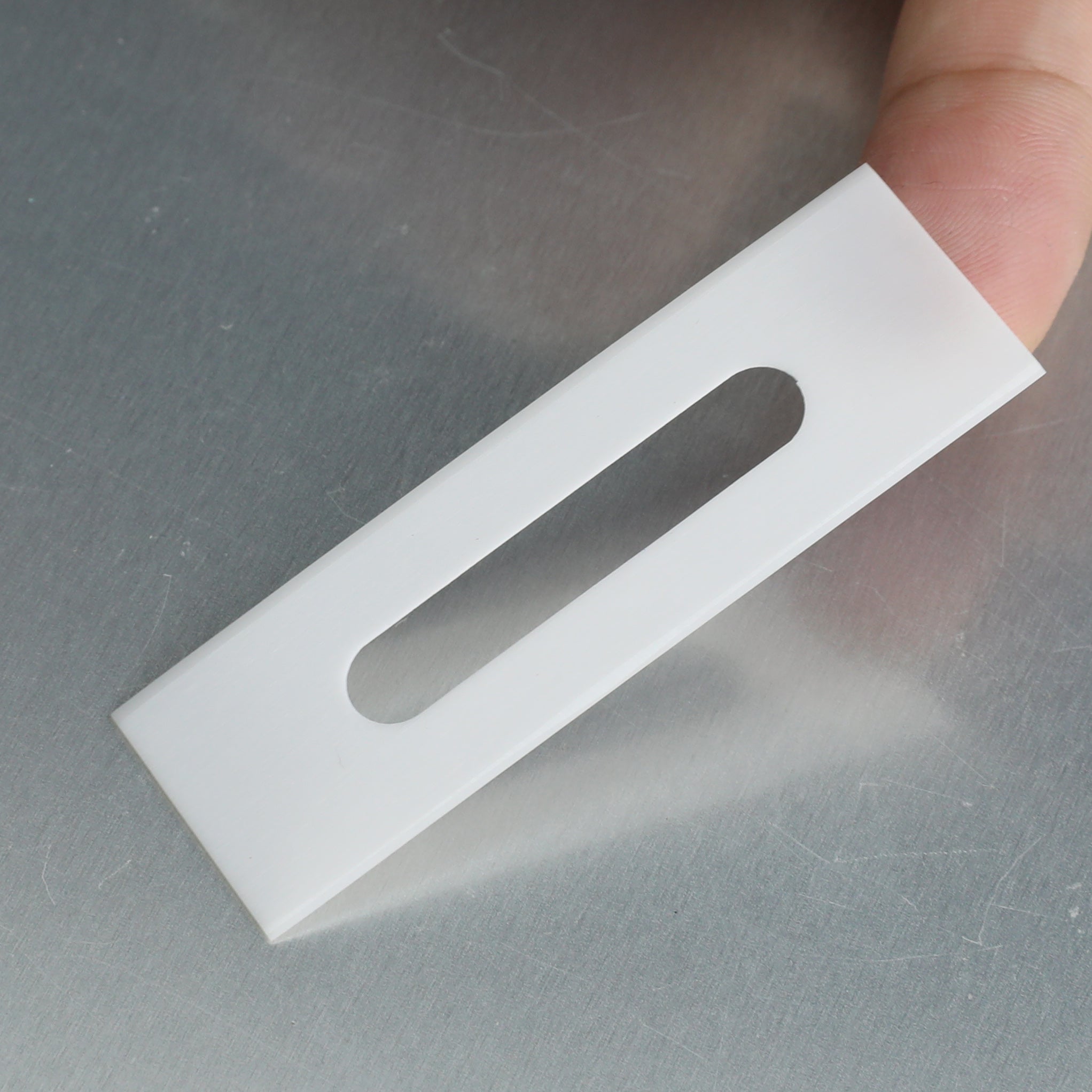

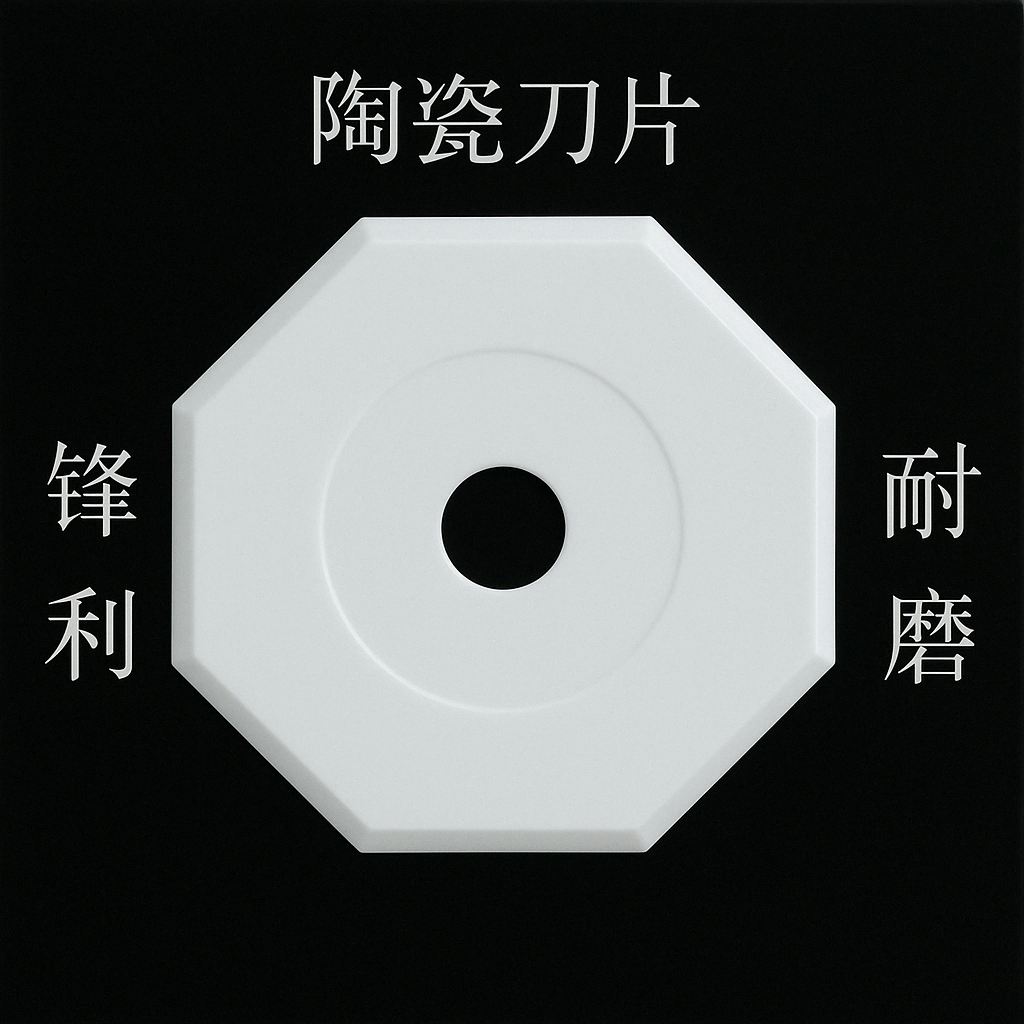

Hoja cuadrada de cerámica para equipos médicos, afilada y resistente al desgaste.

Descripción del producto: Nuestras hojas de cerámica de precisión están diseñadas para aplicaciones de alto rendimiento en entornos médicos e industriales. Fabricadas con materiales cerámicos avanzados como zirconio y alúmina, estas hojas ofrecen un excelente filo, durabilidad y resistencia al desgaste, lo que las hace ideales para tareas de corte y precisión en campos como la fabricación de dispositivos médicos, aplicaciones de laboratorio e ingeniería de precisión.

Características principales:

-

Afilado excepcional: Nuestras hojas de cerámica están finamente afiladas para garantizar filos ultraafilados, lo que permite un corte preciso y reduce el desgaste del material. Esto es crucial para aplicaciones que requieren alta precisión, como en instrumental quirúrgico o equipos de laboratorio.

-

Duraderas y resistentes al desgaste: fabricadas con cerámica resistente y de alto rendimiento, estas hojas exhiben una excelente resistencia a la abrasión y al desgaste, lo que garantiza un rendimiento constante durante una larga vida útil, incluso en condiciones difíciles.

-

Biocompatibilidad: Nuestras hojas de cerámica están fabricadas con materiales biocompatibles, lo que las hace adecuadas para su uso en aplicaciones médicas y de atención médica donde la seguridad y el cumplimiento de los estándares de la industria son fundamentales.

Materiales y proceso de fabricación:

-

Materiales de alta calidad: Las hojas están hechas de zirconia (ZrO2) o alúmina (Al2O3), ambas conocidas por sus propiedades mecánicas superiores y resistencia a la corrosión, lo que garantiza que las hojas mantengan su integridad y nitidez.

-

