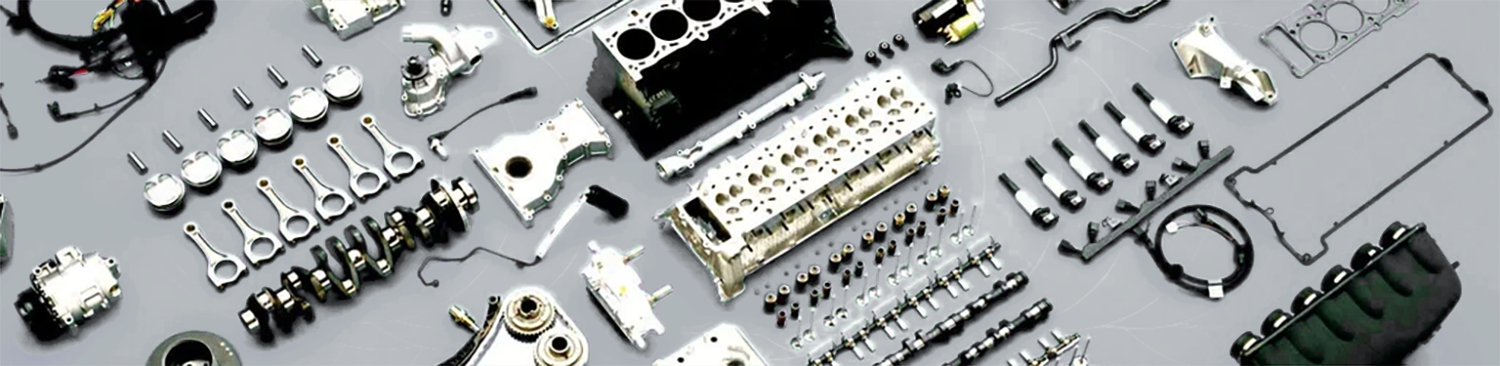

XY-GLOBAL is committed to providing the automotive industry with superior mechanical components and assemblies to match the reliability and performance of your automotive products. We create value-added solutions for our automotive industry customers through collaborative relationships, engineering expertise and innovation.

XY-GLOBAL is committed to providing the automotive industry with superior mechanical components and assemblies to match the reliability and performance of your automotive products. We create value-added solutions for our automotive industry customers through collaborative relationships, engineering expertise and innovation.

