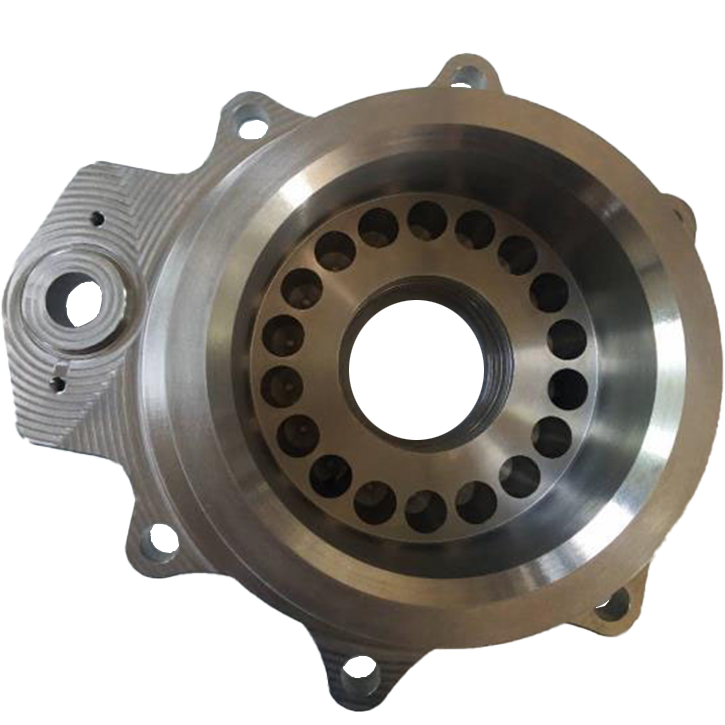

Titanium Injection Molding for Aerospace, Space Rockets, and Aircraft Engine Parts

We can process different types of titanium injection molding products according to different standards or drawing requirements. The manufacturing process follows the national standards GB/T16598, GB/T25137, GJB2744A, HG 20593~HG20601 to produce pure titanium, titanium alloy processing parts and titanium alloy flanges. Our titanium injection factory stocks many titanium ingots and blanks with short lead times.

The final product is subjected to 100% ultrasonic flaw detection for each product in accordance with AMS2631 or GB/T 5193 to ensure that there are no defects inside the product. Visual inspection and penetrant testing of the surface of the titanium ring are performed to ensure that there are no cracks, black spots or other defects. MIM Supplier can provide Separate laboratory physical and chemical test reports, test items can be customized according to customer requirements.

We can also provide penetrant testing, chemical composition, mechanical properties, hardness, and metallographic analysis.

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays and weekends.

Customer Support

Your satisfaction is our priority.

We offer comprehensive Lifetime Technical Support and Warranty Services.

Contact Us

WhatsApp: +86 180 0255 3024

Email: market@mim-supplier.com

Shipping Information

We usually send samples to you via DHL FedEx or UPS.

Bulk goods will be shipped by sea to save shipping costs

FAQ’s

What materials do you provide?

We offer a wide range of materials for powder metallurgy.

MIM: 304 316 420 17-4 Stainless Steel, TC4 TA2 Titanium Alloys, AISI 310S Nickel-Chromium-Iron Alloys

CIM Process: Zirconia, Alumina, Silicon Nitride, Silicon Carbide, and Aluminum Nitride

Our R&D team can develop customized materials to meet your specific application requirements.