Fabricación de precisión: cada hoja se fabrica utilizando técnicas avanzadas de mecanizado de precisión, incluido el rectificado de diamante y la sinterización a alta temperatura, para lograr la nitidez y la durabilidad necesarias para aplicaciones de vanguardia.

Tratamiento de superficie:

-

Acabado pulido y suave: las hojas están pulidas hasta obtener un acabado de alto brillo, lo que reduce la fricción y evita la acumulación de material, lo que mejora el rendimiento de corte y la longevidad.

-

Recubrimientos resistentes a la corrosión: para aplicaciones específicas, se pueden aplicar recubrimientos adicionales para mejorar aún más la resistencia a la corrosión y mejorar la biocompatibilidad, garantizando que las hojas funcionen de manera confiable en entornos estériles o corrosivos.

Nuestras hojas de cerámica son perfectas para industrias donde la precisión, la durabilidad y el alto rendimiento son primordiales. Ya sea para herramientas quirúrgicas, instrumental de laboratorio o tareas de corte de precisión, ofrecen una fiabilidad y eficiencia inigualables.

Si tiene alguna pregunta, siempre puede contactarnos. Le responderemos lo antes posible, dentro de las 24 horas, los días hábiles y los fines de semana.

Atención al cliente

Su satisfacción es nuestra prioridad.

Ofrecemos soporte técnico integral de por vida y servicios de garantía .

Contáctenos

WhatsApp: +86 180 0255 3024

Correo electrónico: market@mim-supplier.com

Información de envío

Generalmente le enviamos muestras a través de DHL FedEx o UPS.

Las mercancías a granel se enviarán por mar para ahorrar costes de envío.

Preguntas frecuentes

¿Qué materiales proporcionas?

Ofrecemos una amplia gama de materiales para pulvimetalurgia.

MIM: acero inoxidable 304 316 420 17-4, aleaciones de titanio TC4 TA2, aleaciones de níquel-cromo-hierro AISI 310S

Proceso CIM: Zirconia, Alúmina, Nitruro de Silicio, Carburo de Silicio y Nitruro de Aluminio

Nuestro equipo de I+D puede desarrollar materiales personalizados para satisfacer los requisitos de su aplicación específica.