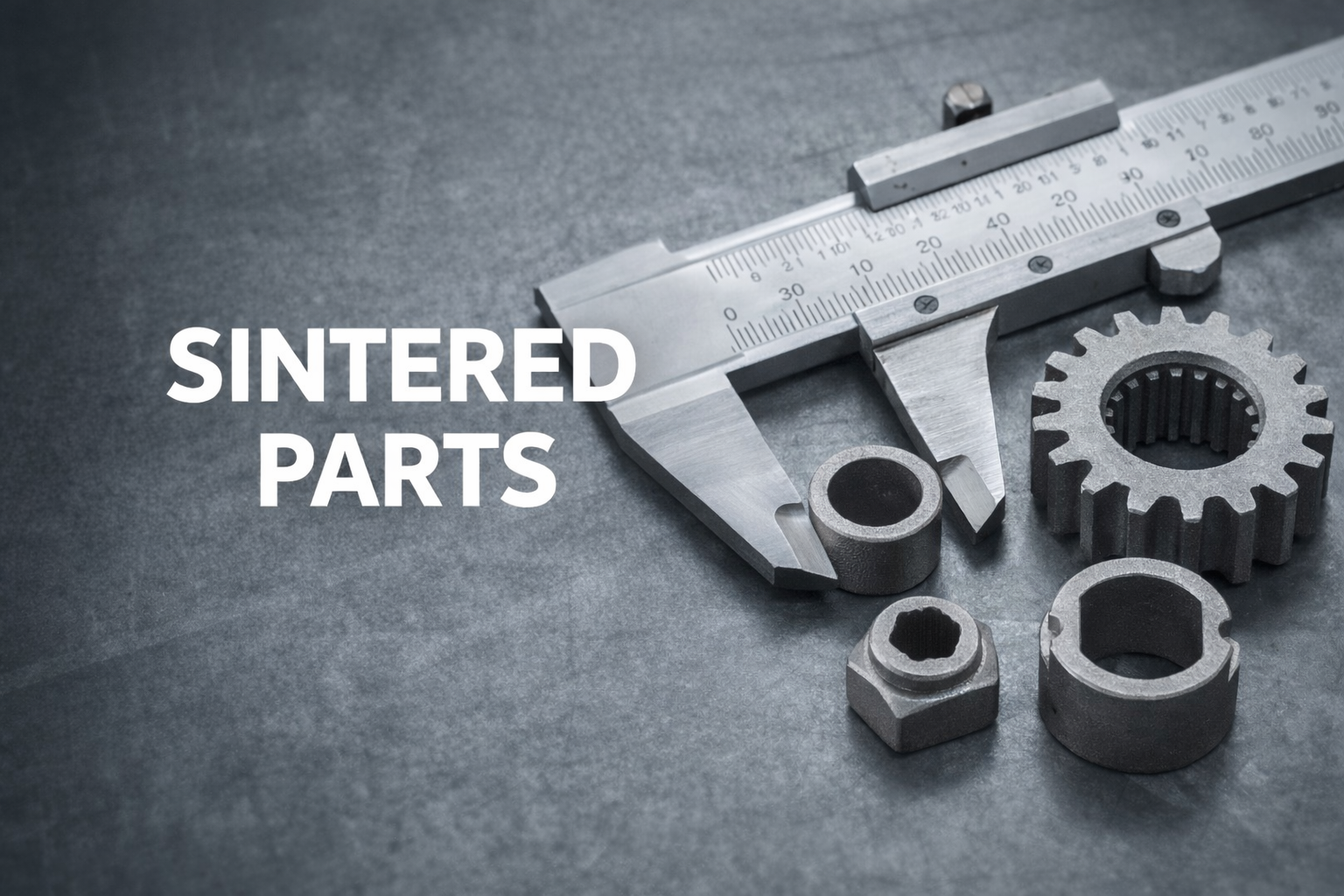

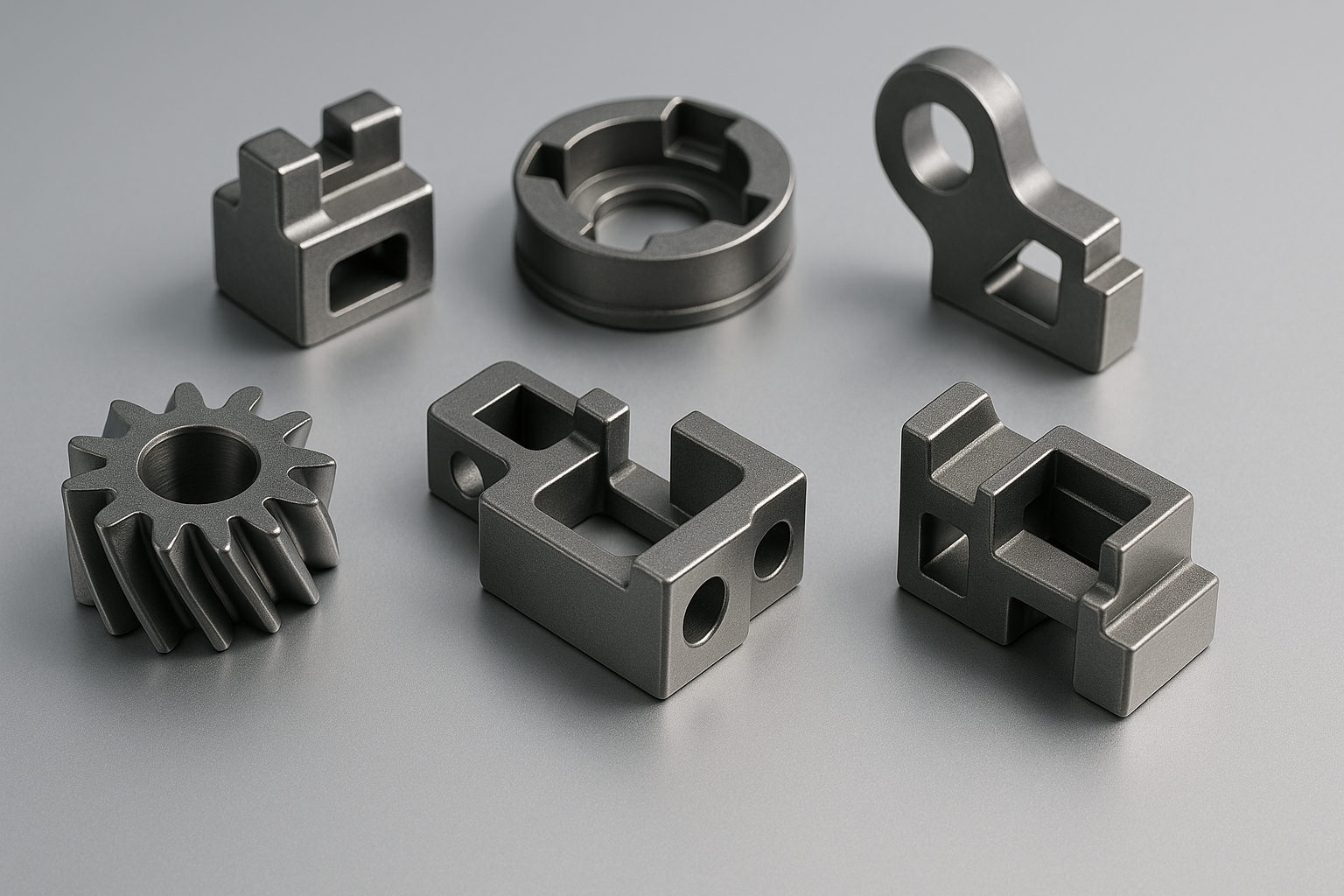

With the continuous advancement of technology, the automotive field is constantly evolving and innovating. And the metal powder metallurgy process has become an integral part of modern automotive production. Metal powder metallurgy process is an efficient and energy-saving method for manufacturing metal parts. Its technical feature is that the metal powder is mixed with binder through the powder metallurgy process and then pressed, sintered, precision formed and other processes to produce parts with complex shapes, so as to achieve light weight, high strength and high precision.

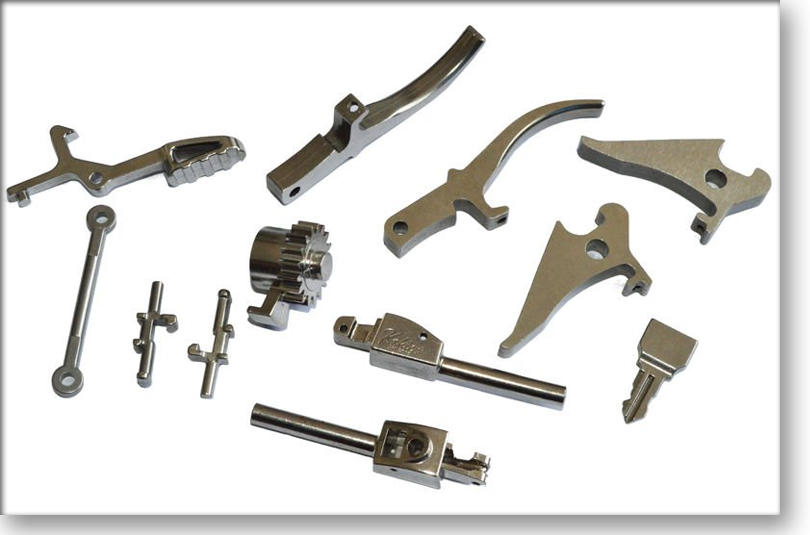

In automobile manufacturing, metal powder metallurgy process is widely used to manufacture various auto parts with high strength, wear resistance, corrosion resistance and high temperature materials, such as gears, clutches, crankshafts, shock absorbers, valve seats, etc. The use of metal powder metallurgy process can greatly reduce the cost of automotive parts, and can produce more lightweight, high-strength parts. In the context of continuous promotion of automotive lightweighting, the application of metal powder metallurgy process is very promising.

Compared with traditional automotive parts manufacturing methods, the metal powder metallurgy process has the following advantages:

1. Highly customizable: It has a wide range of application because it can be customized according to the different shapes, sizes, materials and other characteristics of the parts.

2. Raw material saving: In the powder metallurgy process, the raw material can be fully utilized, reducing the scrap rate and material loss.

