Knowledge

Din Sint-D 32 Din 30910-4 Introduction

Hot Pressing Sintering Technology for Advanced Ceramics

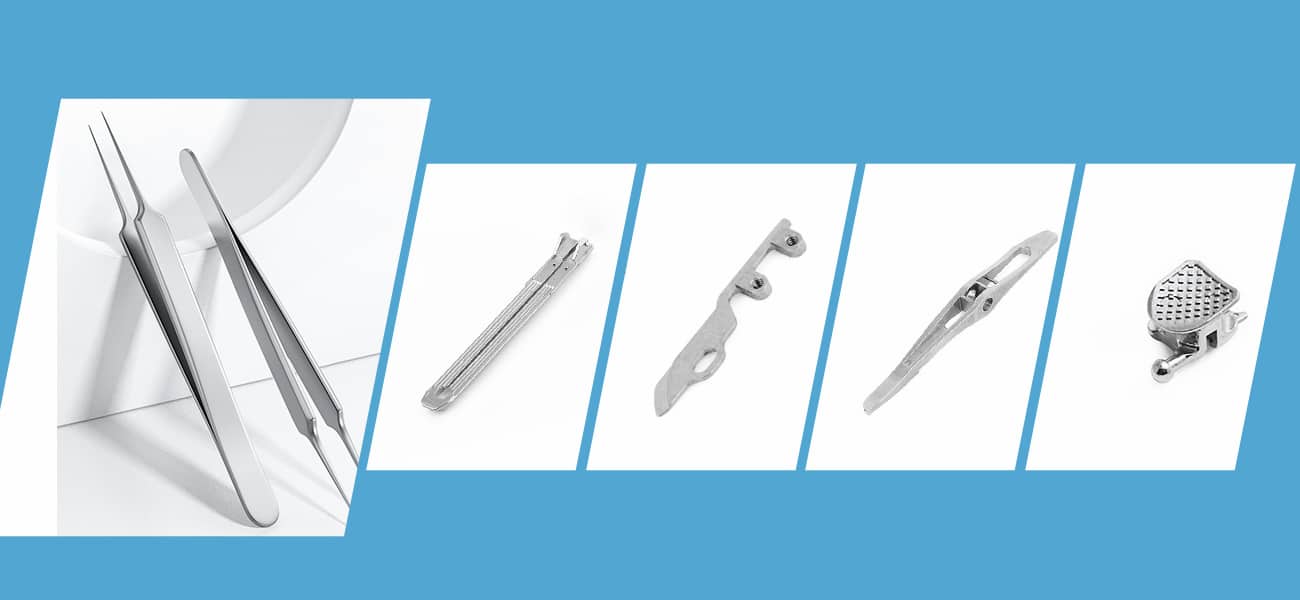

Some Applications of Ceramic Parts in the Semiconductor Field

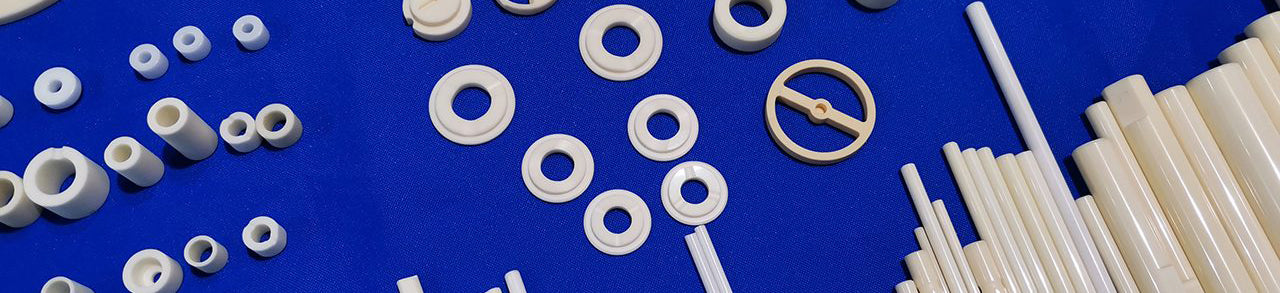

Precision Machining of Ceramic Parts

Metal Injection Molding Tolerances

Carbide Refractory Materials - From Synthesis to Finished Products

Application of Tungsten Alloy in Science and Technology

Custom Ceramic Parts: Precision Solutions for High-Performance Materials

MIM Materials: A Key Choice in Modern Manufacturing