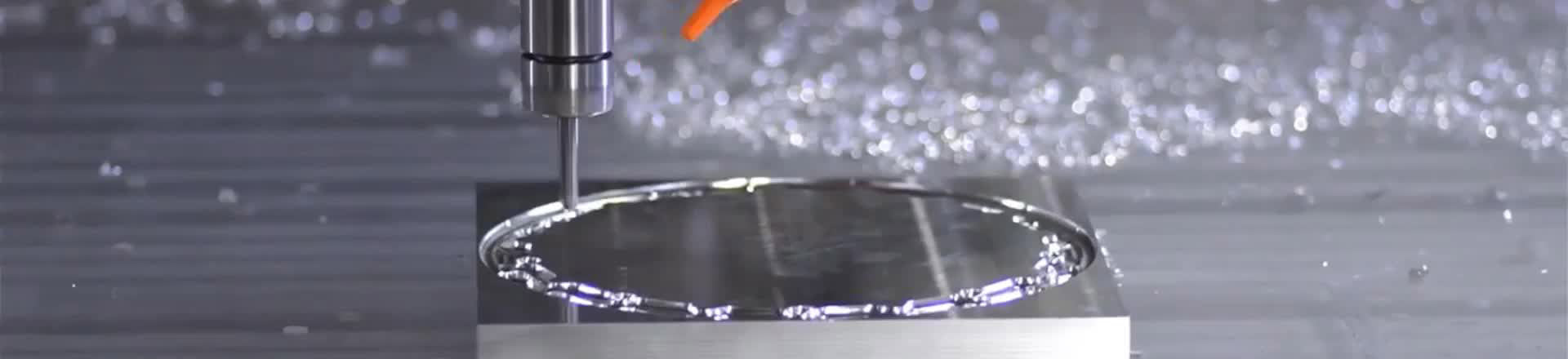

In today's highly developed medical field, precision CNC machining is playing a vital role. It not only provides high-precision and high-quality solutions for the manufacture of medical devices, but also promotes the continuous advancement of medical technology and brings more hope to the health of patients.

1. The importance of precision CNC machining in the medical industry

The medical industry has extremely high requirements for the accuracy and quality of equipment, because even a small error may have a significant impact on the treatment effect and life safety of patients. And precision CNC machining technology has become an ideal choice to meet this strict requirement with its excellent precision control and stability. For example, in the manufacture of implantable medical devices such as pacemakers and artificial joints, CNC machining can ensure that the size and shape of parts are accurate, thereby improving the compatibility and reliability of the equipment with human tissues. For another example, in the production of minimally invasive surgical instruments, precision CNC machining can produce extremely small and complex parts, making surgery more precise and safe.

2. Application fields of precision CNC machining in the medical industry

(I) Orthopedic medical devices The manufacture of orthopedic devices such as artificial joints and spinal fixation devices is inseparable from precision CNC machining. By precisely cutting and forming metal materials such as titanium alloys and stainless steel, parts that conform to the human anatomical structure are produced to help patients restore normal motor function.

(II) Cardiovascular medical devices Cardiovascular devices such as heart stents and heart valves need to have a high degree of consistency and reliability. CNC machining can produce devices with complex internal structures and precise dimensions to ensure their normal operation in the blood circulation system.

(III) Dental medical devices The manufacture of dental devices such as dental implants and dentures requires extremely high precision. CNC machining can customize perfectly matched devices based on the patient's oral data to improve treatment effects and comfort.

(IV) Medical diagnostic equipment Key components in high-end medical diagnostic equipment such as CT machines and MRI equipment also need to be processed by precision CNC to ensure their performance and accuracy.

3. Technical advantages of precision CNC machining

(i) High precision can achieve micron or even nanometer level precision, ensuring that key components of medical devices meet strict design requirements.

(ii) High repeatability maintains a high degree of consistency in large-scale production, ensuring the stable and reliable quality of each product.

(iii) Complex shape processing capabilities can produce parts with complex geometries and internal structures to meet the increasingly complex design needs of medical devices.

(iv) Material diversity is suitable for various medical-grade metal and non-metal materials, such as titanium alloy, cobalt-chromium-molybdenum alloy, polyetheretherketone (PEEK), etc.

4. Challenges and solutions Although precision CNC machining has many advantages in the medical industry, it also faces some challenges.

The first is the cost issue. Due to the extremely high requirements for precision and quality in the medical industry, CNC machining equipment and processes are often expensive, which increases the manufacturing cost of medical devices.

To meet this challenge, companies can reduce costs by optimizing production processes, improving equipment utilization and adopting advanced tool technology. The second is strict supervision and quality control. The medical industry is subject to strict regulations and standards, and the CNC machining process needs to meet a series of quality certification and testing requirements. Enterprises should establish a sound quality management system, strengthen the inspection and monitoring of raw materials, processing and finished products, and ensure that products comply with regulations and standards. Furthermore, the pressure of technological innovation is also increasing.

With the rapid development of medical technology, higher requirements are placed on the performance and functions of medical devices, and CNC processing technology also needs to be continuously innovated and upgraded. Enterprises should increase R&D investment, cooperate with scientific research institutions and universities, and jointly explore new processing techniques and technologies.

V. Future Development Trends Looking to the Future

The development prospects of precision CNC processing in the medical industry are very broad. With the continuous maturity of 3D printing technology, the combination with CNC processing will bring more innovative solutions to the medical industry. For example, complex prototypes can be manufactured through 3D printing, and then CNC processing can be used for fine processing and surface treatment, which can improve production efficiency and product quality.

At the same time, the application of intelligent and automated technologies will further improve the production efficiency and precision control level of CNC processing. By introducing robots, sensors and intelligent control systems, real-time monitoring and adaptive adjustment of the processing process can be achieved, human errors can be reduced, and production quality and stability can be improved.

In addition, as people's demand for personalized medicine continues to increase, the customization capabilities of CNC machining will be more fully utilized. According to the individual differences of patients, unique medical devices can be manufactured to provide patients with more accurate and effective treatment. In general, the application of precision CNC machining in the medical industry has become an important force in promoting the advancement of medical technology. In the face of ever-changing market demands and technological challenges, enterprises and industries should continue to innovate and develop to make greater contributions to human health. I believe that in the future, with the continuous advancement of technology, precision CNC machining will create more miracles in the medical field and bring more benefits to people's healthy lives.

Share:

Sintering Method and Characteristic Application of Silicon Carbide Products

What is a Powder Metallurgy Bearing?