3. Lightweight: Auto parts manufactured by metal powder metallurgy process have lower density than traditional process, so it can achieve lighter weight design while ensuring strength, reducing the weight of the whole car and improving fuel efficiency.

4. reduce the process: metal powder metallurgy process manufacturing automotive parts can be achieved through a single molding, reducing the processing process and improving production efficiency.

In conclusion, metal powder metallurgy process has a wide range of application prospects in the field of automotive manufacturing. Through continuous innovation and improvement of technology, metal powder metallurgy process can better meet the demand for high-precision, high-performance, high-reliability and low-cost parts in the field of automotive manufacturing. At the same time, metal powder metallurgy process can also reduce material waste and environmental pollution, which is in line with the concept of sustainable development of automotive manufacturing industry.

In the future, with the continuous development of automotive manufacturing technology and material science, the application prospect of metal powder metallurgy process in automotive field will be more and more broad. It is expected that in the next few years, with the continuous improvement of metal powder metallurgy technology, more high-quality, high-performance, low-cost automotive parts will appear, which will further promote the progress and development of the automotive manufacturing industry.

Meanwhile, with the rapid growth of new energy vehicle market, metal powder metallurgy process will also provide more solutions for new energy vehicles such as electric vehicles and hybrid vehicles. For example, motor rotors made by metal powder metallurgy technology can improve the efficiency and performance of electric vehicles and have a longer service life.

