Knowledge

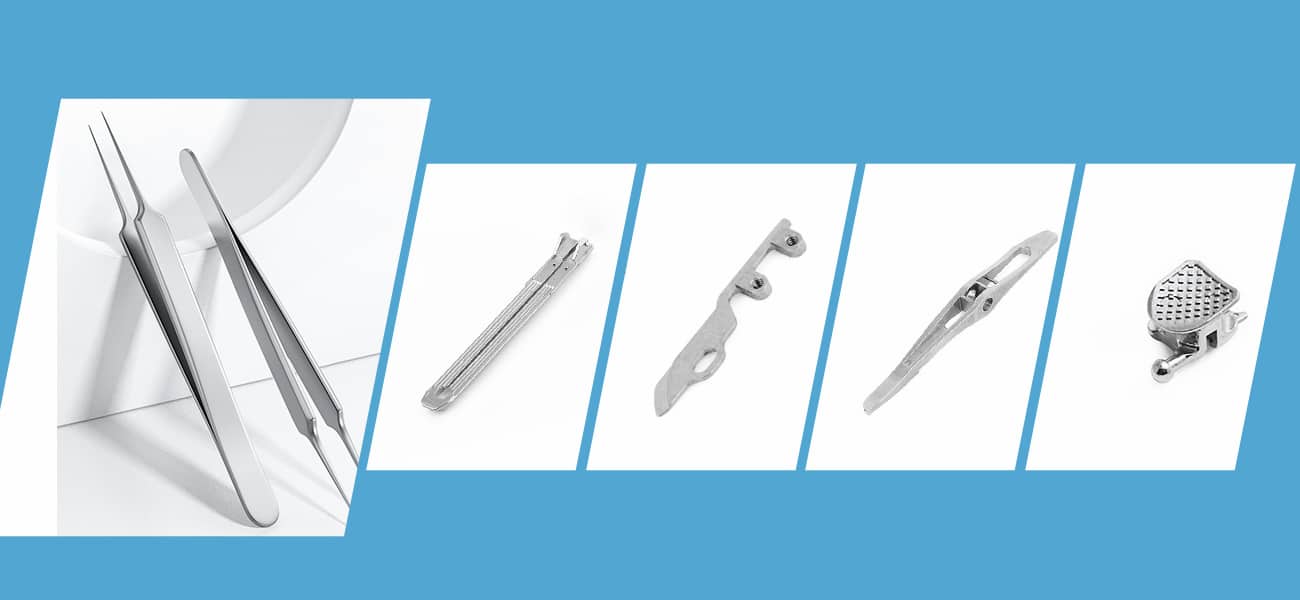

Which Parts Are Suitable for MIM Process?

Advantages of Metal Injection Molding(MIM)

Powder Forging Process - Important Near-Net-Shape Forming Process for Mechanical Parts

Thermal Spraying Ceramic Coating Process and Application

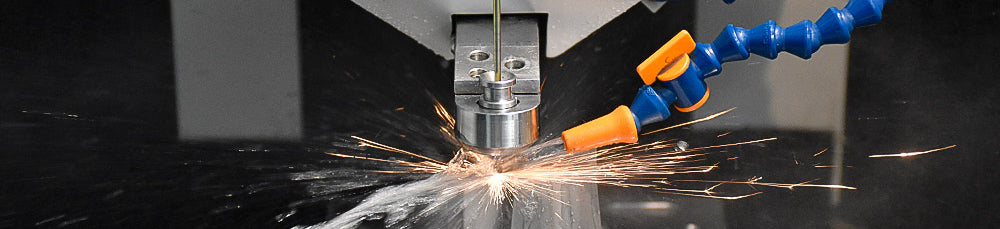

Principle and Application of Electrospark Machining (EDM)

Din Sint-D 32 Din 30910-4 Introduction

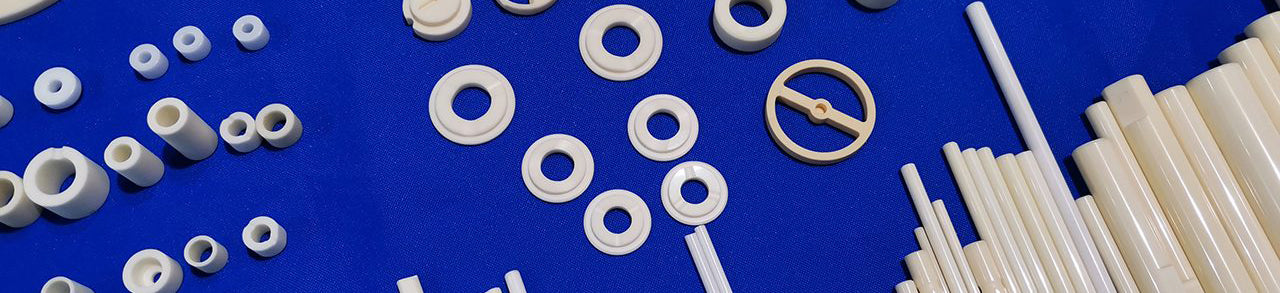

Hot Pressing Sintering Technology for Advanced Ceramics