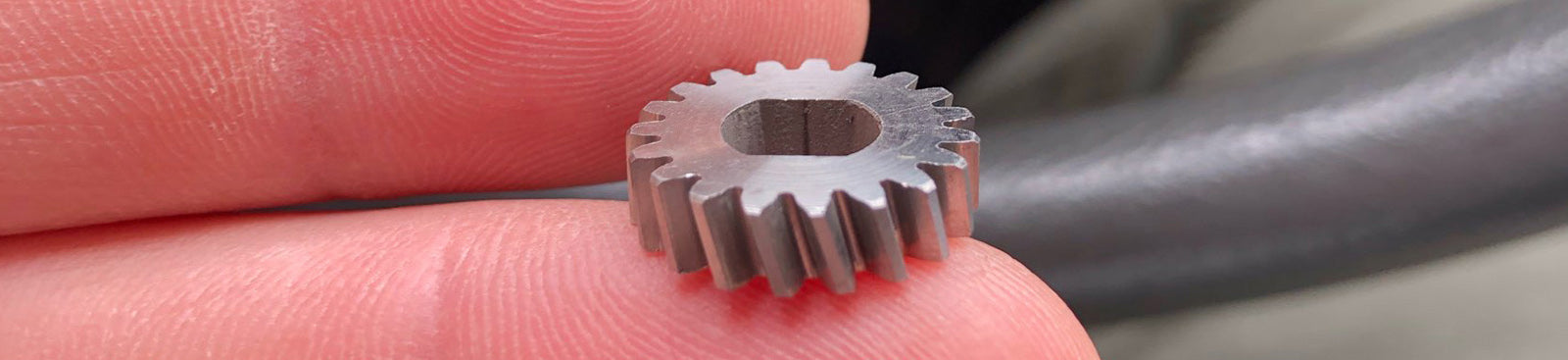

Let's review the production process of tiny gears. In 1973, the oil crisis broke out in Japan. The government advocated that enterprises across the country reduce energy consumption. Motoo Matsuura, general manager of Japan Shuken Co., Ltd., a small gear-producing enterprise in Aichi Prefecture, saw new business opportunities from this crisis: energy saving will become a trend. He felt that all products would become smaller and smaller, and to reduce the size of products, the components of the products must first be reduced.

At that time, the smallest metal gear that could be produced in the same industry in Japan weighed about one hundredth of a gram, and this gear was often used in watches. Motoo Matsuura bought more than 50 Seiko and Citizen watches and disassembled them one by one to see if they could be replaced with plastic gears to produce smaller gears.

In 1986, Shuken finally successfully developed a super-small rubber gear weighing one thousandth of a gram. Ricoh, Casio and other watch companies took the initiative to come to the door and signed cooperation agreements with Shuken Co., Ltd. Motoo Matsuura was not satisfied with this. Soon, a gear weighing one ten-thousandth of a gram was successfully developed by Shuken. Some Japanese craftsmen said that if Shuken could produce a gear of one hundred thousandth of a gram, it would be a real success. "Okay, let's jump again and produce one hundred thousandth of a gram," Matsuura Motoo accepted the challenge.

In May 1988, the gear of one hundred thousandth of a gram was born. The famous Swiss Swatch Watch Group. British auto parts manufacturer EMI and other companies signed agreements with Shuken and requested orders. Since there was no competitor, Shuken basically did not give buyers a chance to bargain. After that, the gear of one hundred thousandth of a gram was gradually used in miniature cameras. Video cameras and special mobile phones and computers, and then they were purchased in large quantities by governments of various countries and used in mini reconnaissance aircraft to reduce the weight of the aircraft and facilitate operation.

In August 2002, Shuken produced a gear of one millionth of a gram. It is called a powder gear, with a diameter of 0.15 mm and a maximum width of 0.08 mm. The entire gear area is about the same as the cross-sectional area of a hair. However, even on such a small gear, there are 5 small teeth evenly distributed, which can operate like ordinary gears. It only takes 3.5 seconds to produce 4 such gears at a time. As Matsuura expected, this powder gear has now been installed by doctors in several top hospitals in the United States on the front section of artificial fiber blood vessels to clean the cerebral blood vessels of patients with cerebral infarction, becoming an important medical device for saving lives.

The development of the manufacturing of micro-pinion gears has not stopped there. In the continuous development of practical society.

Manufacturing method of micro gears

In terms of drive motors, micro motors with a rotor diameter of 0.5mm and an outer diameter of several millimeters have been manufactured. However, due to the high speed and low torque of this micro motor, in order to fully exert its performance, a micro reducer with a transmission ratio of several hundred is required between the motor and the load (actuator). Among various transmission mechanisms, gear transmission is the most commonly used. Therefore, in order to miniaturize the reducer, it is necessary to miniaturize the gear.

Hobbing processing

Gears are usually cut on a hobbing machine using a hob. When hobbing micro gears (less than m0.1), the tooth shape of the hob must be micro-machined. Because the tooth shape is small, in addition to the hob tooth shape error, the hob's aperture runout, end face runout, pitch and other errors will have a great impact on the accuracy of the micro gear. The precision and rigidity of the gear hobbing machine, workpiece spindle, tool spindle, workpiece indexing mechanism and workpiece fixture used for processing, as well as the installation precision of the hob and workpiece, will affect the manufacturing precision of micro gears. Therefore, it is necessary to improve the overall comprehensive precision of the manufacturing system. On this basis, by selecting easy-to-cut materials, it is easier to mass-produce micro gears with the same modulus and different varieties.

Injection molded plastic gears

Plastic gears processed by injection molding are mostly used for gears used under lighter loads such as office machines and household appliances because they can be mass-produced in a short time. In recent years, with the continuous improvement of injection molding technology and the continuous improvement of injection molding material performance, the precision of injection molded gears has also been greatly improved. The precision of injection molded gears and injection molding technology are both important factors affecting the injection molding method. When making molds, wire cutting and electrospark machining are mainly used. However, due to the influence of factors such as the wire diameter used and the discharge gap of the molding electrode, the improvement of the precision of micro gear molds is limited. The mold can also be manufactured by electroforming. The reference gear used for electroforming can be improved by cutting or grinding. The reference gear can be thickened by electroplating.

Metal sintering manufacturing method

The sintered metal gear (powder metallurgy gear) formed by high-pressure molding of metal powder in the mold and high-temperature sintering and curing has higher mechanical strength than plastic gears and is used under medium load conditions. The mold molding method is suitable for mass production. However, after the mold is formed, it is sintered at high temperature and deforms greatly. Therefore, in order to achieve the necessary accuracy, the gear must be fine-machined after sintering. Due to the small tooth shape, the fine machining of micro gears is relatively difficult, and the metal particles of metal powder are large, which limits the improvement of its shape accuracy and surface finish. If the molding mold adopts the reference gear electrode electrolytic machining method mentioned in the injection molding of plastic gears above, the accuracy of the machined gear may be improved.

Other manufacturing methods

Micro gears can be manufactured by semiconductor manufacturing, photoetching or laser processing. Photoetching can trial-produce micro gears of several tens of microns in size, and broaches can draw internal gears, etc. In the future, the demand for micro gears will increase, and new manufacturing methods and mass production technologies will continue to emerge.

Welcome to our Industry!Our service will definitely satisfy you.

Share:

Micro-Injection Molding Process

Low Alloy Steel Material for Metal Injection - MIM 4605