Carbide refers to a binary compound formed by carbon and an element with a smaller or similar electronegativity (except hydrogen). Carbides have a high melting point. Most carbides are obtained by sintering carbon and metals under high temperature vacuum conditions.

Carbide sintering refers to the binary compound generated by high-temperature fusion of carbon and an element with a smaller or similar electronegativity (except hydrogen). Carbides have a high melting point. Most carbides are obtained by sintering carbon and metal under high-temperature vacuum conditions.

There are three methods for carbide sintering:

(1) Direct combination of metal and carbon powder, with a reaction temperature of about 1200~2000℃;

(2) Reaction of metal with carbon-containing gas;

(3) Carbon and oxide reaction (carbon reduction method), that is, a mixture of oxide and carbon is melted and synthesized at high temperature, or in vacuum, hydrogen, inert gas or other reducing atmosphere, at a temperature below the melting point of the oxide, the oxide is reduced with carbon, and a solid phase reaction occurs to synthesize carbide.

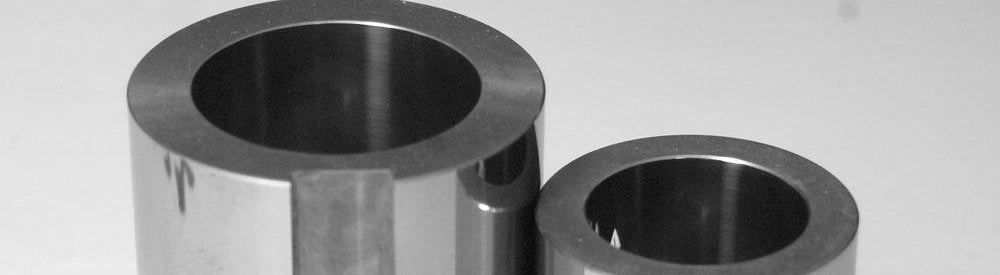

Using the synthesized carbide as raw material, refractory products are manufactured by powder metallurgy process. Carbide refractory materials can be divided into pure carbide materials such as SiC, B4C, Cr3C2 and TaC according to their chemical composition; composite carbide materials such as TiC-WC-TaC, WC-Co, carbide-carbon system and "hypereutectic carbide" materials.

Share:

The Injection Molding of Zirconia Ceramic Structural Parts

Can Carbon Fiber Composites Be Injection Molded?