High nitrogen steels are steels with a high nitrogen content which have a wide range of applications in micro metal injection moulding (MIM). The following are some important points regarding the use of high nitrogen steels in MIM:

1. Strength and hardness: High-nitrogen steels have excellent strength and hardness properties due to their high nitrogen content. This makes high nitrogen steels very useful in the manufacture of micro parts that require high strength and hardness, such as precision tools, components and cutters.

2. Corrosion resistance: High nitrogen steels have good corrosion resistance due to their high nitrogen content. This makes high nitrogen steels useful in the manufacture of micro components that need to resist corrosive environments, such as medical devices, electronic equipment and chemical processing equipment.

3. Machinability: High Nitrogen steels have good machinability in the MIM process. Due to its suitable flowability and compressibility, high nitrogen steel powders can be mixed with the appropriate binder and processed by the injection moulding process. This facilitates the mass production of high-nitrogen steel micro parts.

4. Cost-effectiveness: lower costs can be achieved by using MIM for the manufacture of high-nitrogen steel miniature parts compared to traditional machining methods such as milling, turning and grinding, etc. MIM technology has a highly automated production process that enables the mass production of complex-shaped parts, thereby reducing production costs and labour hours.

5. Manufacture of complex shaped parts: MIM technology for high nitrogen steels makes it possible to manufacture complex shaped miniature parts. the MIM process enables the cavities to be fully filled, allowing the high nitrogen steel powder to precisely replicate the shape of the mould, resulting in complex, geometrically diverse miniature parts.

In summary, high nitrogen steels have a wide range of promising applications in micro metal injection moulding. Its excellent strength, hardness and corrosion resistance, combined with cost effectiveness and the ability to manufacture complex shaped parts, make high nitrogen steels an ideal material choice for the manufacture of micro parts where high performance and precision are required.

The process aspects of high nitrogen steels in micro metal injection moulding (MIM) require the following key points to be considered:

1. Material preparation: The selection of a suitable high nitrogen steel powder is a key step. The high nitrogen steel powder should have the flowability and sinterability to ensure that the mould cavity is adequately filled and the desired part shape is formed during the injection moulding process.

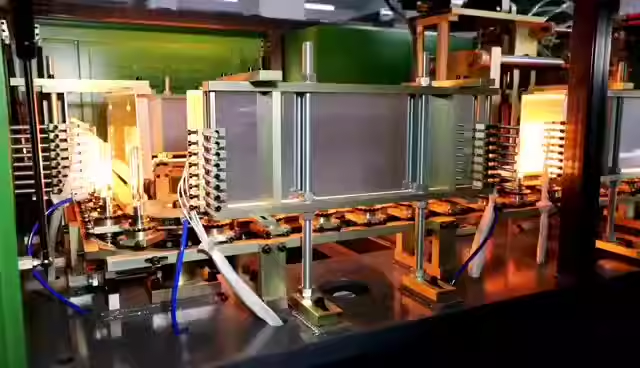

2. Mixing and injection moulding: The high nitrogen steel powder is usually mixed with a polymer binder to form an injection material with a certain degree of fluidity. The mixing process involves controlling the ratio of powder to binder and the mixing time to ensure uniform dispersion. The injection material is then injected into a miniature mould by an injection moulding machine. The injection moulding parameters such as injection pressure, injection speed and injection temperature need to be optimised.

3. Sintering and binder removal: After injection moulding the parts are subjected to a sintering process. The control of sintering temperature and time is important to ensure that the binder is completely removed during the sintering process and that the high nitrogen steel particles are bonded to each other to form a dense structure. The choice of atmosphere during the sintering process also plays an important role in the quality of the final product.

4. Post-treatment processes: After sintering, a number of post-treatment steps may be required to obtain the desired surface quality and precision. This may include steps such as machining, grinding, polishing, etc. to meet the requirements of the final product.

It is important to note that due to the high hardness and strength of high nitrogen steels, the effect of wear and thermal stress on the mould needs to be taken into account in the design and manufacture of the mould. Mould materials should be selected to have good wear resistance and thermal stability, while appropriate cooling measures need to be taken to control the temperature.

In addition, due to the high nitrogen content of high nitrogen steels, higher requirements may be placed on the design of gas removal and venting systems during the forming process to avoid the formation of air bubbles or porosity. In addition to the process considerations mentioned earlier, there are a number of other points of attention and optimisation to improve the performance and quality of high nitrogen steels in micro metal injection moulding (MIM), as follows:

1. Powder characteristics: The particle size and shape of the high nitrogen steel powder has an important influence on the quality of the moulding. Too large or too small a particle size can lead to uneven filling or high injection pressure. Therefore, the particle size distribution and shape of the powder should be in accordance with the required process parameters, and the necessary screening and treatment should be carried out.

2. Vacuum treatment: The use of vacuum treatment during injection moulding can effectively reduce or eliminate the presence of gas and reduce the formation of pores and defects. Proper vacuum treatment can improve the compactness and mechanical properties of the part.

3. Temperature control: Strict temperature control is essential during the injection moulding and sintering process. Too high or too low temperatures can lead to part deformation, uneven shrinkage or structural non-density. Therefore, temperature control by optimising heating, cooling and sintering parameters is required to achieve optimum part quality.

4. Ambient atmosphere: The choice of atmosphere during sintering has an important influence on the sintering results and properties of high nitrogen steels. The right atmosphere can avoid oxidation and pollution and ensure the quality and performance of high nitrogen steel parts.

5. Enhancement processes: For some special applications, enhancement processes can be considered to improve the performance of high N steel miniature parts. For example, processes such as heat treatment, heat deformation and surface treatment can further improve the hardness, strength and corrosion resistance of the material.

6. Quality control: Quality control is essential throughout the production process. Starting with the selection and inspection of raw materials, through to the control of process parameters and the inspection of parts, strict quality control is required to ensure that the quality and performance of the final product meets the requirements.

By considering all these aspects of attention and optimisation, the performance and quality of high nitrogen steels in MIM can be maximised to meet the requirements of specific applications.

XY-GLOBAL has a rigorous process for every step of the way from production to mass production. If you have a high nitrogen steel related part to make. contact xy-global and have your problem solved by a dedicated engineering team and get high quality on-demand parts with expert prototyping and production capabilities. quotations and DFM analysis can be completed online in minutes and quality parts can be delivered within days.

Share:

Micro Metal Injection Molding, The Future of Precision Manufacturing

Precision Parts Processing Needs to Follow 4 Principles