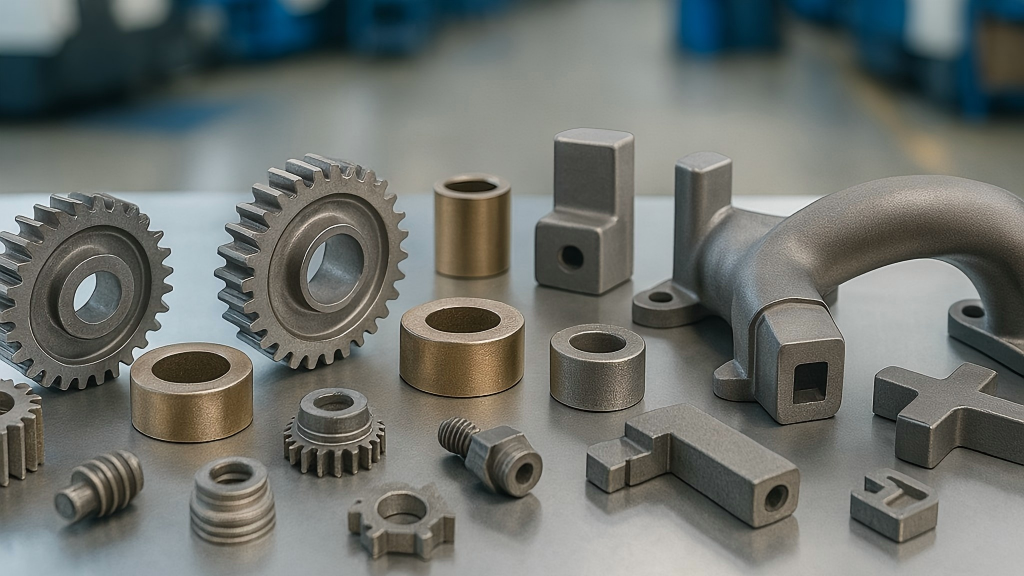

Когда говорят о спекании металлов, обычно представляют себе сложные печи и высокие температуры — и они правы. Но за каждой спечённой шестернёй, кронштейном или разъёмом стоит простая логика: взять металлический порошок, спрессовать его, нагреть до температуры чуть ниже точки плавления, а остальное сделать с помощью диффузии.

Этот процесс превращает мельчайшие частицы в прочную, плотную деталь — без традиционной плавки, ковки или механической обработки.

1. Что такое спекание металлов?

Спекание металлов — это процесс прессования и нагревания металлических порошков для получения цельного изделия. Обычно он включает следующие этапы:

| Этап | Описание | Типичные параметры |

|---|---|---|

| Приготовление порошка | Смешивание металлических порошков со смазочными материалами или связующими | Размер частиц 10–100 мкм |

| Уплотнение | Прессование порошка в форму с помощью штампов | Давление: 400–800 МПа |

| Спекание | Нагревание ниже точки плавления для сплавления частиц | Температура: 1100–1350 °C для сталей |

| Постобработка | Механическая обработка, калибровка или инфильтрация для точности | Контроль плотности ±0,01 г/см³ |

В отличие от литья, при спекании материал не расплавляется полностью. Вместо этого диффузия между частицами связывает их вместе, образуя почти твёрдую структуру.

2. Распространенные материалы для спекания металлов

Разные металлы ведут себя по-разному при нагревании. Вот наиболее распространённые спечённые материалы и их эксплуатационные характеристики:

| Материал | Плотность (г/см³) | Типичная прочность на растяжение (МПа) | Приложение |

|---|---|---|---|

| Железо + Медь | 6.8–7.2 | 350–500 | Шестерни, втулки |

| Нержавеющая сталь 316L | 7.6–7.9 | 520–620 | Медицинские детали, коррозионно-стойкие компоненты |

| Легированная сталь (4605, 4340) | 7.4–7.8 | 700–900 | Конструкционные детали, инструменты |

| Бронза | 7.3–7.6 | 300–450 | Подшипники, электрические контакты |

| Вольфрам / карбид | 14–15 | 1000+ | Режущие инструменты, быстроизнашивающиеся детали |

Совет: более плотная спеченная деталь обеспечивает лучшую прочность и износостойкость, но это также означает более длительные циклы спекания и более высокую стоимость.

3. Как спекание повышает эффективность производства

Спекание — это не просто изготовление деталей, это упрощение производства.

По сравнению с обработкой на станках с ЧПУ или литьем:

| Метод | Отходы | Размерная повторяемость | Эффективность затрат (массовое производство) |

|---|---|---|---|

| Обработка на станках с ЧПУ | Высокий | ±0,005 мм | Середина |

| Литье под давлением | Середина | ±0,05 мм | Средний–Высокий |

| Спекание металлов | Минимальный | ±0,03 мм | Высокий |

Вот почему спекание металлов так популярно в автомобильной, медицинской и бытовой электронике — оно позволяет изготавливать большие партии небольших, детализированных и высокопрочных деталей с очень стабильными допусками.

4. Управление ключевыми переменными процесса

Точность спекания зависит от того, насколько хорошо вы контролируете температуру, время и атмосферу.

| Переменная | Типичный диапазон | Эффект |

|---|---|---|

| Температура | 1100–1350 °С | Контролирует плотность и связь зерен |

| Время выдержки | 20–60 мин | Влияет на механическую прочность |

| Атмосфера | Водород, азот или вакуум | Предотвращает окисление |

| Скорость охлаждения | 10–50 °С/мин | Влияет на твердость и структуру |

Во многих современных печах для спекания датчики постоянно контролируют однородность температуры (±5 °C) для поддержания однородности деталей.

5. Реальный пример — спеченный зубчатый компонент

Производитель небольших автомобильных шестерен перешел с традиционной обработки на MIM+спекание с использованием порошка сплава Fe-2Cu-0.8C.

| Метрическая | До (обработано) | После (спекания) | Улучшение |

|---|---|---|---|

| Стоимость единицы продукции | 4,50 доллара | 2,10 доллара | ↓ 53% |

| Время производства | 12 мин | 5 мин | ↓ 58% |

| Размерная повторяемость | ±0,05 мм | ±0,02 мм | Лучше |

| Материальные отходы | ~40% | <5% | Значительно уменьшено |

Именно поэтому многие поставщики прецизионных деталей переходят на производство на основе спекания.

6. Варианты пост-спекания

После спекания детали могут пройти дополнительные этапы для точной настройки их характеристик:

-

Размеры: повышают точность размеров до ±0,01 мм.

-

Инфильтрация: добавляет бронзу или медь для повышения плотности.

-

Термическая обработка: повышает твердость и износостойкость

-

Обработка: для участков с жесткими допусками или поверхностных резьб

Заключение

Спекание металлов — это не загадочная технология, а практичный, управляемый данными процесс, объединяющий порошковую металлургию и высокоточное производство.

Речь идет об эффективности, повторяемости и использовании материала, особенно когда вы производите тысячи идентичных деталей с жесткими допусками.

Для таких отраслей, как автомобилестроение, медицина и производство оптических систем, это один из самых надежных способов достижения точности без отходов.

Делиться:

Инженерное руководство по подшипникам, изготовленным методом порошковой металлургии

Точность и производительность: мощь литьевых механизмов для металла