intelligent and precise, meeting the demand of the manufacturing industry for high-quality products.

Share:

Advanced Ceramic Injection Molding - A Great Process

Dip Filling and Electroplating of Castings and Powder Metallurgy Parts