Stainless Steel Injection Molding for Electronics, Bioimplants and Wearable Devices

High-strength steel injection molded products have excellent performance, achieving stable mass production and achieving mechanical properties of yield strength greater than 1600MPa, tensile strength greater than 1700MPa, and elongation greater than 5%.

When the elongation requirements of molded products are reduced (2-3%), the yield strength can be pushed up to more than 1700MPa, and the tensile strength can be pushed up to more than 1900MPa.

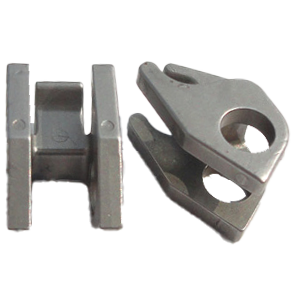

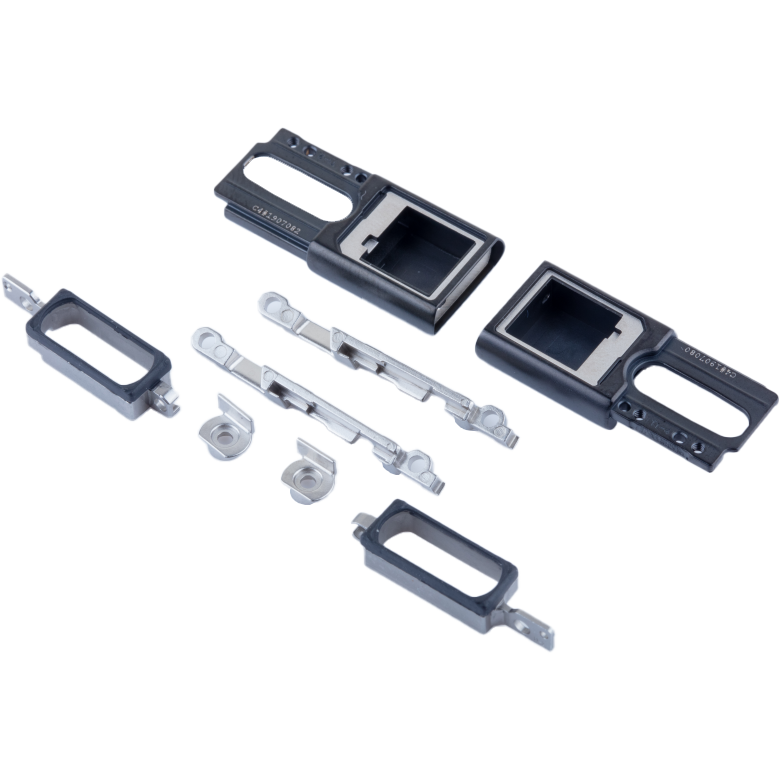

Steel injection molded products are suitable for applications with high load and high wear resistance, such as folding screen mobile phone shaft parts. Under the same strength requirements, the parts can be designed to be thinner.

Our high nitrogen steel uses nitrogen instead of nickel to stabilize austenite. Traditional austenitic stainless steel has low strength and poor biocompatibility. Our solution is to use nitrogen instead of nickel to stabilize the austenite structure. Such steel injection molded products have good ductility, high corrosion resistance, non-magnetic and exquisite appearance.

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays and weekends.

Customer Support

Your satisfaction is our priority.

We offer comprehensive Lifetime Technical Support and Warranty Services.

Contact Us

WhatsApp: +86 180 0255 3024

Email: market@mim-supplier.com

Shipping Information

We usually send samples to you via DHL FedEx or UPS.

Bulk goods will be shipped by sea to save shipping costs

FAQ’s

What materials do you provide?

We offer a wide range of materials for powder metallurgy.

MIM: 304 316 420 17-4 Stainless Steel, TC4 TA2 Titanium Alloys, AISI 310S Nickel-Chromium-Iron Alloys

CIM Process: Zirconia, Alumina, Silicon Nitride, Silicon Carbide, and Aluminum Nitride

Our R&D team can develop customized materials to meet your specific application requirements.