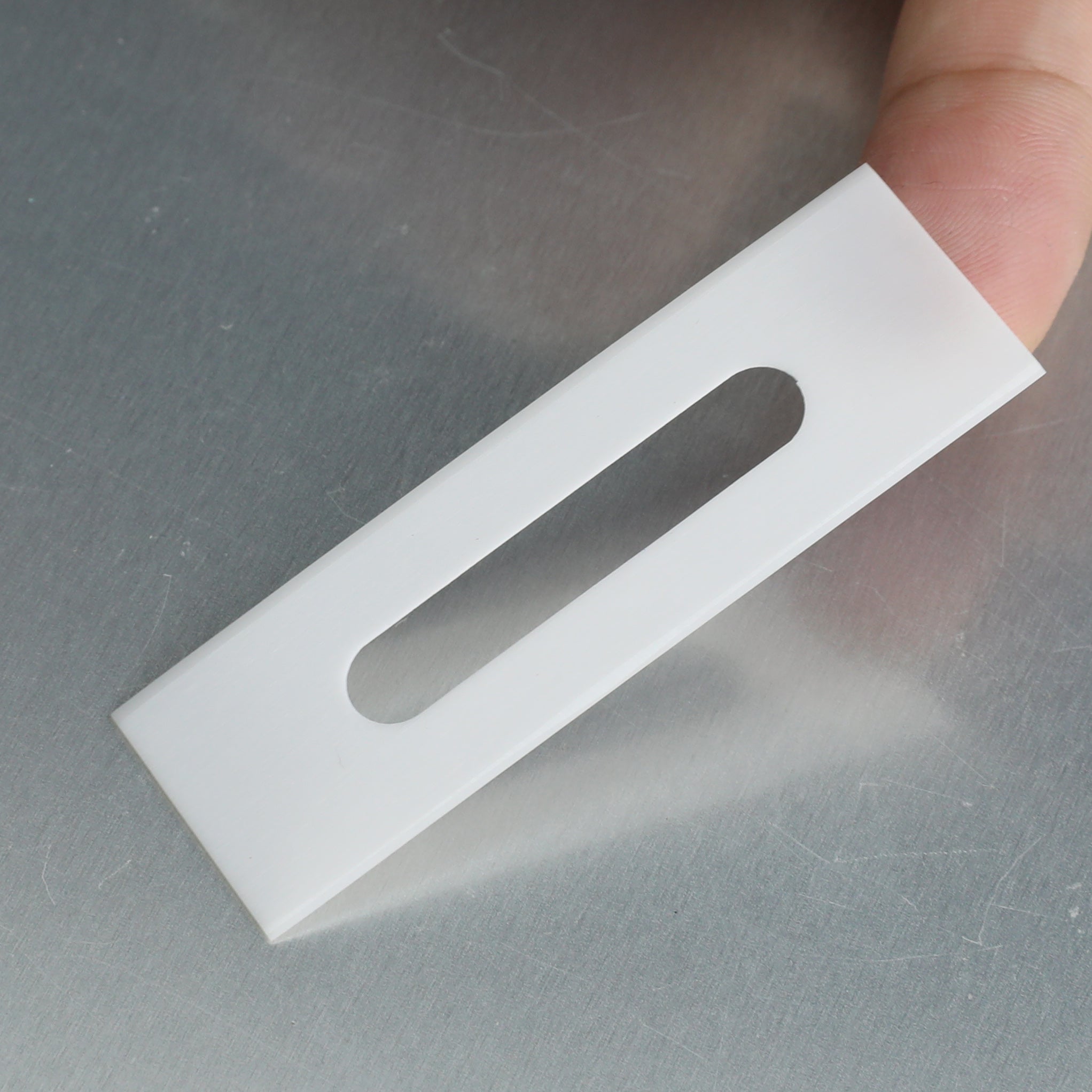

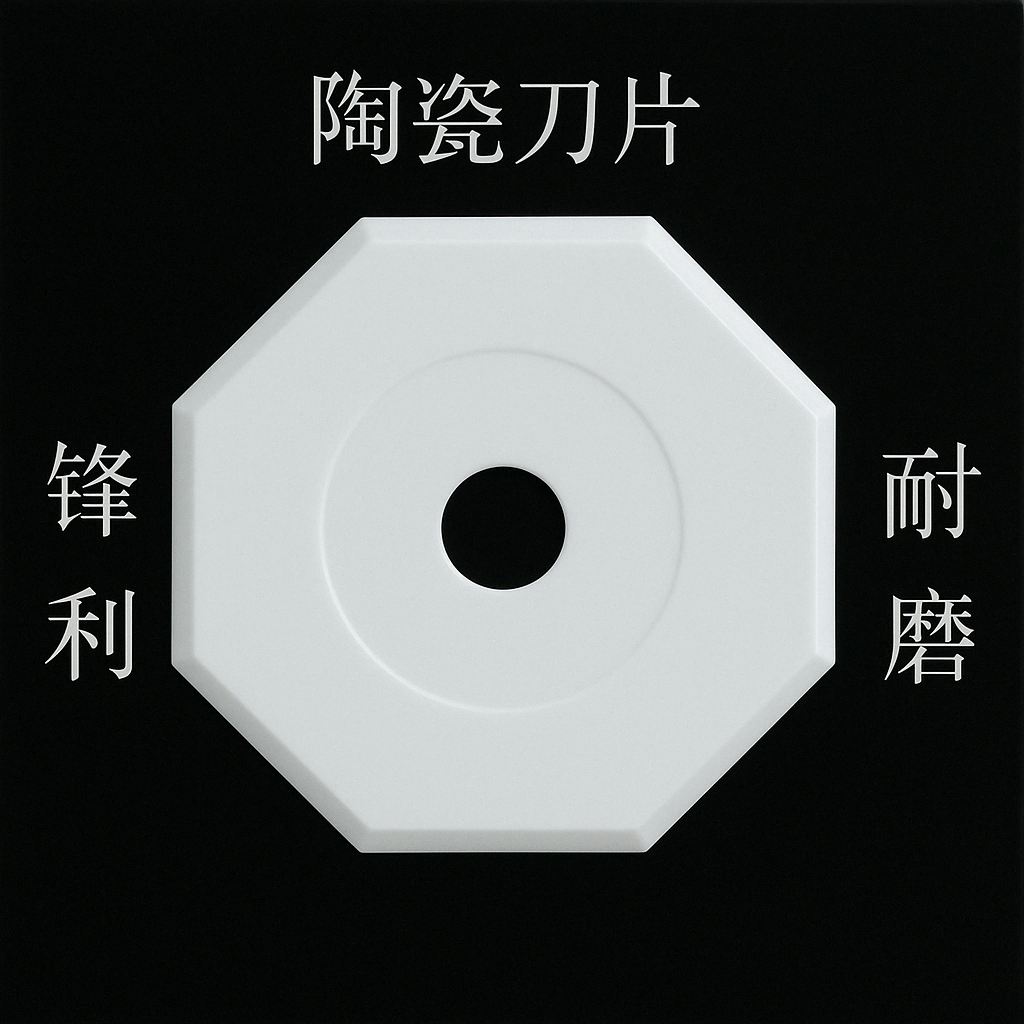

Ceramic Square Blade for Medical Equipment Sharp Wear-Resistant

Product Description: Our precision ceramic blades are designed for high-performance applications in medical and industrial environments. Made from advanced ceramic materials such as zirconia and alumina, these blades provide excellent sharpness, durability, and resistance to wear, making them ideal for cutting and precision tasks in fields like medical device manufacturing, laboratory applications, and precision engineering.

Key Features:

-

Exceptional Sharpness: Our ceramic blades are finely honed to ensure ultra-sharp edges, allowing for precise cutting and reduced wear on the material being cut. This is crucial for applications that require high accuracy, such as in surgical tools or laboratory equipment.

-

Durable and Wear-Resistant: Made from tough, high-performance ceramics, these blades exhibit excellent resistance to abrasion and wear, ensuring consistent performance over a long service life, even under harsh conditions.

-

Biocompatibility: Our ceramic blades are crafted from biocompatible materials, making them suitable for use in medical and healthcare applications where safety and compliance with industry standards are critical.

Materials and Manufacturing Process:

-

High-Quality Materials: The blades are made from zirconia (ZrO2) or alumina (Al2O3), both of which are known for their superior mechanical properties and resistance to corrosion, ensuring the blades maintain their integrity and sharpness.

-