In conclusion, the application of metal powder metallurgy process in the field of automotive manufacturing continues to expand and deepen, and will become one of the important technologies in the automotive manufacturing industry. With the continuous innovation and development of technology, it is believed that metal powder metallurgy process will bring more opportunities and challenges for automotive manufacturing.

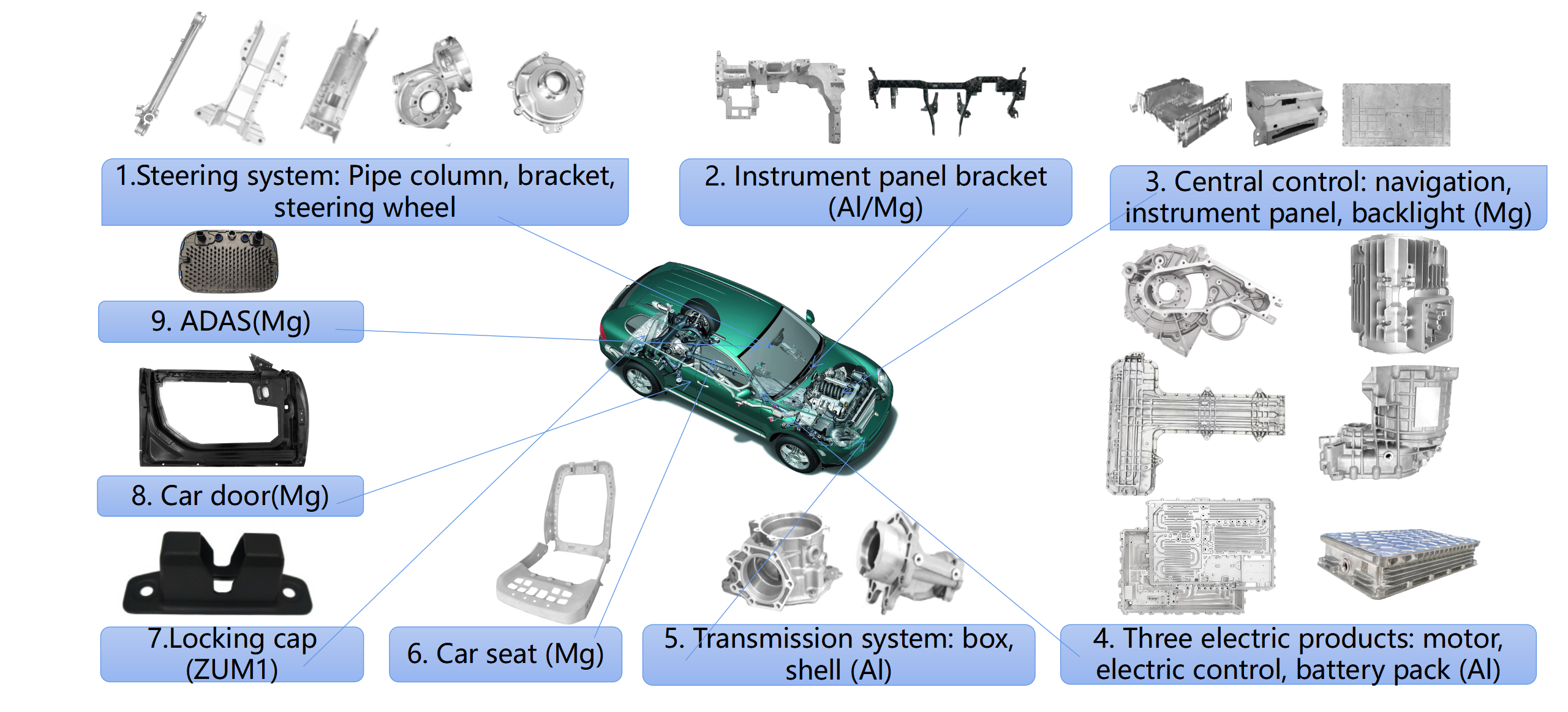

We work with automakers to help them stay ahead of the curve. We enable them to accelerate prototyping so that they can quickly assess the feasibility of new components and go through the Production Parts Approval Process (PPAP). Then, when a part enters the production stage, we can quickly move up to mass production at almost any scale. Parts and assemblies that support the following applications:

● Steering system: Pipe column, bracket, steering wheel

● Instrument panel bracket (Al/Mg)

● Central control: navigation, instrument panel, backlight (Mg)

● Three electric products: motor, electric control, battery pack (Al)

● Transmission system: box, shell (Al)

● Car seat (Mg)

● Locking cap (ZUM1)

● Car door(Mg)

● ADAS(Mg)

Share:

Industrial Field Designed by Metal Powder Injection Molding Service with Best Cost from MIM TOP

Dispositivi e apparecchiature mediche tramite MIM per l'industria medica e dentale dal produttore cinese con un prezzo competitivo