Knowledge

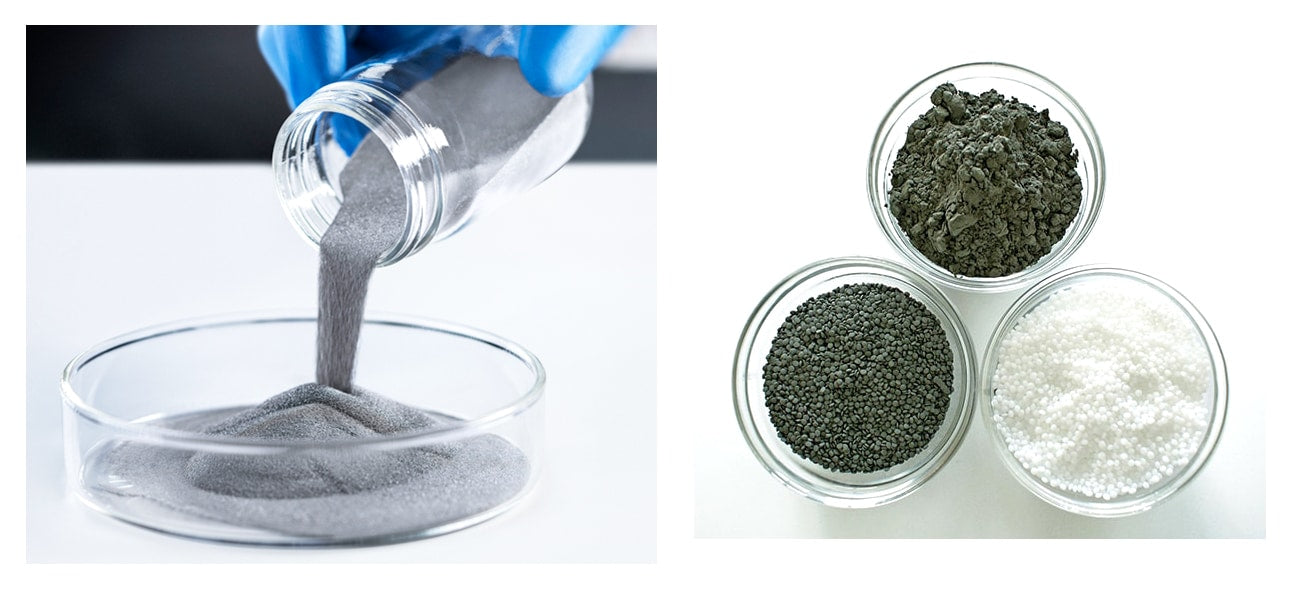

Metal Powder Manufacturing and 3D Printing

Introduction to Powder Metal Casting

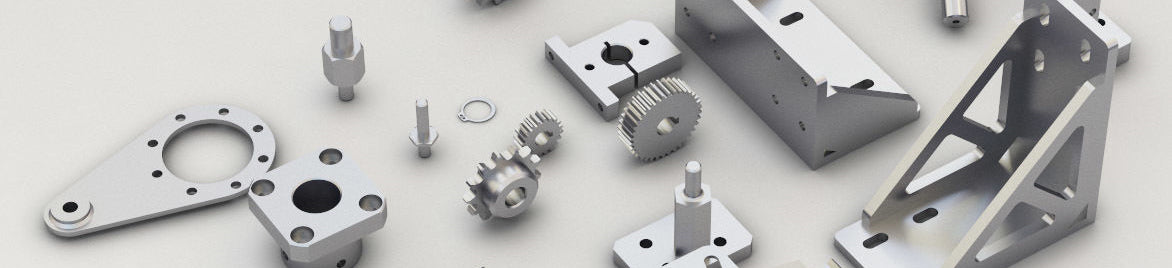

CNC Machining for the Medical Industry: Precision Meets Innovation

Is Powder Metallurgy Expensive?

How μ-Mim Technology Helps Medical Device Development

Tungsten-Copper Injection Molding Applications

Low Alloy Steel Material for Metal Injection - MIM 4605