Precision Manufacturing: Each blade is manufactured using advanced precision machining techniques, including diamond grinding and high-temperature sintering, to achieve the required sharpness and durability for cutting-edge applications.

Surface Treatment:

-

Polished and Smooth Finish: The blades are polished to a high-gloss finish, reducing friction and preventing material buildup, which enhances cutting performance and longevity.

-

Corrosion-Resistant Coatings: For specific applications, additional coatings can be applied to further improve resistance to corrosion and enhance biocompatibility, ensuring the blades perform reliably in sterile or corrosive environments.

Our ceramic blades are perfect for industries where precision, durability, and high-quality performance are paramount. Whether used for surgical tools, laboratory instruments, or precision cutting tasks, they offer unmatched reliability and efficiency.

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays and weekends.

Customer Support

Your satisfaction is our priority.

We offer comprehensive Lifetime Technical Support and Warranty Services.

Contact Us

WhatsApp: +86 180 0255 3024

Email: market@mim-supplier.com

Shipping Information

We usually send samples to you via DHL FedEx or UPS.

Bulk goods will be shipped by sea to save shipping costs

FAQ’s

What materials do you provide?

We offer a wide range of materials for powder metallurgy.

MIM: 304 316 420 17-4 Stainless Steel, TC4 TA2 Titanium Alloys, AISI 310S Nickel-Chromium-Iron Alloys

CIM Process: Zirconia, Alumina, Silicon Nitride, Silicon Carbide, and Aluminum Nitride

Our R&D team can develop customized materials to meet your specific application requirements.