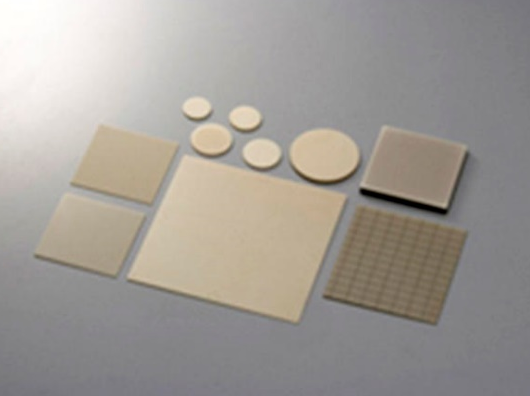

Aluminum Nitride

● High thermal conductivity (about 320 w/m, K), close to BeO and SiC, Al2O3 is five times more

● Thermal expansion coefficient (4.5×10-6℃) and Si (3.5-4×10-6℃) and GaAs (6×10-6℃);

● Excellent electrical properties, dielectric constant, dielectric loss and volume resistivity and dielectric strength);

● Good mechanical performance, bending strength higher than that of Al2O3 and BeO ceramic, can under the normal pressure sintering;

● Good light transmission characteristics;

● Non-toxic

Metal injection moulding of complex shaped parts

MIM technology enables the production of complex shaped parts according to the same manufacturing principle as plastic injection moulding. We inject a mixture of a metallic material with a plastic binder. This is followed by a debinding process in which the plastic is eliminated from the workpiece. Finally, the mechanical properties of the material are restored during sintering.

● Maximum length: 150mm

● Maximum weight: 120 grams

● Thickness: from 0.5 mm

● Opening: from 0.5 mm

● Minimum radius: 0.10 mm

● General roughness: Ra > = 0.4

Tolerances:

● 1 to 6 mm +/- 0.04 mm

● 6 to 12 mm +/- 0.05 mm

● 12 to 25 mm +/- 0.08 mm

● 25 to 50 mm +/- 0.10 mm

● Materials: Stainless steel (17-4PH, AISI 304L/316L, etc.), iron-nickel alloys (FeNi2, FeNi8, etc.), magnetic iron compounds, titanium, steel.

● Other materials are available on request.

● Quantity: from sample to mass production 500 pcs onwards

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays and weekends.

Customer Support

Your satisfaction is our priority.

We offer comprehensive Lifetime Technical Support and Warranty Services.

Contact Us

WhatsApp: +86 180 0255 3024

Email: market@mim-supplier.com

Shipping Information

We usually send samples to you via DHL FedEx or UPS.

Bulk goods will be shipped by sea to save shipping costs

FAQ’s

What materials do you provide?

We offer a wide range of materials for powder metallurgy.

MIM: 304 316 420 17-4 Stainless Steel, TC4 TA2 Titanium Alloys, AISI 310S Nickel-Chromium-Iron Alloys

CIM Process: Zirconia, Alumina, Silicon Nitride, Silicon Carbide, and Aluminum Nitride

Our R&D team can develop customized materials to meet your specific application requirements.